LCP (liquid crystal polyester) composition

A technology of liquid crystal polyester and composition, which is applied in the direction of liquid crystal materials, chemical instruments and methods, etc., can solve the problems of fluidity and improvement not mentioned, and achieve the effect of improving high temperature heat resistance stability and fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

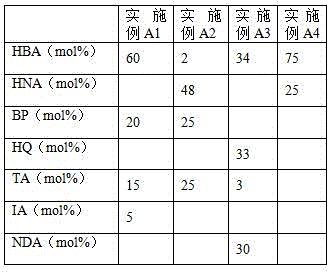

Embodiment A1-A4

[0065] Embodiment A1-A4: the preparation of liquid crystal polyester

[0066] In the reaction kettle equipped with a stirrer, a thermometer, a nitrogen inlet pipe and a reflux condensing device, respectively add repeating units derived from aromatic hydroxycarboxylic acids, repeating units derived from aromatic diols and aromatic The repeating unit of dicarboxylic acid, and add a certain proportion of acetic anhydride as an acylating agent; then pass nitrogen into the reactor for replacement; start stirring, and heat the reaction mixture from room temperature to 140°C-160°C in nitrogen flow, Reflux at this temperature for 1 hour to 3 hours; then continue to heat up, and heat the mixture from 140°C to 160°C to 300°C to 350°C over 2 hours to 4 hours, during which unreacted acetic anhydride and by-products are distilled off. Reaction product acetic acid; In the final polycondensation stage, the reaction system is decompressed, and judged by observing that the torque rises as the ...

Embodiment 1-12 and comparative example 1-6

[0069] Examples 1-12 and Comparative Examples 1-6: Preparation of Liquid Crystal Polyester Composition

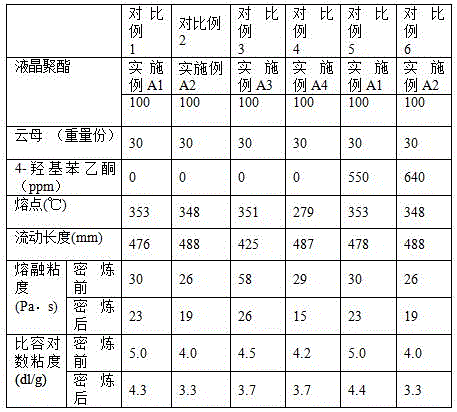

[0070] According to the proportioning of Table 2, after the liquid crystal polyester, filler, 4-hydroxyacetophenone and / or various additives prepared by the examples A1-A4 are mixed uniformly with a high-speed mixer, they are added to a twin-screw extruder at 280RPM Melting and mixing at a screw speed of -320RPM, the temperature of the screw barrel is 290°C-355°C, extruding, cooling, and pelletizing to obtain a liquid crystal polyester composition. The melting point, flow length, melt viscosity and specific logarithmic viscosity of the obtained liquid crystal polyester composition are listed in Table 2.

[0071] Table 2

[0072]

[0073] Continued Table 2

[0074]

[0075] From the comparison of Examples 1-12 and Comparative Examples 1-6 in Table 2, it can be seen that the present invention adds 4-hydroxyacetophenone based on the total amount of liquid crystal polye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com