A different temperature rolling method for preparing stainless steel and carbon steel clad plate

A technology of isothermal rolling and stainless steel, which is applied in the field of isothermal rolling for preparing stainless steel and carbon steel clad plates, can solve the problems of high bonding strength, large stress, uncoordinated deformation of stainless steel and carbon steel, and reduce the deformation The effect of poor resistance, reduction of residual stress, and coordination of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

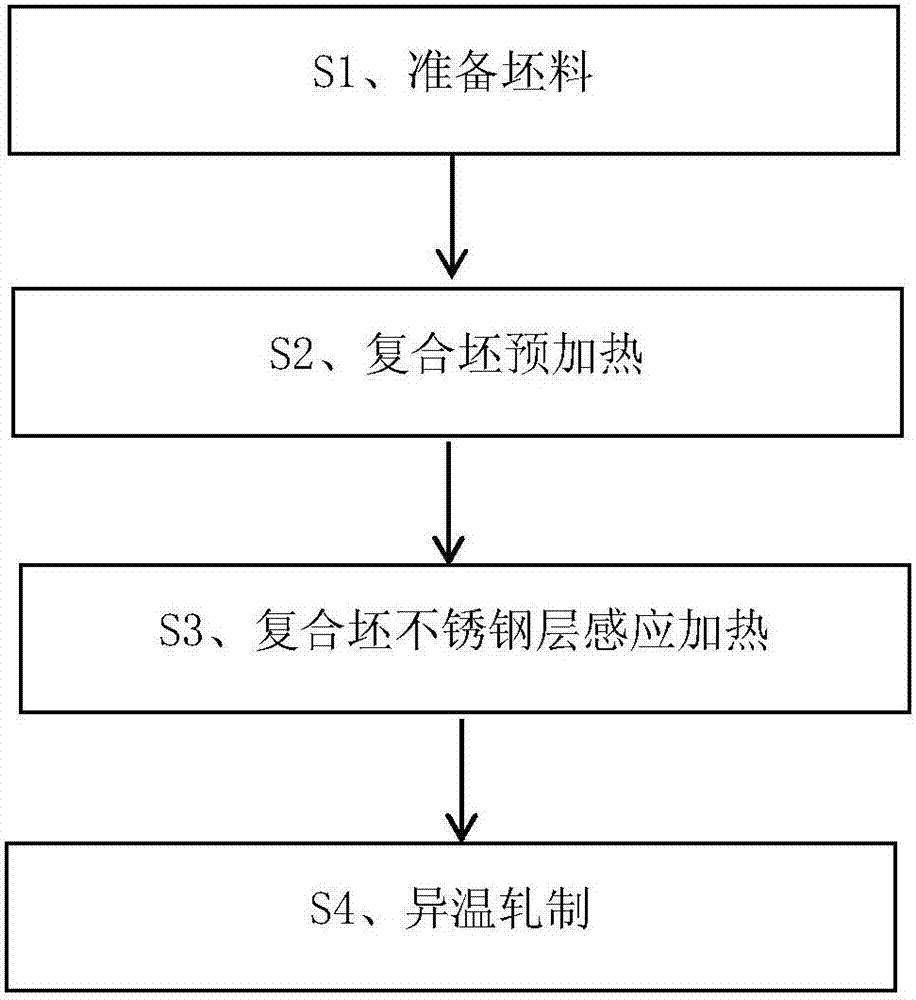

[0036] Preparation of single-sided stainless steel and carbon steel composite panels

[0037] S1. Blank preparation: select a piece of stainless steel with a length of 500mm, a width of 100mm, and a thickness of 7mm, and a piece of carbon steel with a length of 500mm, a width of 100mm, and a thickness of 20mm. The surface to be bonded of the stainless steel billet and the surface to be bonded of the carbon steel billet are stacked facing each other, and the edges are sealed and welded with a vacuum electron beam and vacuumized to obtain a single-sided stainless steel composite billet;

[0038] S2. Composite billet preheating: use a high-temperature box-type resistance furnace to heat the composite billet obtained in S1 to 1000°C as a whole, and keep it warm for 2 hours;

[0039] S3. Composite billet induction heating: use an induction heater to reheat the stainless steel layer of the composite billet preheated in S2, the induction heating current is 4200A, the frequency is 2.5...

Embodiment 2

[0042] Preparation of double-sided stainless steel and carbon steel composite panels

[0043]S1. Blank preparation: Select two pieces of stainless steel with a length of 500mm, a width of 100mm, and a thickness of 3mm and a piece of carbon steel with a length of 500mm, a width of 100mm, and a thickness of 10mm. Use a wire brush to remove the oxide layer on the surface to be bonded between the stainless steel and carbon steel and clean it with acetone and alcohol. , stacking the surface to be bonded of the stainless steel blank and the surface to be bonded of the carbon steel blank facing each other, sealing and welding the edges with a vacuum electron beam and vacuumizing to obtain a double-sided stainless steel composite blank;

[0044] S2. Composite billet preheating: use a high-temperature box-type resistance furnace to heat the composite billet obtained in S1 to 1250°C as a whole, and keep it warm for 0.5h;

[0045] S3. Composite billet induction heating: Use the induction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com