Safe torque off (STO) control circuit and system

A technology for controlling circuits and circuits, applied in electrical components, output power conversion devices, etc., can solve the problem of speed-adjustable electric equipment without STO control circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

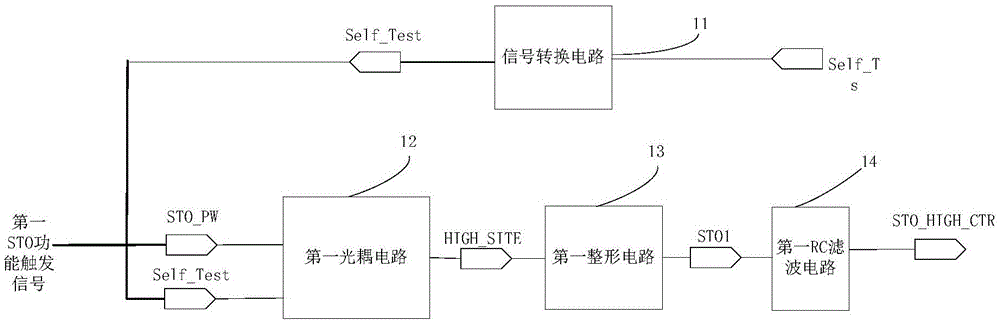

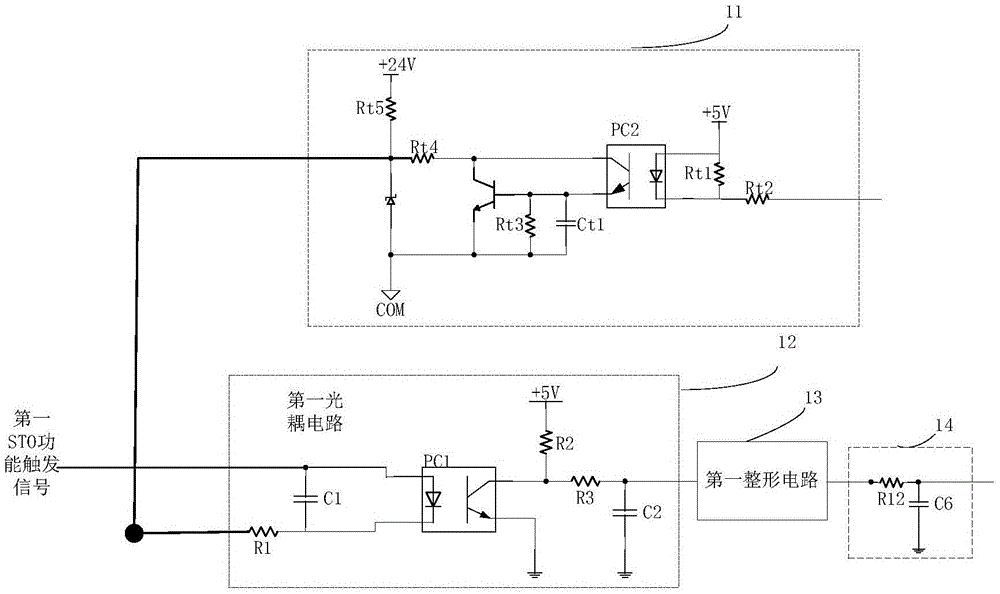

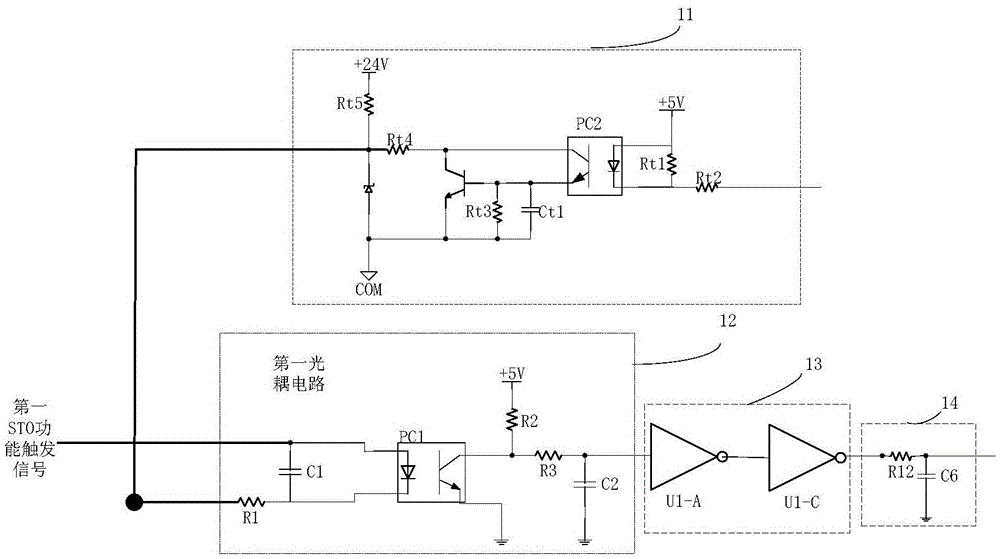

[0081] See figure 1 , which shows a schematic diagram of the logical structure of the STO control circuit provided in the present application, the STO control circuit includes: a signal conversion circuit 11 , a first optocoupler circuit 12 , a first shaping circuit 13 and a first RC filter circuit 14 .

[0082] The input terminal of the signal conversion circuit 11 is used for receiving the first narrow pulse signal.

[0083] In this embodiment, the first narrow pulse signal is used to realize the self-test of the STO control circuit.

[0084] In this embodiment, the first narrow pulse signal may specifically be output by the control module of the electric device corresponding to the STO control circuit.

[0085] The first input end of the first optocoupler circuit 12 is connected to the output end of the signal conversion circuit 11, the second input end of the first optocoupler circuit 12 is used to receive the first STO function trigger signal, the The output end of the ...

Embodiment 2

[0121] In this embodiment, another STO control circuit is expanded on the basis of the STO control circuit shown in Embodiment 1, please refer to Figure 7 , on the basis of the STO control circuit shown in Embodiment 1, it also includes: a second optocoupler circuit 15 having the same structure as the first optocoupler circuit 12; a second shaping circuit 15 having the same structure as the first shaping circuit 13 Circuit 16; a second RC filter circuit 17 having the same structure as the first RC filter circuit 14.

[0122] The first input end of the second optocoupler circuit 15 is connected to the output end of the signal conversion circuit 11, and the second input end of the second optocoupler circuit 15 is used to receive the first STO function trigger signal, The output end of the second optocoupler circuit 15 is connected to the input end of the second shaping circuit 16 , and the output end of the second shaping circuit 16 is connected to the input end of the second R...

Embodiment 3

[0145] In this embodiment, a STO control system is shown, please refer to Figure 10 , including electric equipment 151 and STO control circuit 152 .

[0146] For the composition and electrical principle of the STO control circuit 152 , please refer to the STO control circuit shown in Embodiment 1, which will not be repeated here.

[0147] It should be noted that the STO control circuit 152 implements the input of the first STO function trigger signal STO_PW through the emergency stop switch SW1 . The emergency stop switch SW1 is connected to the second input terminal of the first optocoupler circuit 12 . Among them, the emergency stop switch SW1 is a normally closed switch, which is disconnected when pressed to trigger the STO function.

[0148] When the STO function of the STO control circuit 152 is not triggered, the emergency stop switch SW1 is in a closed state, and the first STO function trigger signal STO_PW received by the second input end of the first optocoupler ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com