Novel ball valve opening and closing piece and spherical monoclinic weld joint type all-welded ball valve comprising same

A technology of fully welded ball valves and opening and closing parts, which is applied in the direction of cocks including cutting devices, valve devices, engine components, etc., can solve the problems of easy abrasion and damage, maintain contact friction, etc., to ensure welding quality and high material utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

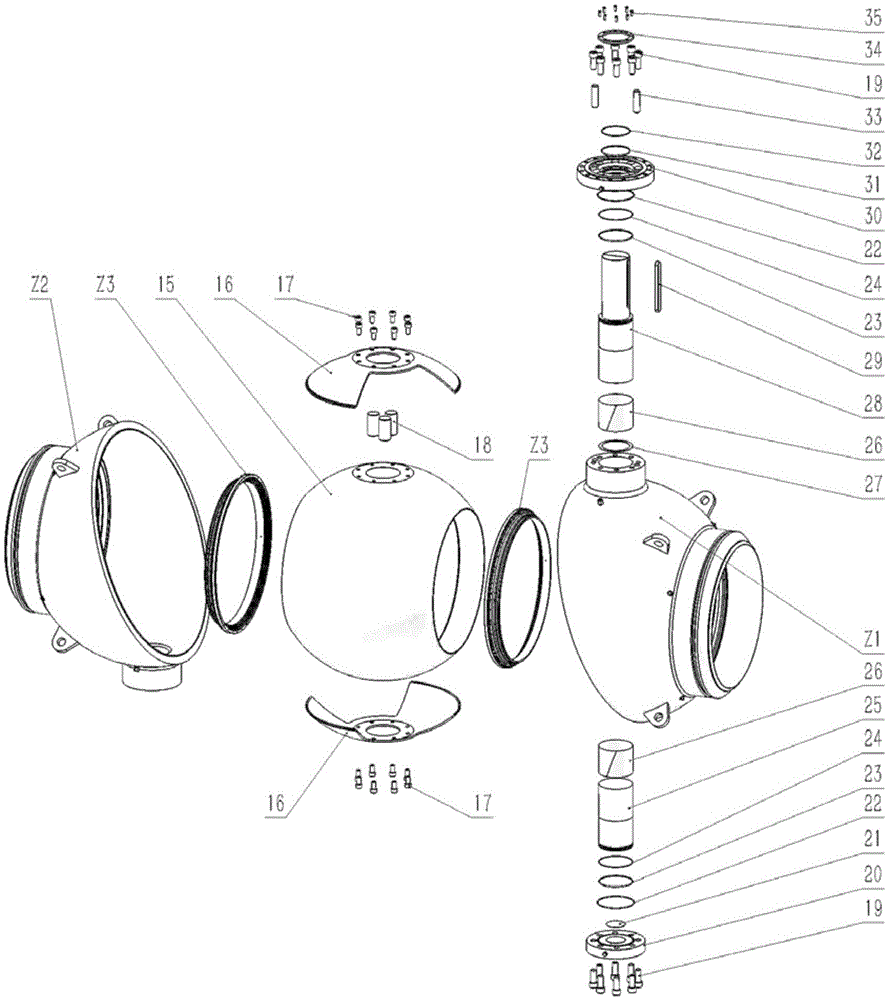

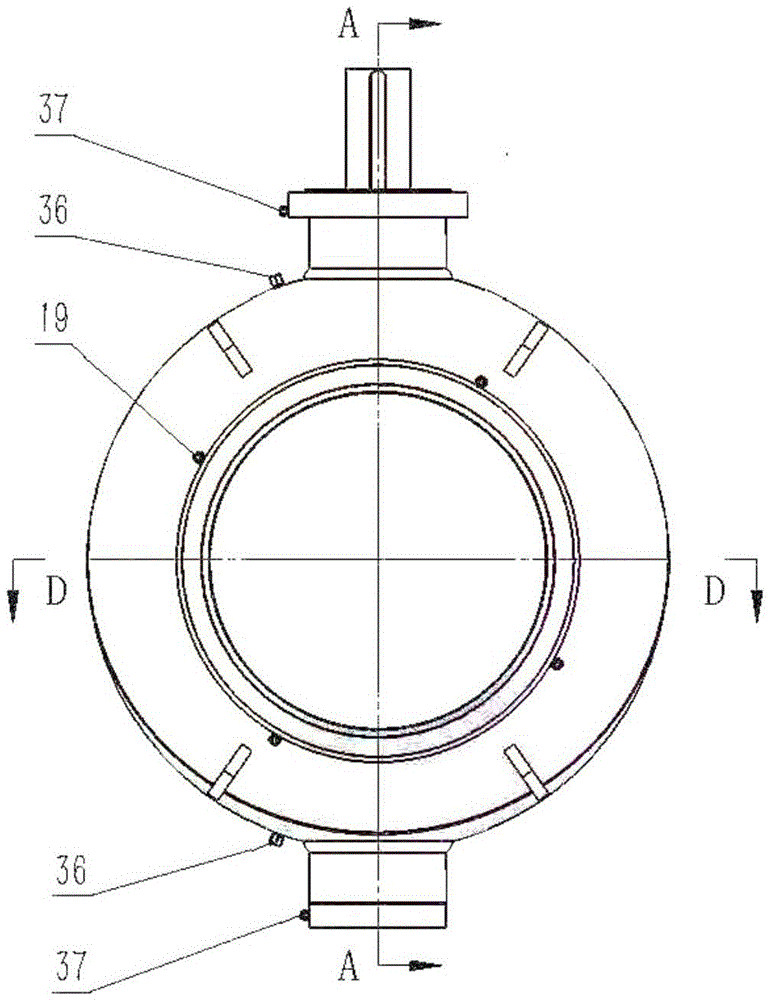

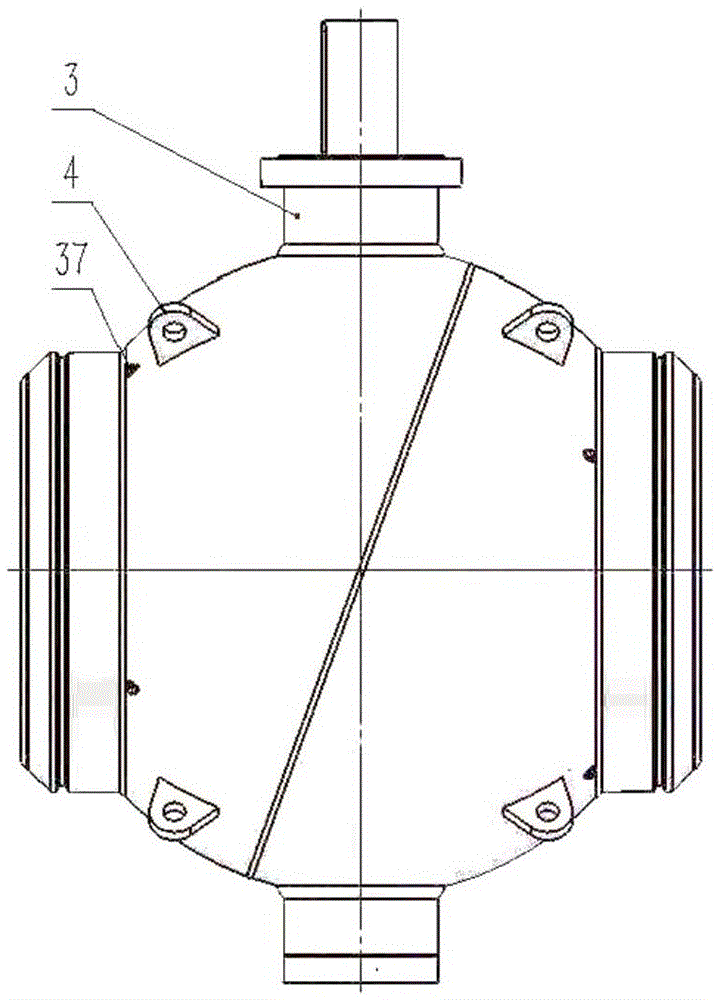

[0054] Such as Figure 1-7 As shown, it is a schematic diagram of the assembly of the spherical monoclinic welded seam fully welded ball valve without friction in the valve seat switching process of the present invention.

[0055] A spherical single-slope fully welded ball valve with no friction in the process of opening and closing of the ball and seat, mainly including: a right hemispherical valve body assembly Z1, a left hemispherical valve body assembly Z2, two valve seat assemblies Z3, a ball 15, two A valve seat support disc 16.

[0056] The right hemispherical valve body assembly Z1 and the left hemispherical valve body assembly Z2 each include a hemispherical shell 1, a connecting pipe 2 and a pivot sleeve 3; the inner wall of the passage of the connecting pipe 2 is provided with a valve seat assembly setting part; the pivot sleeve The central axis of 3 is vertically intersected with the channel axis of the connecting pipe 2; the ring surface of the butt welding groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com