Wheel-leg composite spherical surface parallel mechanism

A parallel and motor-driven technology, applied in the field of robotics, can solve problems such as the difficulty of sealing joint drive motors, large self-weight and load ratios, and complex leg mechanisms, etc., to achieve a compact wheel-leg composite structure, fast response speed, and save joints. driving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

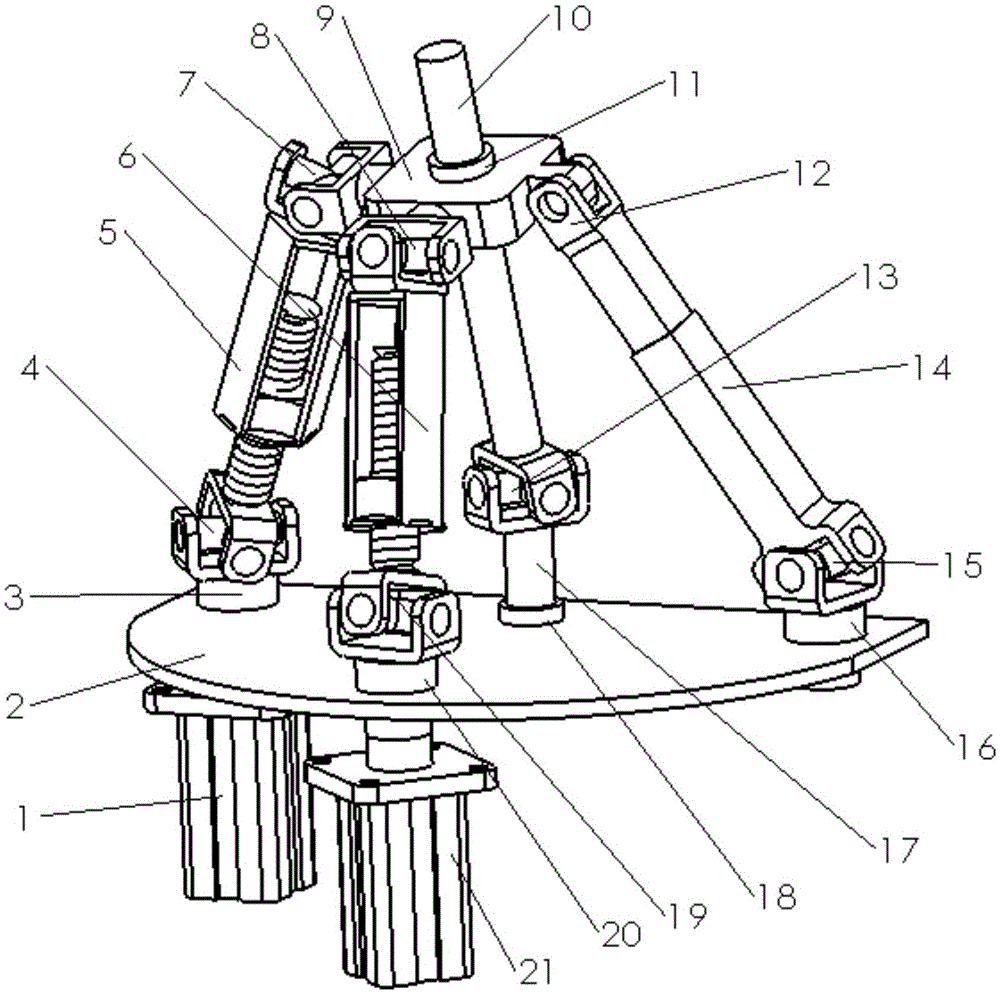

[0019] On the one hand, the present invention provides a wheel-leg compound spherical parallel mechanism, such as figure 1 As shown, including static platform 2 and dynamic platform 9, wherein:

[0020] The static platform 2 is a semicircle, and the dynamic platform 9 is a square shape;

[0021] Between one end of the static platform 2 and one end of the dynamic platform 9, the first rotating pair 3, the first universal joint 4, the first screw pair 5 and the second universal joint 7 are arranged in sequence, thereby forming the first RUHU kinematic branch chain , wherein the first revolving pair 3 is driven by the first motor 1 arranged on the static platform 2;

[0022] Between the upper end of the static platform 2 and the upper end of the dynamic p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com