Printing machine device with measurement function

A printing press and torque measurement technology, applied in measuring devices, printing presses, rotary printing presses, etc., can solve the problems of low precision and large measurement result error, and achieve the effect of high precision and small measurement result error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

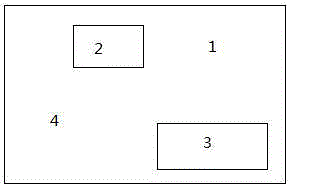

Image

Examples

Embodiment Construction

[0009] The present invention will be further explained below in conjunction with the accompanying drawings.

[0010] A printing press device with measurement, characterized in that it includes a printing machine (1), a motor (2), and a non-contact torque measuring device (3); the non-contact torque measuring device (3) and the motor ( 2) No physical contact occurs; the non-contact torque measuring device includes a power supply, a generator, a sensor and a transmission interface.

[0011] The non-contact torque measuring device of the present invention adopts a non-contact measuring method, and the measuring device does not have physical contact with the motor, which reduces the error of the measurement result and improves the precision.

[0012] The above content is only a preferred embodiment of the present invention, and is not intended to limit the implementation of the present invention. Appropriate modifications or modifications made by those skilled in the art a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com