Liquid crystal polyester composition

A technology of liquid crystal polyester and composition, applied in liquid crystal materials, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A1-A4

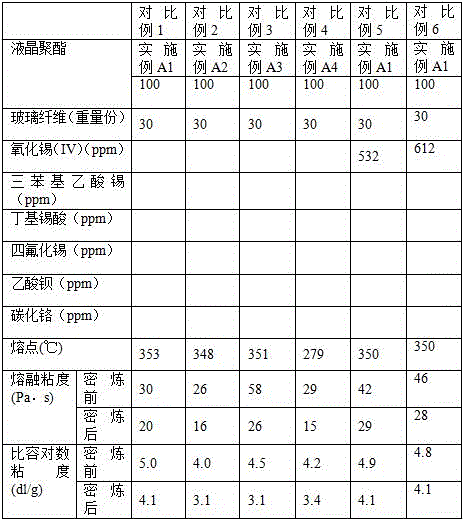

[0083] Embodiment A1-A4: the preparation of liquid crystal polyester

[0084] Add the repeating units derived from aromatic hydroxycarboxylic acid, the repeating units derived from aromatic diol and the repeating units derived from aromatic Repeating unit of carboxylic acid, and add a certain proportion of acetic anhydride as acylating agent; then pass nitrogen into the reaction kettle for replacement; start stirring, and heat the reaction mixture from room temperature to 140°C-160°C in nitrogen flow, Reflux at this temperature for 1 hour to 3 hours; then continue to heat up, and heat the mixture from 140°C to 160°C to 300°C to 350°C over 2 hours to 4 hours, during which unreacted acetic anhydride and side reactions are evaporated Product acetic acid; In the final polycondensation stage, the reaction system is decompressed, and judged by observing that the torque rises as the end point of the reaction; at this time, the prepolymer in the melt state is discharged through the di...

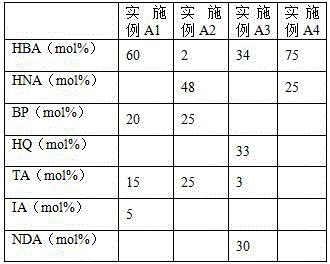

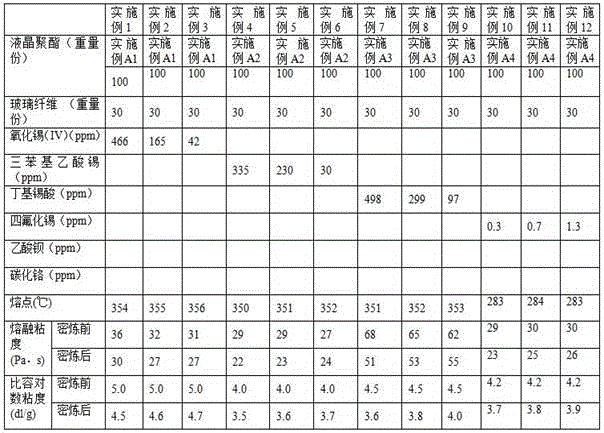

Embodiment 1-17 and comparative example 1-6

[0087] Examples 1-17 and Comparative Examples 1-6: Preparation of Liquid Crystal Polyester Composition

[0088] According to the proportioning in Table 2, the obtained liquid crystal polyester, filler, tin-containing compound and / or barium-containing compound and / or chromium-containing compound, and / or various additives prepared by Examples A1-A4 are uniformly mixed with a high-speed mixer , into a twin-screw extruder, melted and mixed at a screw speed of 280RPM-320RPM, and the temperature of the screw barrel is 290°C-355°C, extruded, cooled, and pelletized to obtain a liquid crystal polyester composition. The melting point, melt viscosity and specific logarithmic viscosity of gained liquid crystalline polyester composition are listed in Table 2;

[0089] Wherein, the content of metal tin element, metal barium element and metal chromium element in the liquid crystal polyester composition is determined by the actual addition amount of tin-containing compound, barium-containing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com