Tool for measuring wall thickness of casing

A casting and tool technology is applied in the field of a measuring tool used to measure the wall thickness of a casting in the process of casting a core. Fast, small deviation of results, effect in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

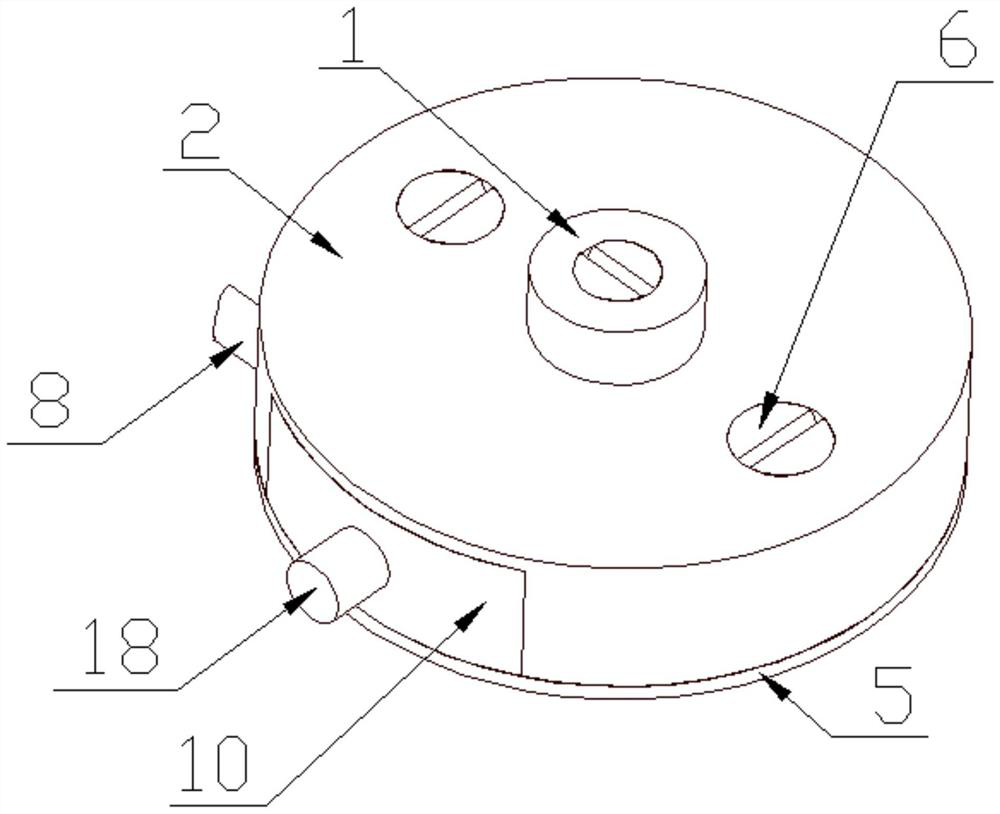

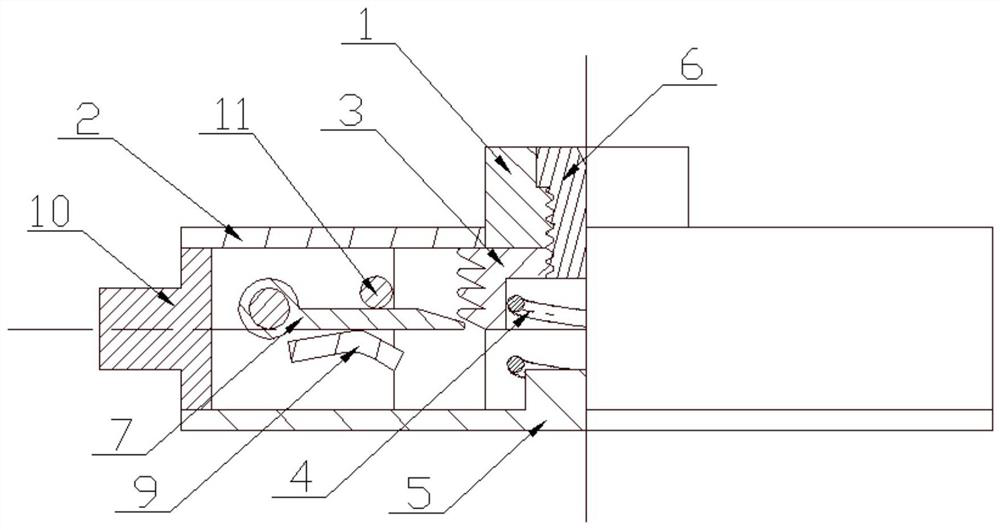

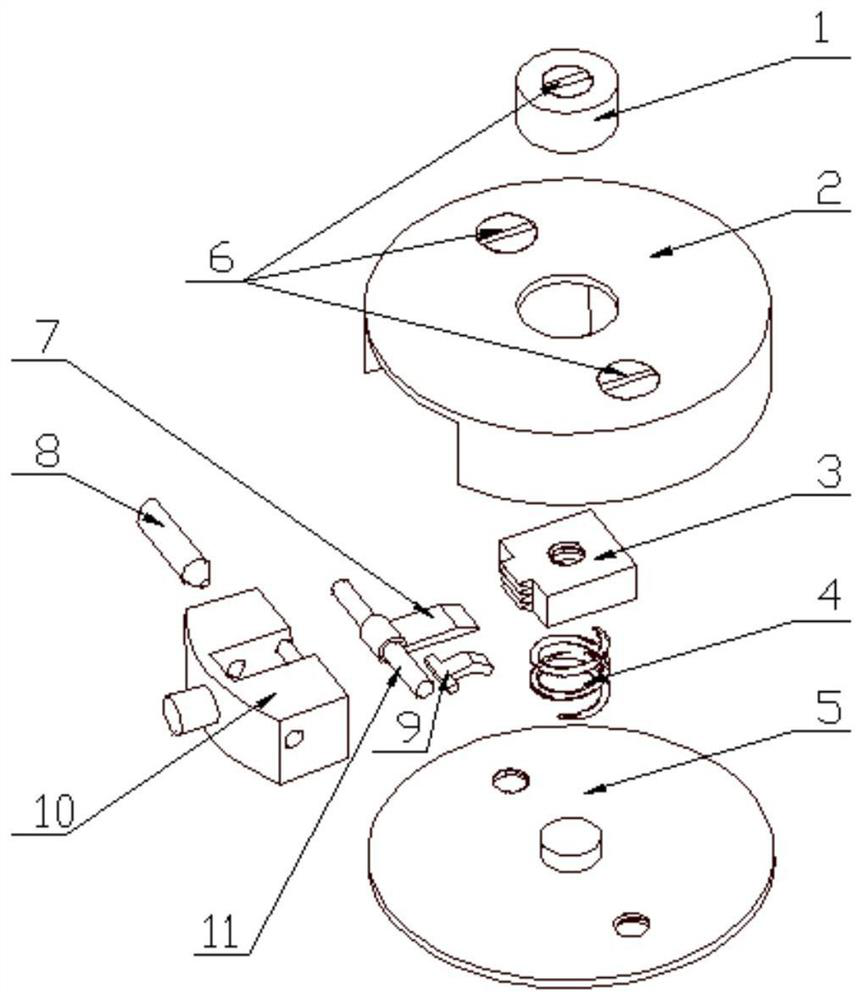

[0024] A tool for measuring the wall thickness of a casting, including an upper seat, a base, a reset mechanism, a push rod, and a ratchet block.

[0025] The outer contour of the upper seat and the base can be cylindrical or cuboid, the diameter and side distance of the upper seat and the base are consistent, the size can be 40-100mm, the height of the upper seat can be 9-25mm, and the thickness of the base can be 1-5mm. There are screw holes on the top, and they are fastened together by screw connection.

[0026] The inside of the upper seat is provided with a first ladder structure and a second ladder structure. The first ladder structure is a cuboid with a square cross section, side length 10-30mm, and height 8-20mm; the spine block set in the first ladder structure is a cuboid with a square cross-section, height 4-10mm, and one side of the spine block. There is a sawtooth block on the top, the height of each sawtooth on the sawtooth block is 1-2mm, the length of the sawt...

Embodiment 2

[0029] The upper seat 2 of the casting wall thickness tool in the present embodiment is a cylinder, and a circular base 4 is arranged correspondingly. The uppermost end of the upper seat 2 and the base 4 are symmetrically provided with screw holes on both sides of the horizontal centerline, and are screwed by the top screw 6. Upper seat 2 and base 5 are fastened together.

[0030] Boss is designed at the very center of base 5, and stage clip 4 is connected and fastened on the boss, and the radius of the inner ring of stage clip 4 is consistent with the radius of the boss of the base.

[0031] A stepped structure is provided inside the upper seat 2 , including a first stepped structure 13 and a second stepped structure 15 . The uppermost part of the upper seat 2 is provided with a through hole downwards via the vertical center line, and the ejector rod 1 can rotate up and down inside. The ejector rod 1 is provided with a top wire 6 and a sleeve along the center line. On the on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com