Device for controlling temperature and humidity of large-scale electrostatic spinning environment

An environmental temperature and humidity, electrospinning technology, applied in heating and ventilation control systems, piping arrangements, heating methods, etc., can solve the problems of unadjustable and unstable electrospinning temperature and humidity, and achieve safe use, stable control, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

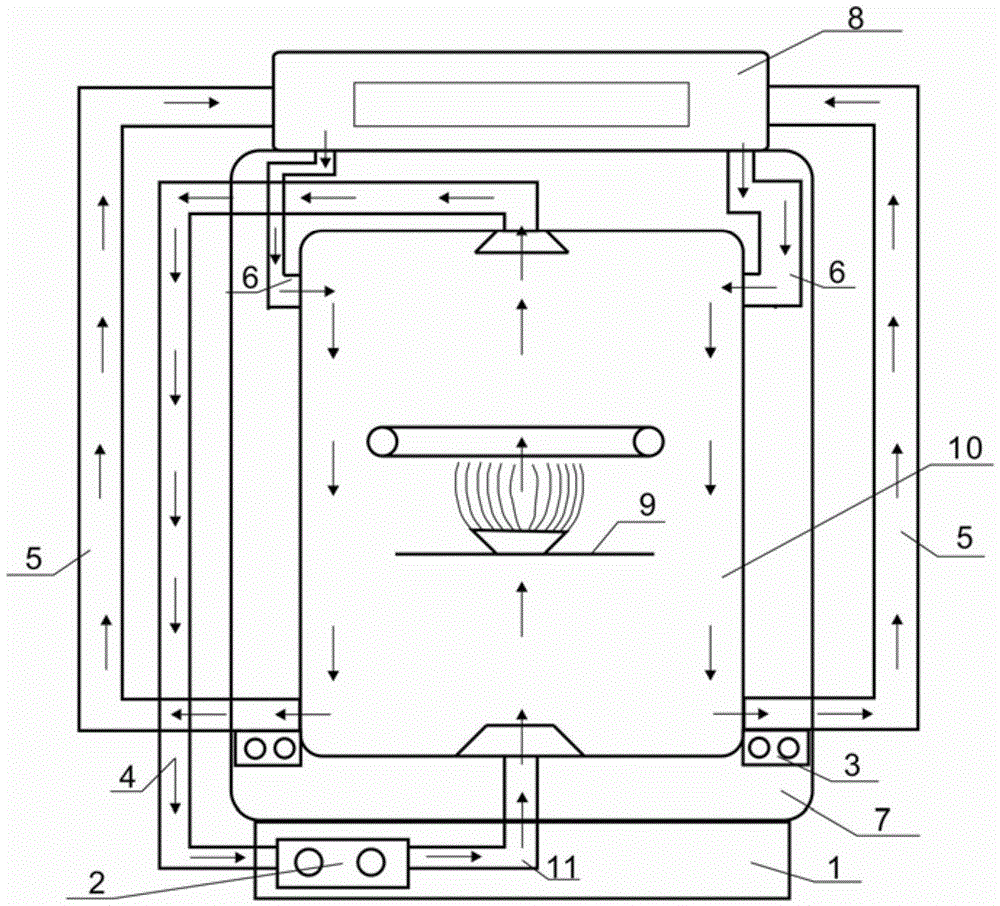

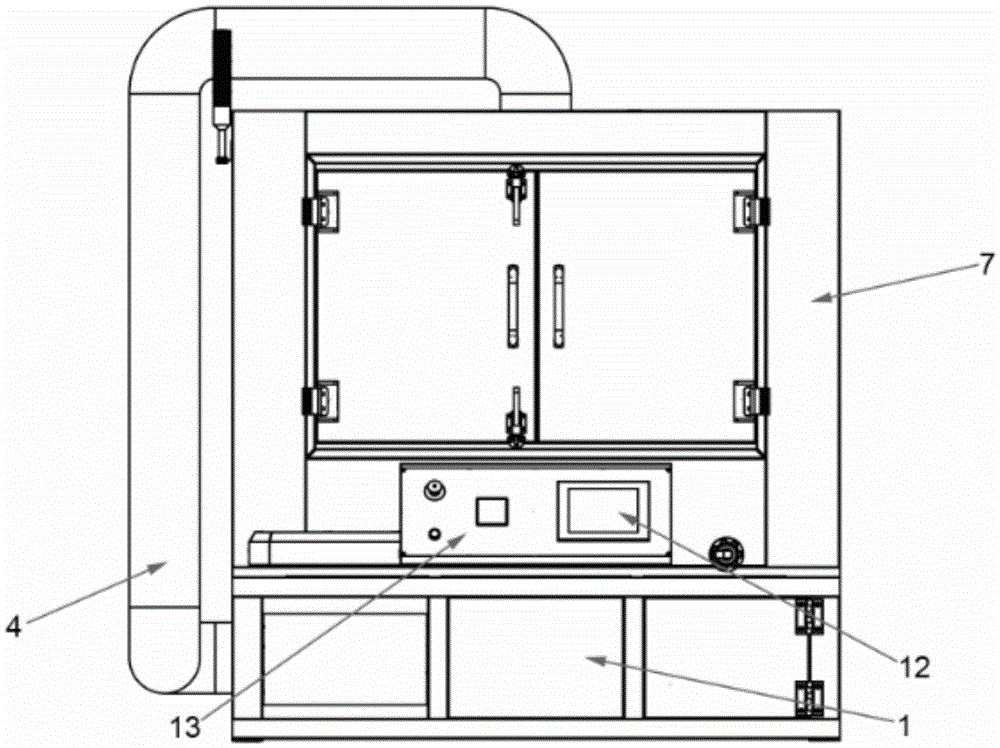

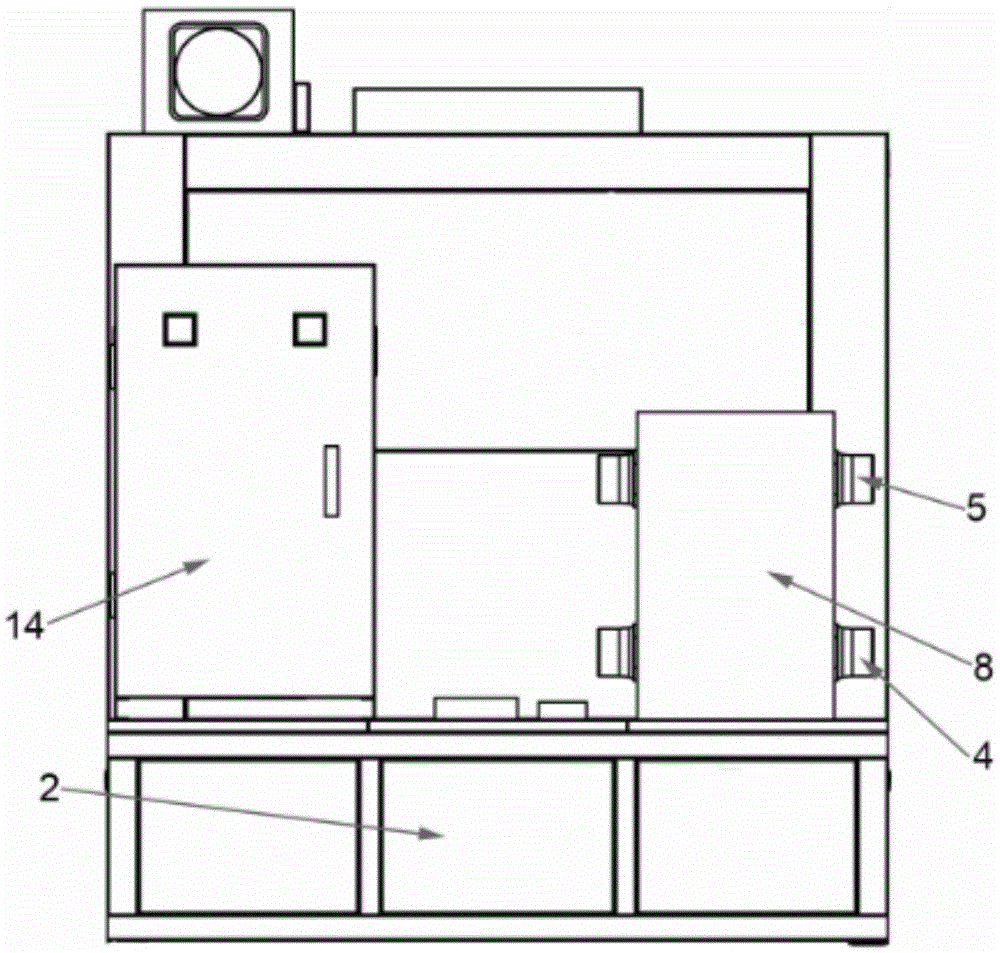

[0027] Such as Figure 1~3 As shown, a device for controlling the temperature and humidity of a large-scale electrospinning environment includes a base 1, an air conditioner 2, a heater 3, an equipment box shell 7 and a dehumidifier 8, wherein the equipment box shell 7 is installed on On the base 1, the inside of the equipment box shell 7 is provided with a working room 10, the described dehumidifier 8 and the power supply box 14 are installed on the base 1 at the rear end of the equipment box shell 7, and the return air outlet of the dehumidifier 8 One end of the dehumidifier return air duct 5 is connected, and the other end of the dehumidifier return air duct 5 is installed on the lower part of the side of the equipment box shell 7 and connected with the working room 10. The regeneration outlet of the dehumidifier 8 is connected to the dehumidifier One end of the regeneration air duct 6 is connected, and the other end of the regeneration air duct 6 of the dehumidifier is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com