Incineration furnace for pasty products, in particular sludge from purifying stations

A sludge incineration and incinerator technology, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of people not quickly observing, permanent clogging of sludge, clogging of injection nozzles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

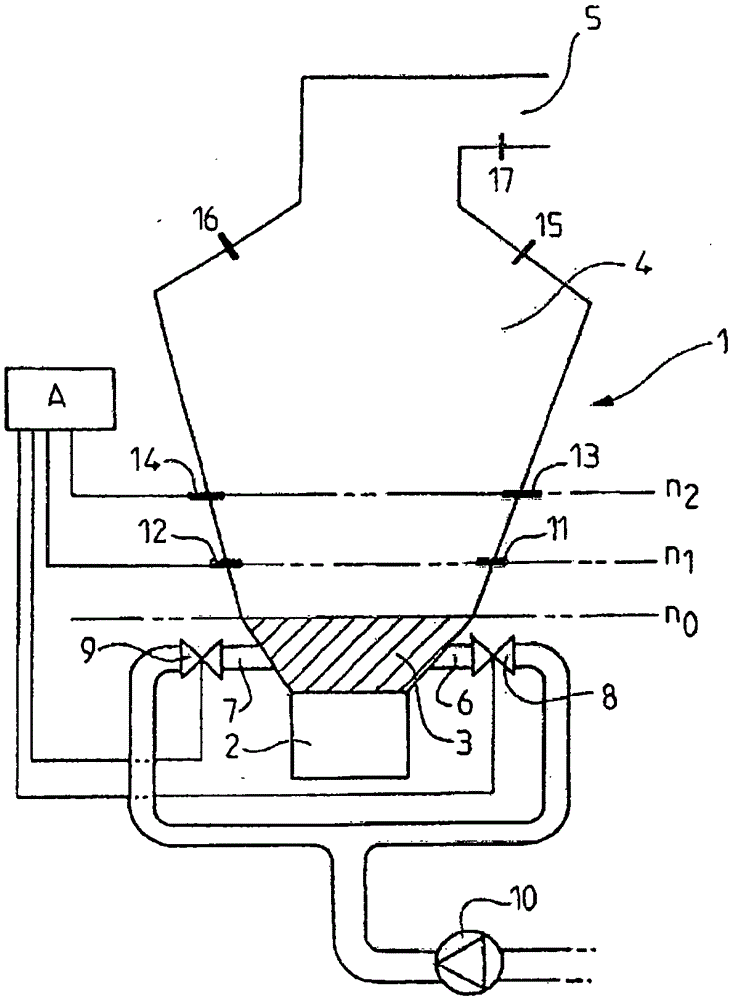

[0025] from figure 1 Incinerators for pasty products, especially sludge from sewage treatment plants, fluidized beds with granular materials, especially sand, can be seen.

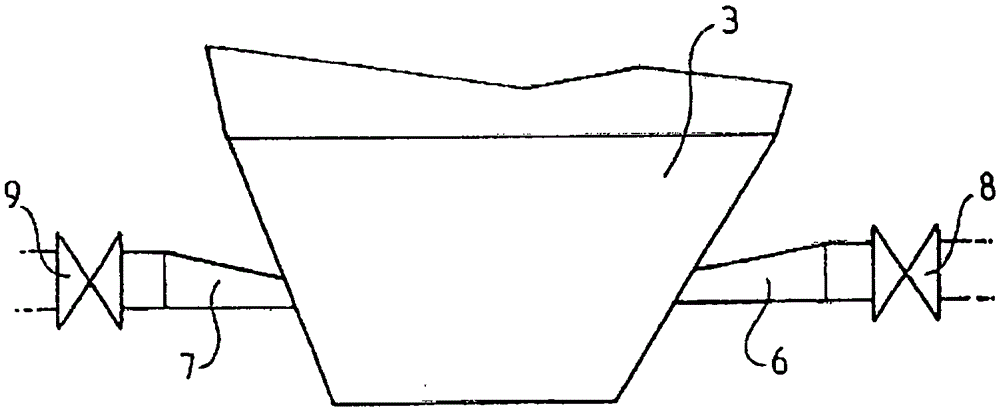

[0026] The incinerator 1 has at its bottom a wind box 2 on which a sand bed 3 is placed. The bellows 2 are connected to the delivery end of a blower, not shown, for blowing air through the bed 3 . Pipelines, not shown, make it possible to pass air from the air box to the sand bed 3 to ensure fluidization of the sand. Above the sand bed there is an afterburner zone 4 with an opening above and a flue gas output duct 5 .

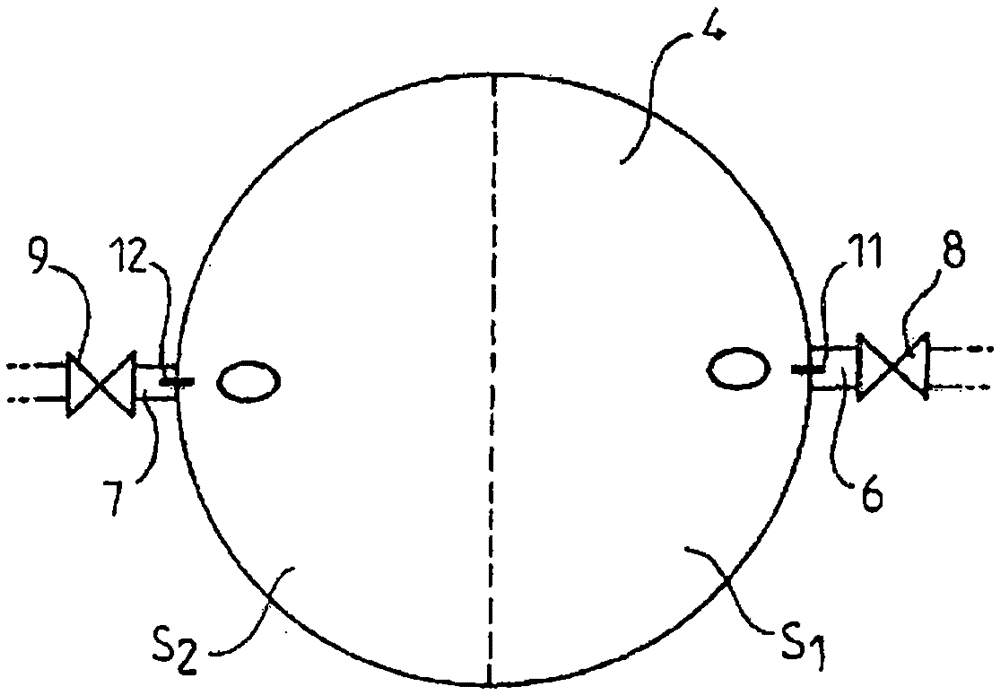

[0027] Two injection nozzles 6 and 7 are located on either side of the sand bed 3 , preferably diametrically opposite, enabling the injection of the sludge to be incinerated into the sand bed 3 . The feed to the nozzles 6 and 7 is regulated by opening and closing the respective valves 8 and 9, preferably solenoid valves. The feeding of the pressurized nozzles takes place by means of pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com