Standard single roof structure for supporting aluminum formwork special for lightning protection of high-speed rail

An aluminum formwork and lightning protection technology, which is applied in the direction of building types, buildings, towers, etc., can solve the problems that the single roof cannot be adjusted in height, the scope of application is small, and the needs of rapid construction of high-speed rail cannot be met, and it has a wide application scope and good stability. , the effect of convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

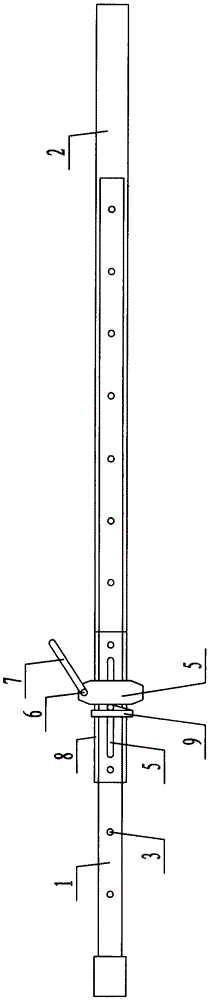

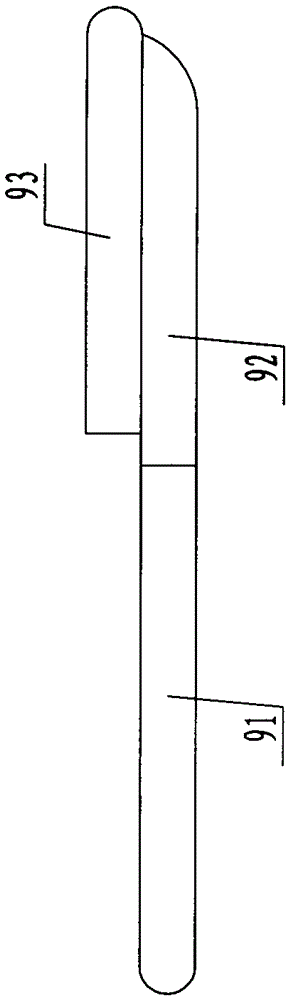

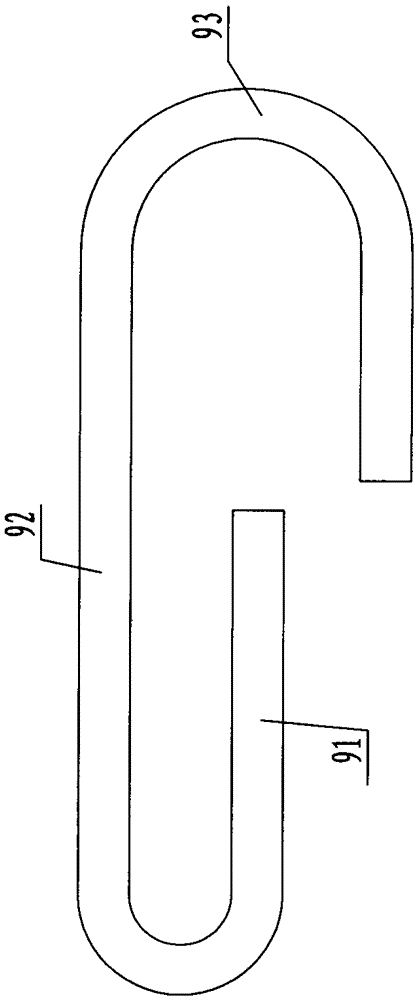

[0011] Such as figure 1 , figure 2 , image 3 As shown, the standard single-roof structure is supported by the special aluminum formwork for high-speed rail lightning protection, including: an inner jacking tube 1 and an outer jacking tube 2 sleeved on the inner jacking tube 1. Position hole 3, on one end of described outer push cylinder 2, is welded with the threaded sleeve 4 that cooperates with inner push cylinder 1, is provided with the bushing nut 5 that cooperates with it on described threaded sleeve 4, in place The casing nut 5 is provided with a handle 7 through a rivet 6, and a limiting groove 8 cooperating with the limiting hole 3 is symmetrically arranged on both sides of the threaded sleeve 4, and the limiting groove 8 and the limiting The hole 3 is provided with an annular bolt 9 that cooperates with i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com