Method for making honeycomb-shaped cotton coat

A bread coat and honeycomb technology, which is applied in the field of garment processing, can solve the problems of uneven heat preservation and velvet leakage of bread clothes/down jackets/down quilts, and achieve the effects of improving social production efficiency, improving automation and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] see Figure 1~3 , in the embodiment of the present invention, a kind of preparation method of honeycomb bread garment, comprises the following steps:

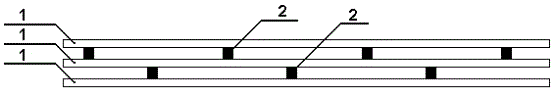

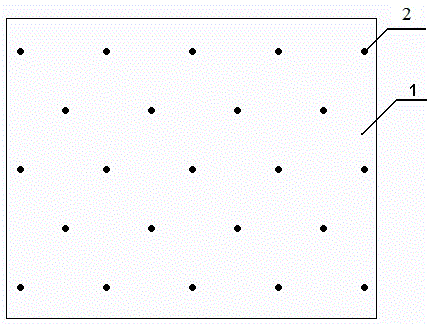

[0024] The first step: use more than three layers of fabrics to make special fabrics (ie multi-layer fabrics) for bread jackets / down jackets / duvets by bonding technology or multi-warp multi-layer jacquard weaving technology, see figure 1 , figure 2 (Three layers of fabric are used as an example in both pictures);

[0025] Step 2: Cut the multi-layer cloth according to the design size of the bread jacket / down jacket / duvet;

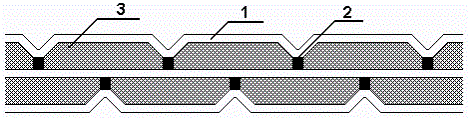

[0026] Step 3: Fill the insulation material in the multi-layer cloth, see image 3 (Take three-layer fabric as an example);

[0027] Step 4: Edge banding.

[0028] Seen from the cross-section, the filling units of the fabric made by the present invention are arranged in a honeycomb shape. Compared with the traditional bread jacket / down jacket / duvet structure, the weak parts of the heat preservat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com