Preparation method of composite optical precoating film

A pre-coating film and composite technology, which is applied in the field of optical films, can solve the problems that the back-coating film cannot be made and depends on imports, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

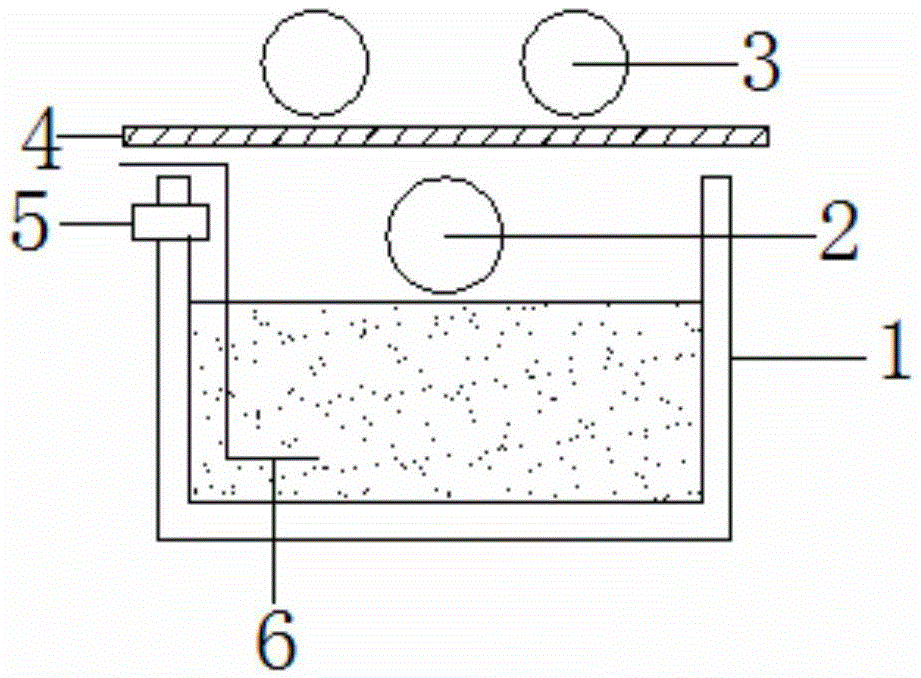

Method used

Image

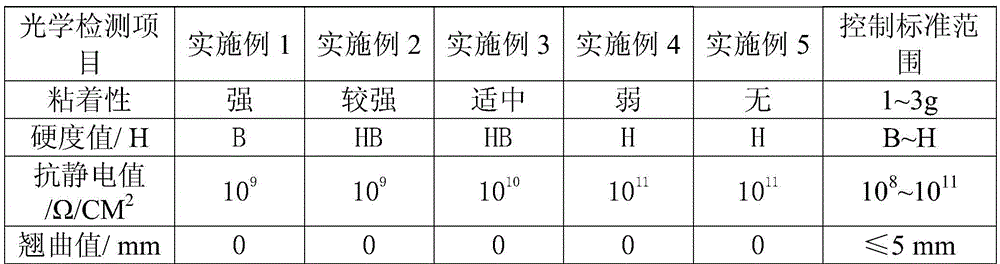

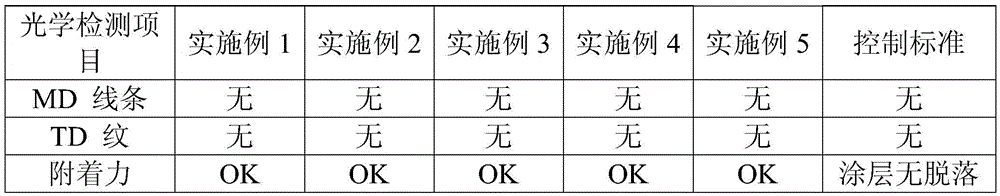

Examples

Embodiment 1

[0025] A preparation method of a composite optical precoat film, said preparation method comprising the following steps:

[0026] (1) Raw material preparation of the coating liquid: the composition by mass of the coating liquid is as follows: 20 parts of UV resin, 20 parts of toluene, 20 parts of methyl ethyl ketone, 2 parts of acrylic microbeads of 2-5 μm, and 20 parts of acrylic pressure-sensitive glue;

[0027] (2) Preparation of light diffusing agent coating liquid: mix 2-5μm acrylic microbeads, toluene and butanone, stir at room temperature for 30 minutes, control the speed at 500 rpm / min; then add UV resin and acrylic pressure-sensitive glue, control the speed 500rpm / min, after stirring at room temperature for 30min, the light diffusing agent coating was obtained;

[0028] (3) Apply the light diffusing agent coating prepared in step (2) evenly on the upper film, and then cover the lower film. The coating process adopts a dimple coating method, and a combination of UV cur...

Embodiment 2

[0033] A preparation method of a composite optical precoat film, said preparation method comprising the following steps:

[0034] (1) Raw material preparation of the coating solution: the composition of the coating solution by mass is as follows: 25 parts of UV resin, 25 parts of toluene, 25 parts of methyl ethyl ketone, 4 parts of acrylic microbeads of 2-5 μm, and 15 parts of acrylic pressure-sensitive glue;

[0035] (2) Preparation of light diffusing agent coating liquid: mix 2-5μm acrylic microbeads, toluene and butanone, stir at room temperature for 30 minutes, control the speed at 600rpm / min; then add UV resin and acrylic pressure-sensitive glue, control the speed 600rpm / min, after stirring at room temperature for 30min, the light diffusing agent coating was obtained;

[0036] (3) Apply the light diffusing agent coating prepared in step (2) evenly on the upper film, and then cover the lower film. The coating process adopts a dimple coating method, and a combination of UV ...

Embodiment 3

[0041] A preparation method of a composite optical precoat film, said preparation method comprising the following steps:

[0042] (1) Raw material preparation of the coating liquid: the composition of the mass parts of the coating liquid is as follows: parts, 20 parts of acrylic pressure-sensitive adhesive;

[0043] (2) Preparation of light diffusing agent coating liquid: mix 2-5μm acrylic microbeads, toluene and butanone, stir at room temperature for 30 minutes, control the speed at 700rpm / min; then add UV resin and acrylic pressure-sensitive glue, control the speed 700rpm / min, after stirring at room temperature for 30min, the light diffusing agent coating was obtained;

[0044] (3) Apply the light diffusing agent coating prepared in step (2) evenly on the upper film, and then cover the lower film. The coating process adopts a dimple coating method, and a combination of UV curing and thermal curing is used during coating. The method of curing operation;

[0045] (4) Test: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com