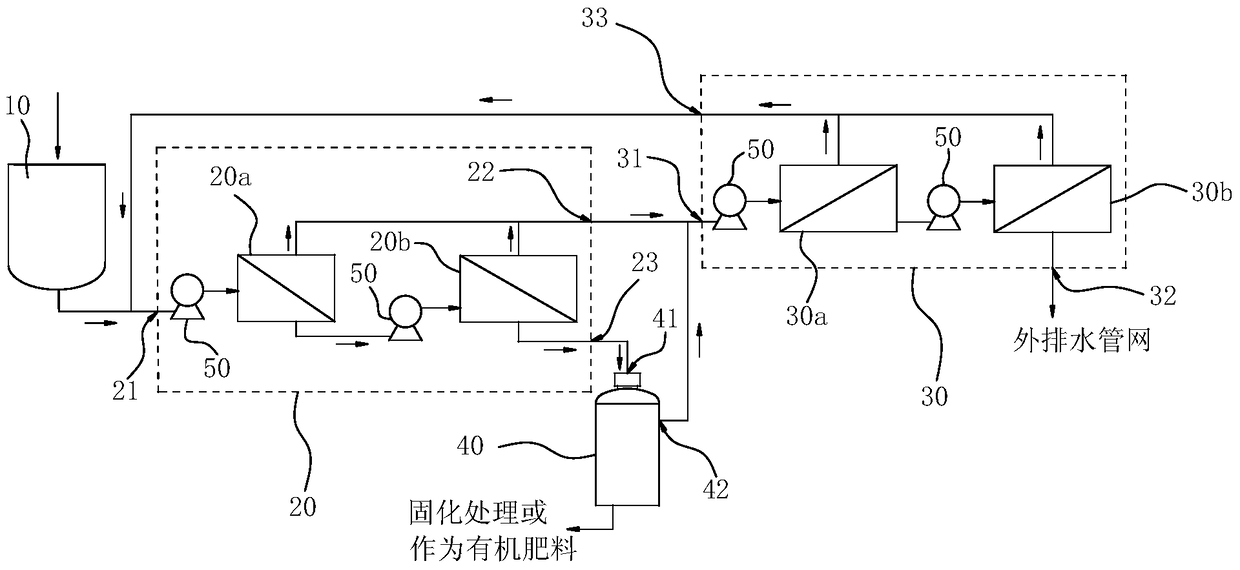

Domestic waste leachate treatment system

A treatment system and domestic garbage technology, applied in water/sewage treatment, multi-stage water/sewage treatment, heating water/sewage treatment, etc., can solve the problem that the qualified rate does not exceed 85%, the amount of concentrated waste liquid is large, and cannot be treated again And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] 1. Take the six batches of leachate after biochemical and ultrafiltration pretreatment, respectively pass through the first-level nanofiltration unit 20a and the second-level nanofiltration unit 20b for parallel nanofiltration treatment, and the results are shown in Table 1 below. It can be seen from Table 1 that the leachate can be concentrated to more than 60 times after the primary nanofiltration treatment, and the conductivity removal rate is as high as 77%.

[0016] Table 1 Primary nanofiltration treatment results

[0017]

[0018]

Embodiment 2

[0020] 1. Take the third batch of samples in Example 1 of 1000ml, and concentrate by vacuum evaporation and concentration after primary nanofiltration concentration of 60 times, and monitor the remaining amount and boiling point of the concentrate during the concentration process to determine that the concentrate is evaporating The multiples that can be concentrated in the device, the results are shown in Table 2 below, as can be seen from the table, the concentrated solution can be normally concentrated 3 times, when the remaining content of the concentrated solution is about 200ml, and the concentration of the concentrated solution reaches 5 times, the feed liquid The nature changed drastically.

[0021] Atmospheric pressure evaporation concentration data of the concentrate in table 2

[0022] serial number

Concentrate volume / mL

Boiling point / ℃

Remark

1

~1000

1

103.0

2

~900

104.0

3

...

Embodiment 3

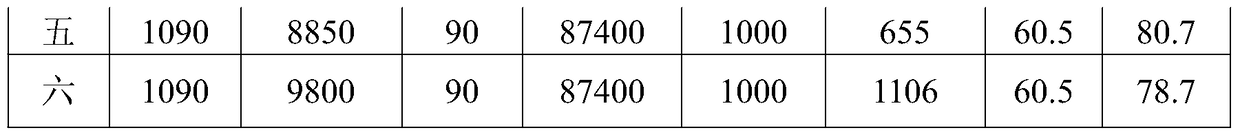

[0031] The supernatant produced after the first-level nanofiltration concentration of each batch of samples in Example 1 was respectively passed through the second-level nanofiltration unit one 30a and the second-level nanofiltration unit 30b to carry out the second-level nanofiltration treatment, and the first-level and second-level nanofiltration The supernatant liquid after stage nanofiltration was tested for COD value, and the results are shown in Table 5 below. It can be seen from the table that the COD value of the permeate after secondary nanofiltration is less than 100 mg / l, which meets the first-level discharge requirements stipulated in the national comprehensive sewage discharge standard.

[0032] Table 5 Supernatant COD detection of primary and secondary nanofiltration treatment

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com