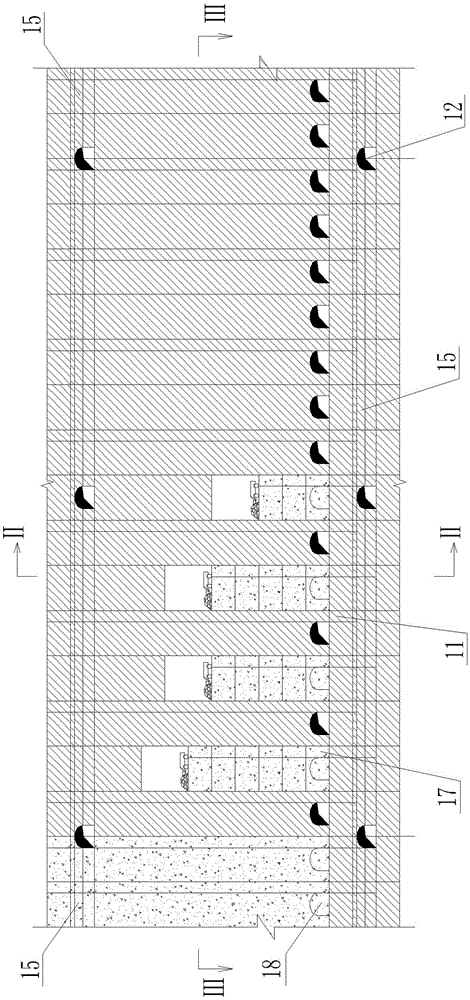

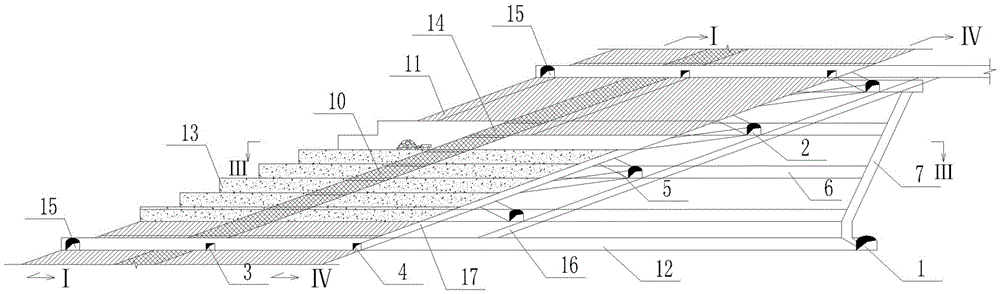

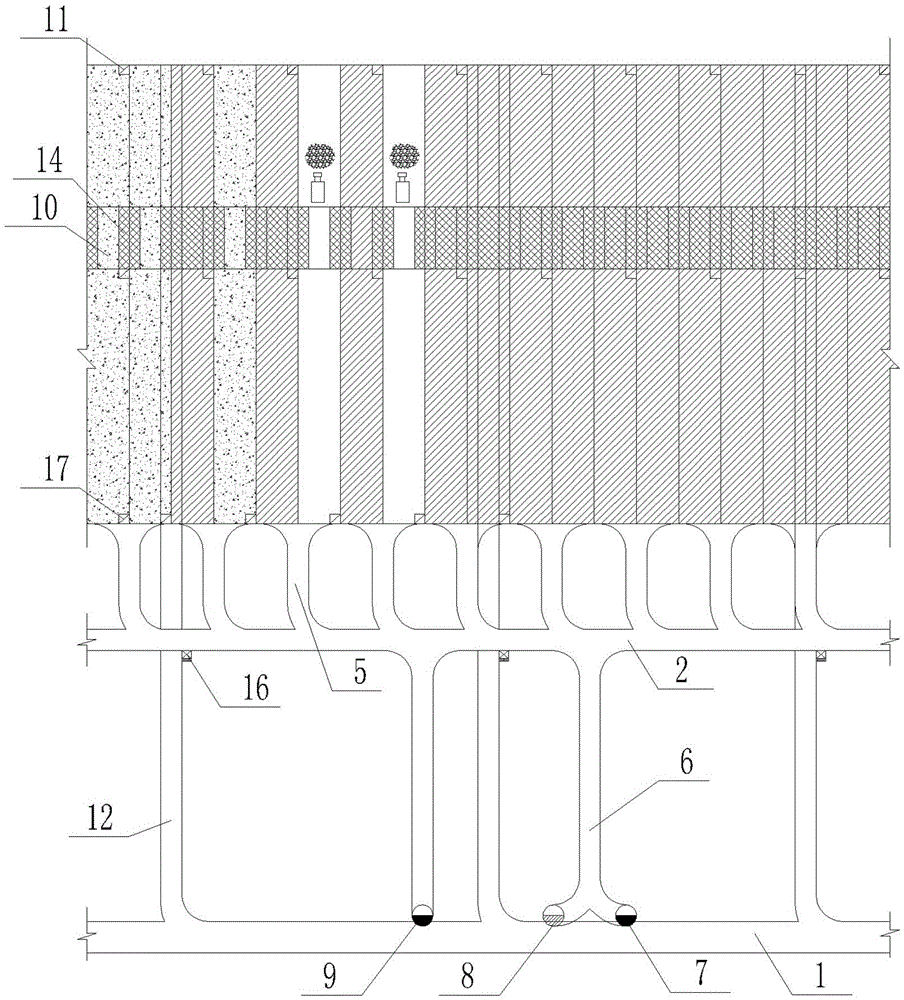

Filling mining method for continuous backstoping of gently inclined parallel medium thick ore body group

A backfill mining method, inclined-parallel technology, applied in the fields of backfill, ground mining, mining equipment, etc., can solve the problems of difficulty in realizing the separation of two kinds of ores and waste rock, small mining ratio, and small dilution loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Take Laohudong Phosphate Mine of Guizhou Green Phosphate Development Co., Ltd. as an example.

[0034] Laohudong Phosphate Mine is located in the groundwater enrichment area at the dipping end of the entire dolomite anticline, and the roof of the mine is the main aquifer in the mining area. The Yangen River on the surface flows through the mining area from south to north, and is the mining deposit under the water body. There are 364647kt of 111b / 331+122b / 332+333 ore in the mining area, with an average grade of P 2 o 5 25.95%. The ore body is a gently inclined medium-thick ore body, and the main occurrence elevation is 0m~800m. The ore body has two layers. The upper layer is the b ore layer with a dip angle of 15.2o and an average thickness of 9.13m. 16.95m, it is a silicon-calcium phosphorite ore, which is suitable for producing high-value yellow phosphorus. Mining needs to consider separate mining and transportation. There is an interlayer between the a ore layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com