Pipe cleaner for removing black powder

A pipe cleaner and black powder technology, applied in the field of pipe cleaners, can solve the problems of increased working time and pigging risk, unsatisfactory cleaning effect of black powder, and incomplete removal of cleared materials, etc., to improve the carrying and cleaning of black powder. The ability of the pig to reduce the risk of operating errors or equipment damage due to frequent use, and the effect of reducing the number of times through the pig

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

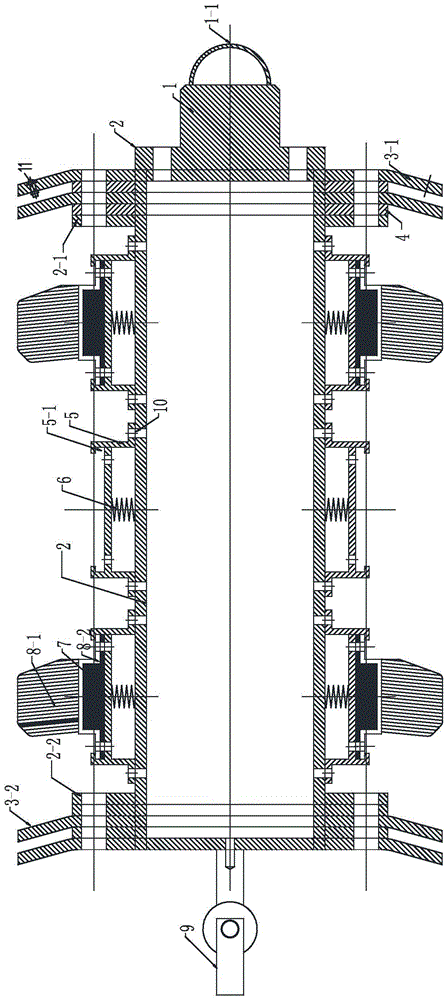

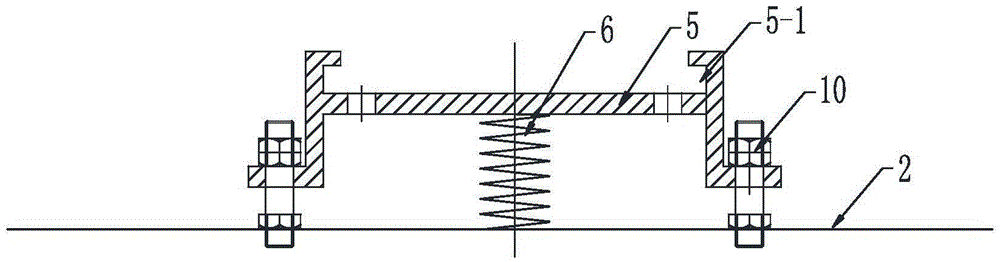

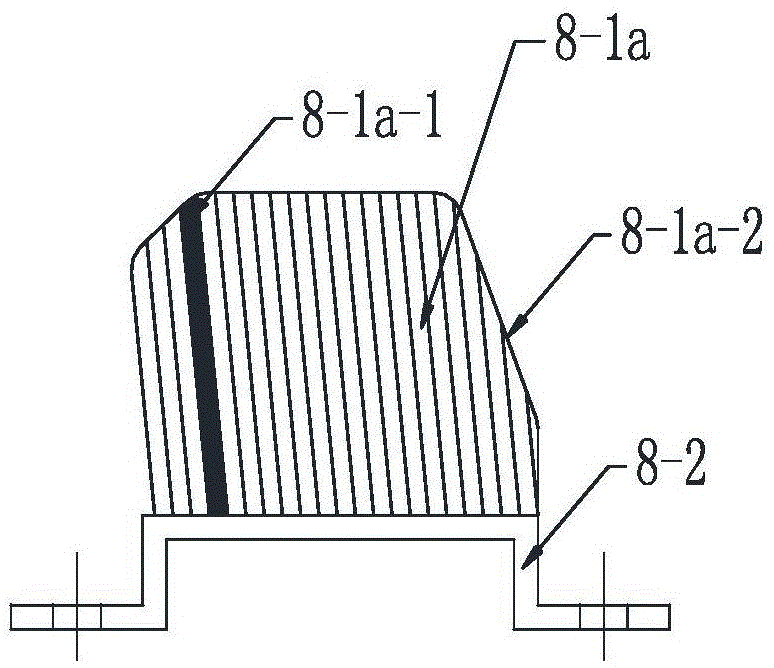

[0022] see Figure 1 ~ Figure 4 , a black powder pipe cleaning device, including a hollow main shaft 2 closed at both ends, a front flange 2-1 is fixed on the outer circle of the front part of the hollow main shaft 2, and a front flange 2-1 is fixed on the outer circle of the front part of the hollow main shaft 2. A rear flange 2-2 is fixedly installed on the outer circle, and a pipeline sealing disc I3-1 fixedly connected to it is provided in front of the front flange 2-1, and a The rear is provided with a pipe sealing disc II 3-2 fixedly connected to it, and at least A ring of steel brush groups, each ring of steel brush groups is composed of a plurality of steel brush assemblies uniformly distributed along the circumference, each of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com