Dust remover provided with electrostatic wheel

An electrostatic wheel and precipitator technology, applied in the field of electrostatic precipitators, can solve the problems of secondary dust raising, decreased air permeability, mesh blockage, etc., so as to extend the duration of continuous use, improve continuity, and prevent accumulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

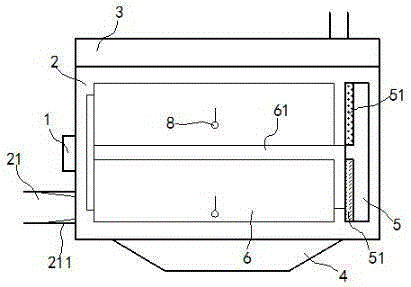

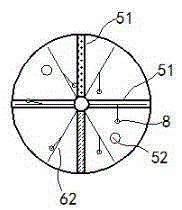

[0014] exist figure 1 , figure 2 In the shown embodiment, the electrostatic wheel dust collector includes an electrostatic generator 1, a dust removal chamber 2, a purification chamber 3 and an ash hopper 4; the dust removal chamber 2 and the purification chamber 3 are provided with an air inlet 21 and an exhaust gas outlet respectively. Mouth; the side wall of the dust removal chamber 2 is fixedly installed with a drive disk 5, and four conductive sheets 51 are embedded with rotational symmetry on the disk surface of the drive disk 5, and each of the conductive sheets 51 is insulated from each other; the four conductive sheets 51 is electrically connected to the positive pole, ground wire, negative pole, and ground wire of the electrostatic generator 1 in a clockwise direction; the two conductive sheets 51 connected to the ground wire are at the same horizontal line; an electrostatic wheel 6 is also movable in the dust removal chamber 2, The rotating shaft 61 of the electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com