Method for preparing steel-aluminum composite plate by using electromagnetic induction heating and rolling process

An electromagnetic induction heating and induction heating technology, which is applied in metal processing equipment, manufacturing tools, metal rolling, etc., can solve the problems affecting the reprocessing performance of steel-aluminum composite panels, low bonding strength of composite panels, and difficulty in cold rolling and lamination. Achieve the effect of reducing the critical composite deformation rate, deformation coordination, and high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

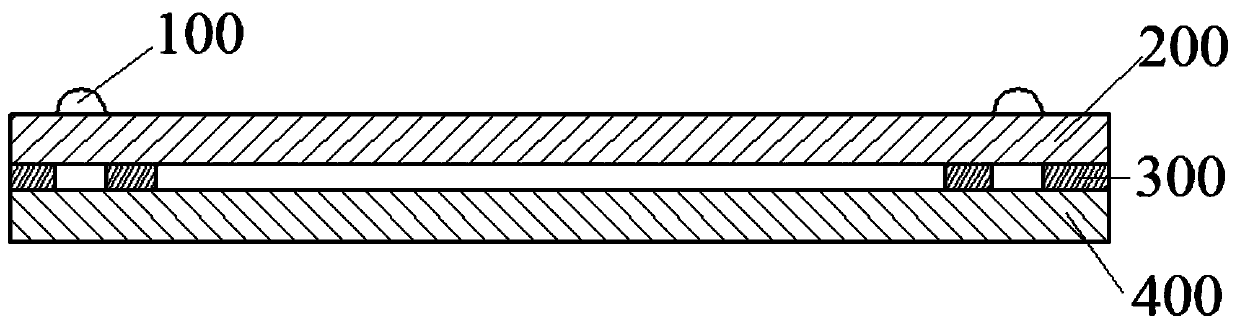

[0043] (1) Take Q235 steel plate and 6061 aluminum alloy plate with the same length, width, and thickness of 120mm, 60mm, and 2mm respectively. The steel plate is annealed at 800°C for 2 hours and then air-cooled. The aluminum alloy plate is annealed at 530°C for 2 hours and then air-cooled. , and then use a grinder equipped with No. 180 diamond sandpaper to clean the oxide layer and grease and other impurities on the composite surface of the steel plate and aluminum plate, and repeatedly clean it in an ultrasonic cleaning instrument equipped with acetone and alcohol, and finally dry it The machine is immediately dry and ready for use;

[0044] (2) After aligning and superimposing the above-mentioned steel plates and aluminum plates, place 1mm spacers around the plates to leave a 1mm gap between the plates, and then use aluminum rivets to rivet the plates to fix the four corners;

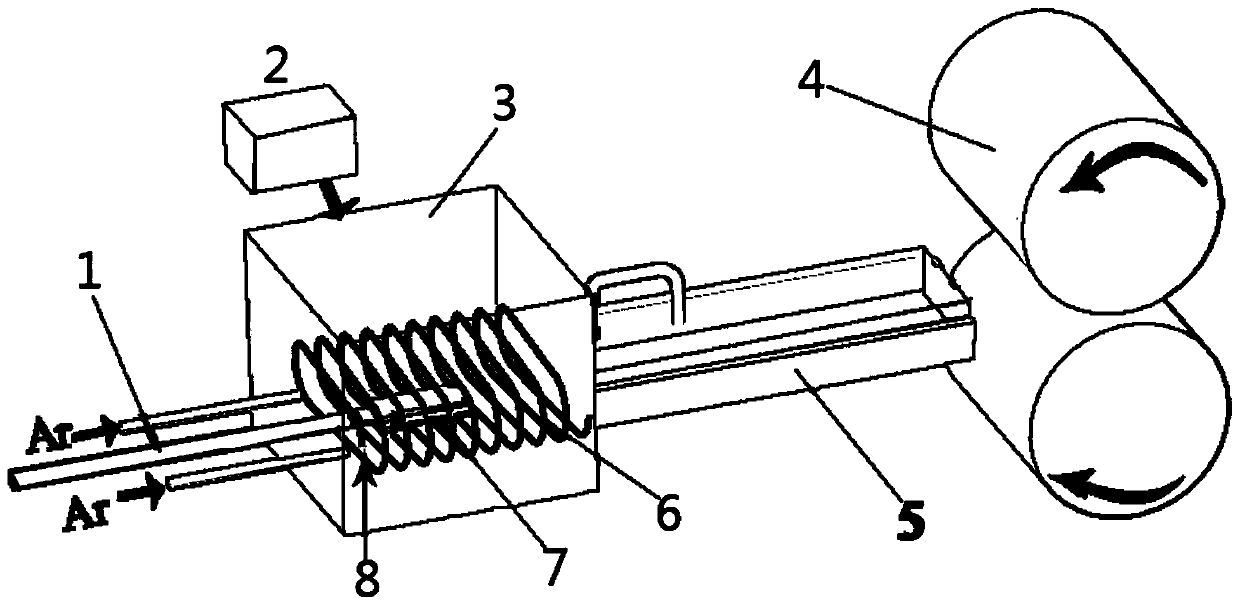

[0045] (3) Put the assembled symmetrical slab into the induction heating furnace, and pass the i...

Embodiment 2

[0051] (1) Take Q235 steel plates with length, width, and thickness of 120mm, 60mm, and 3mm respectively, and 6061 aluminum alloy plates with 120mm, 60mm, and 1mm respectively. Anneal the steel plates at 800°C for 2 hours and then air-cool them. Anneal for 2 hours and then air-cool, then use a grinding machine equipped with No. 180 diamond sandpaper to clean the oxide layer and grease and other impurities on the surface of the steel plate and aluminum plate to be combined, and clean it repeatedly in an ultrasonic cleaning instrument equipped with acetone and alcohol. Finally, use the dryer to dry immediately for later use;

[0052] (2) After aligning and stacking the above-mentioned steel plates and aluminum plates, place 1.5mm gaskets around the plates to leave a 1.5mm gap between the plates, and then use aluminum rivets to rivet the plates to fix the four corners;

[0053] (3) Put the assembled symmetrical slab into the induction heating furnace, and pass the inert gas into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com