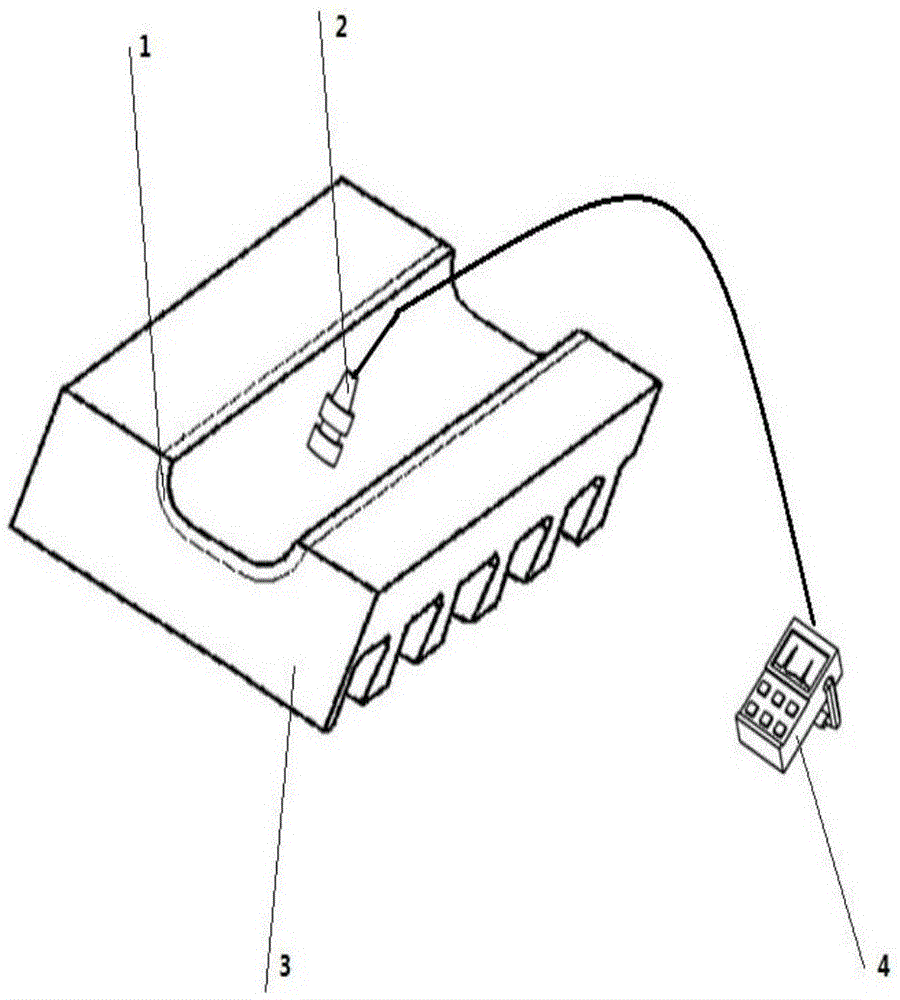

Detection method for melting effect between cast copper cooling wall body for blast furnace and cast-in cooling water pipe for blast furnace

A technology of cast copper cooling wall and cooling water pipe, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc. It can solve the problems of difficult detection and analysis, coarse grains, etc., and achieve accurate thickness measurement, uniform and fine structure, and stable echo Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The thickness of the rolled copper stepped block is tested ultrasonically. The measured ladder test block is taken from the rolled copper stave body. The step height of the step test block is set to 8mm, 10mm, 20mm, 30mm, 40mm, 60mm, and the width is 60mm. The physical size of the stepped block taken from the rolled copper stave body is shown in the figure image 3 As shown, the ultrasonic flaw detector used is Youlian PSUT-350B full-digital intelligent ultrasonic flaw detector, which uses a φ14mm straight crystal probe and a transmission frequency of 2.6MHz. Zero point correction and sound velocity determination are required before the actual measurement. In this example, the cubic standard thickness test block processed by sampling and processing the rolled copper stave body of 40mm×40mm×40mm is used for straight probe calibration and sound velocity measurement. After the measurement, the sound velocity of ultrasonic waves in the rolled copper stave is 4678m / s. Aft...

Embodiment 2

[0043] The thickness of the cast copper step block is tested by ultrasonic. The measured ladder test block is taken from the cast copper stave body. The height of the steps is set to 8mm, 10mm, 20mm, 30mm, 40mm, 60mm, and the width is 60mm. The physical size of the stepped block taken from the cast copper stave body is shown in the figure Figure 4 shown. The ultrasonic flaw detector used is Youlian PSUT-350B all-digital intelligent ultrasonic flaw detector, which uses a φ14mm straight crystal probe and a transmission frequency of 2.6MHz. Before the actual measurement, it is necessary to use the 40mm×40mm×40mm cast copper stave body to sample and process the cubic standard thickness test block for zero point correction and sound velocity measurement. The engine oil is used as the coupling agent. The cube is taken from the same cast copper stave as the stepped test block. ontology. After measurement, the sound velocity of ultrasonic waves in the cast copper cooling stave is...

Embodiment 3

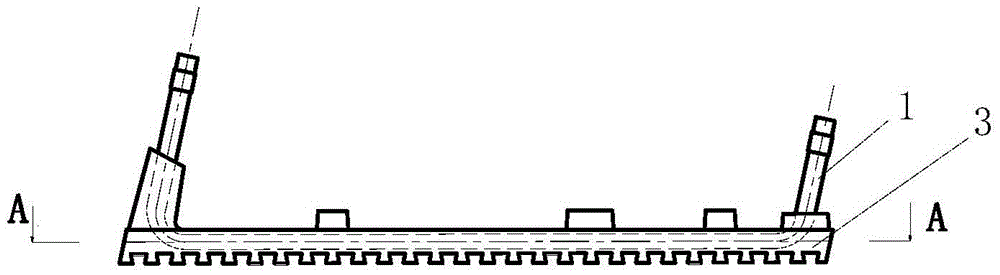

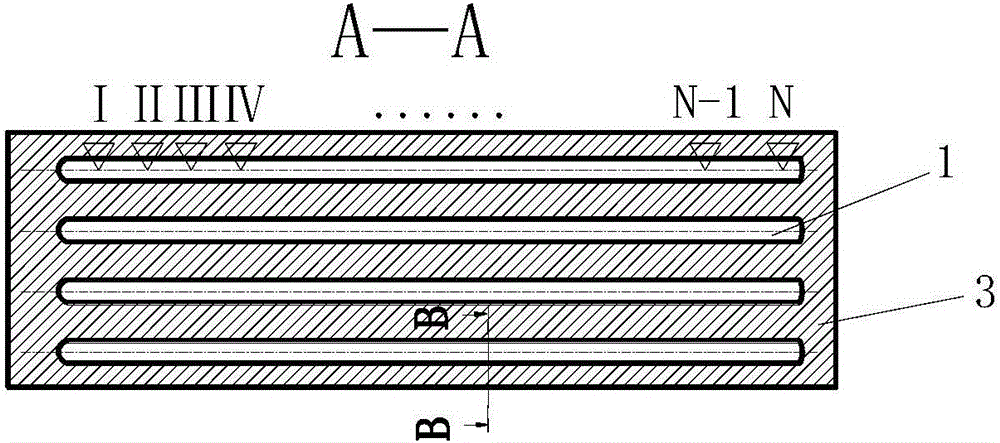

[0049] Detection of the interface fusion effect between the cast copper stave body and the cast cooling water pipe. The lower part (including the hot surface) of the solid block of the cast copper stave is intercepted, and its front view, top view and schematic diagram of the test point location are as follows Figure 5a , Figure 5b shown. The positions of the test points selected according to the ultrasonic wave are different (see Figure 5b ), the method provided by the invention can realize preliminary determination and quantitative analysis of the fusion rate of the metallurgical bonding between the embedded copper pipe in the cast copper stave and the cast copper stave body.

[0050] Preliminary judgment of fusion effect: directly detect the thickness of the embedded pipe from the hot surface of the cast copper stave, that is, Figure 5a Middle A direction carries out ultrasonic thickness detection. The advantage of adopting this scheme is that the selected point mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com