Method using reinforcing rib to enhance rebound force of elastic cushion board, and elastic cushion board

An elastic backing plate and reinforcing rib technology, which is applied in the field of rail transportation, can solve the problems of affecting the vibration damping performance and service life of the rail system, lateral sliding of the rail and the iron backing plate, and difficulty in meeting the needs of railway transportation, etc. The effect of faster rebound, reduced vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

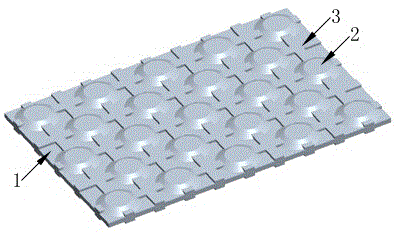

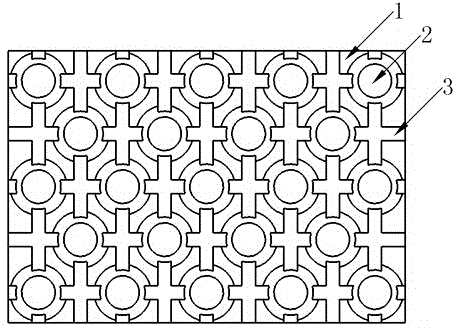

[0047] Such as figure 1 , figure 2 with image 3 As shown, a reinforcing rib reinforced elastic pad includes a plate body 1; there are protrusions 2 on the upper and lower surfaces of the plate body 1, and the protrusions 2 are truncated cones; in the horizontal and vertical directions of the protrusions 2 There are stiffeners 3 arranged, which are horizontal stiffeners and vertical stiffeners; the shape of the stiffeners 3 is a discontinuous strip, and the two ends of the length direction of the stiffeners 3 are connected with two protrusions 2 respectively, and horizontal and vertical The length line of the ribs in the two directions passes through the center of the protrusion 2, so that the protrusion 2 is pulled and connected by four symmetrical ribs in the horizontal and vertical directions, and the horizontal and vertical ribs are interlaced and connected to each other. The "cross"-shaped reinforcing ribs are combined with the protrusions 2 to form a mesh-like elasticity ...

Embodiment 2

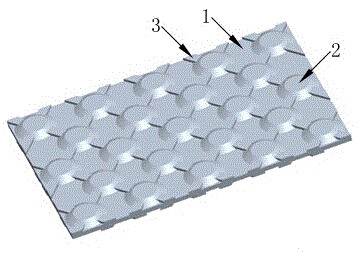

[0052] Such as Figure 4 , Figure 5 with Image 6 As shown, a reinforcing rib reinforced elastic backing plate includes a plate body 201; there are protrusions 202 on the upper and lower surfaces of the plate body 201, and the protrusions 202 are truncated cones; the protrusions 202 are arranged obliquely and symmetrically. 4 stiffeners 203, and 4 stiffeners 203 are perpendicular to each other; the shape of the stiffener 3 is a discontinuous strip, and the two ends of the longitudinal direction of the stiffener 203 are respectively connected to two protrusions 202, and are diagonal The line connecting the ribs in the two directions in the length direction passes through the center of the protrusion 202, so that the protrusion 202 is connected by symmetrical 4 ribs in the four directions; the 4 ribs and the protrusion 202 form a mesh The mesh structure elasticity enhancer, through the mesh structure elasticity enhancer, enhances the resilience of the elastic pad and the ability ...

Embodiment 3

[0056] Such as Figure 7 , Figure 8 with Picture 9 As shown, a reinforcing rib reinforced elastic backing plate includes a plate body 301; there are protrusions 302 on the upper and lower surfaces of the plate body 301, and the protrusions 302 are truncated; in the peripheral gap between the protrusions 302 A continuous reinforcing rib 303 is arranged obliquely. The reinforcing rib 303 surrounds the periphery of the protrusion 302, and the reinforcing rib 303 is connected with 4 edges of the periphery of the protrusion 302 to form a "mouth"-shaped annular reinforcing rib around the protrusion 302. "" shaped ring-shaped stiffeners are pulled at four points in two directions to enhance the horizontal rigidity and rebound strength of the elastic pad; the ring-shaped stiffeners and protrusions 302 form a net-like mesh structure elastic reinforcement, through the net-like structure The elastic enhancer enhances the resilience of the elastic pad and the ability to resist horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com