Real leather manufacturing method

A production method and leather technology are applied in the fields of leather insoles, leather production, and leather shoes and boots, which can solve the problems of inability to absorb sweat, chemical substances pollute the environment, and chemical substances are harmful to human health, etc., and achieve excellent application performance and do not pollute the environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

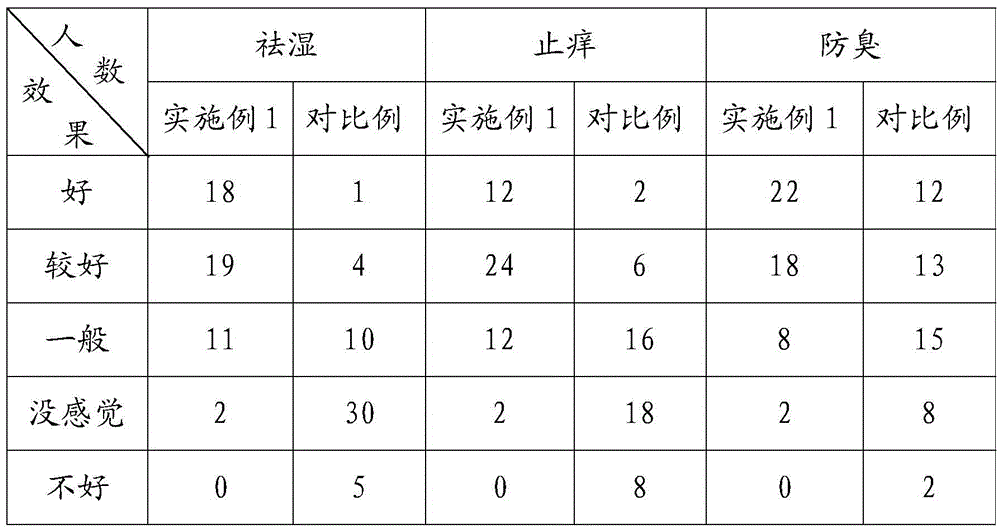

Examples

Embodiment 1

[0030] A kind of genuine leather insole, the manufacture method of making the genuine leather of described genuine leather insole, carry out according to the following steps:

[0031] 1) Distillation: choose fresh wormwood to chop, add distilled water and mix, the weight ratio of fresh wormwood and distilled water is 1:3, then carry out distillation to obtain wormwood distillate;

[0032] 2) liquid separation: add sodium chloride to the wormwood distillate obtained in step 1), then use a separating funnel to carry out liquid separation after oscillating, shaking up and standing to obtain an oil layer and a water layer; the oil layer is separated, Obtain the crude essential oil of wormwood;

[0033] 3) Oil production: add anhydrous sodium sulfate to the crude wormwood essential oil obtained in step 2), and filter to obtain the wormwood essential oil for subsequent use;

[0034] 4) Soup: Chopped fresh wormwood and mixed with distilled water for heating and boiling. The weight r...

Embodiment 2

[0039] A kind of genuine leather cotton boots, the manufacture method of the genuine leather of described genuine leather cotton boots is carried out according to the following steps:

[0040] 1) Distillation: choose fresh wormwood to chop, add distilled water and mix, the weight ratio of fresh wormwood and distilled water is 1:5, then distill for 2 hours to obtain wormwood distillate;

[0041] 2) liquid separation: add sodium chloride to the wormwood distillate obtained in step 1), then use a separating funnel to carry out liquid separation after oscillating, shaking up and standing to obtain an oil layer and a water layer; the oil layer is separated, Obtain the crude essential oil of wormwood;

[0042] 3) Oil production: add anhydrous sodium sulfate to the crude wormwood essential oil obtained in step 2), and filter to obtain the wormwood essential oil for subsequent use;

[0043] 4) Soup: Chopped fresh wormwood, mixed with distilled water, and then boiled. The weight ratio...

Embodiment 3

[0048] A kind of cowhide leather shoes, the cowhide that makes described cowhide leather shoes is carried out according to the following steps:

[0049] 1) Distillation: Chopped fresh wormwood, mixed with distilled water, the weight ratio of fresh wormwood and distilled water was 1:4, and then distilled for 1.5 hours to obtain wormwood distillate;

[0050] 2) liquid separation: add sodium chloride to the wormwood distillate obtained in step 1), then use a separating funnel to carry out liquid separation after oscillating, shaking up and standing to obtain an oil layer and a water layer; the oil layer is separated, Obtain the crude essential oil of wormwood;

[0051] 3) Oil production: add anhydrous sodium sulfate to the crude wormwood essential oil obtained in step 2), and filter to obtain the wormwood essential oil for subsequent use;

[0052] 4) Soup: Chopped fresh wormwood, mixed with distilled water, and boiled. The weight ratio of fresh wormwood to distilled water is 1:3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com