Open-cut tunnel open-type main structure side wall Bailey support formwork and its construction technology

A technology for main structures and open-cut tunnels, which is applied in the direction of basic structure engineering, underwater structures, artificial islands, etc., and can solve the problems affecting the construction progress of other structural sections, the heavy workload of dismantling steel pipe supports, and the impact on the waterproof quality of structural side walls, etc. problems, to achieve the effect of good appearance quality, improved construction conditions, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

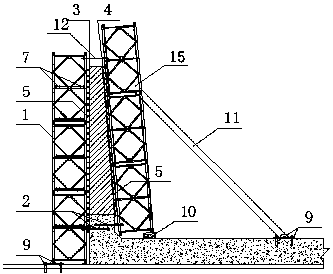

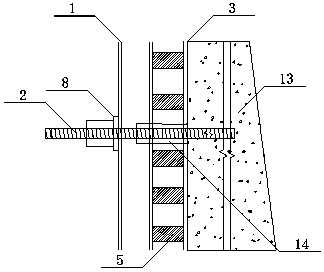

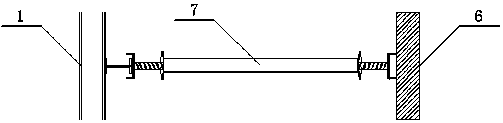

[0014] Such as figure 1 As shown, the open-cut tunnel open-type main structure side wall Bailey frame support formwork includes the outer formwork 3 and the inner formwork 4 opposite to each other on the inner side, the first Bailey truss 1 is arranged on the outer side of the outer formwork 3, and the second Bailey truss is set on the outer side of the inner formwork 4 Ray truss 15, connecting rod 12 is set between the upper part of the first Bailey truss 1 and the second Bailey truss 15, and the lower part of the first Bailey truss 1 and the second Bailey truss 15 are provided with embedded screw 2, the second The upper part of the Bailey truss 15 is inclined to the first Bailey truss 1 . This structure takes advantage of the form characteristics of the open main structure of the open-cut tunnel, and uses the Bailey frame to form the load support. The construction accuracy of the template is improved, the waterproof quality of the side wall is guaranteed, and the constructi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com