Automatic stud welding device applicable to T-shape welding studs

An automatic welding and stud welding technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of operator safety hazards, low yield, low productivity, etc., and achieve stable welding quality, safe use, and installation. and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

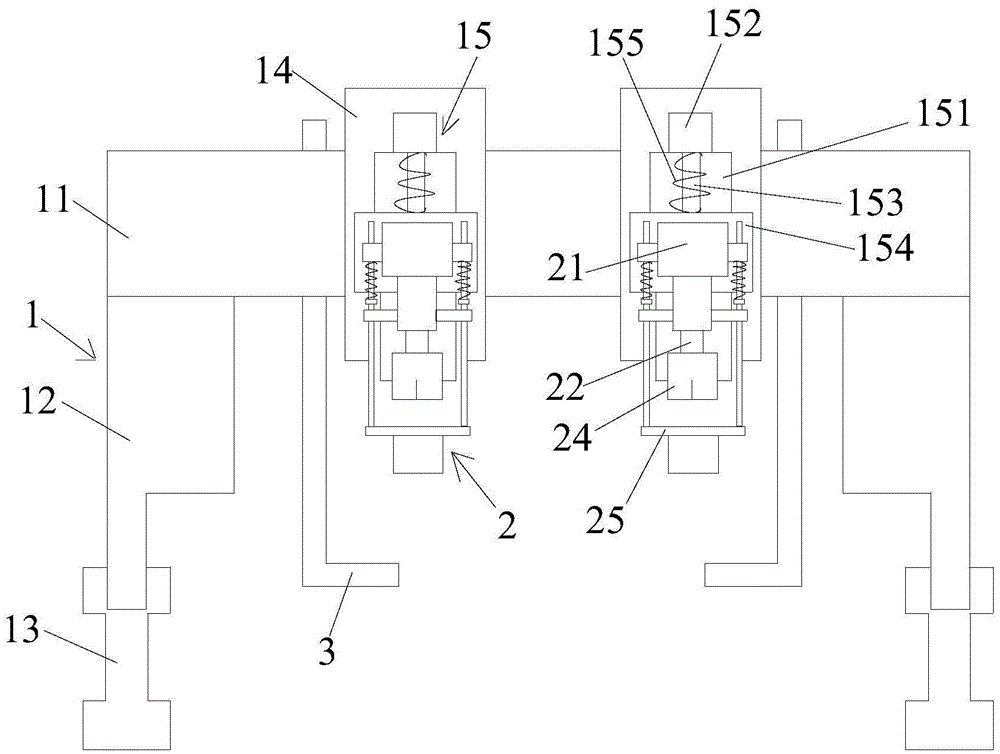

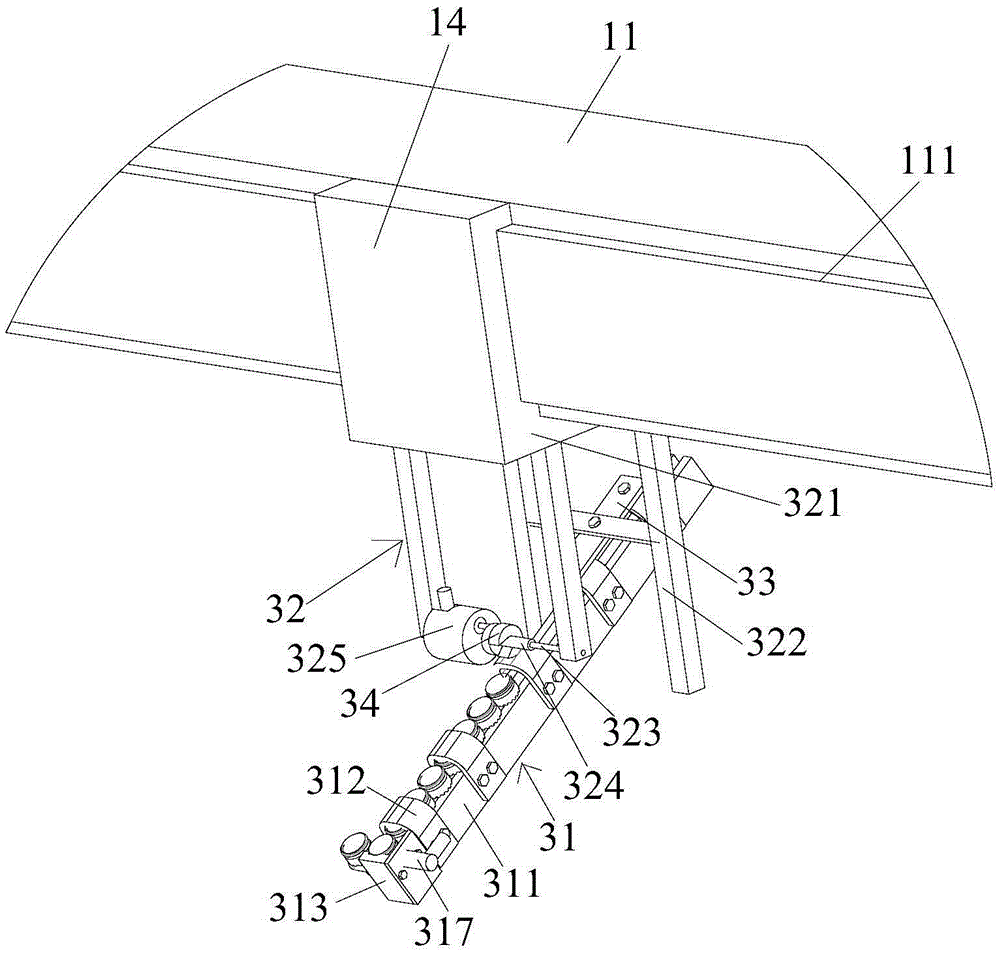

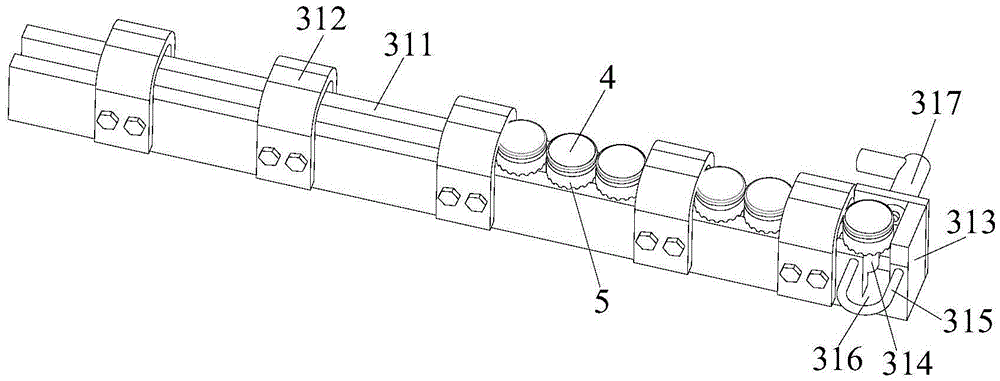

[0036] combine figure 1 and figure 2As shown: a device suitable for automatic stud welding of T-shaped welding studs provided by the present invention includes a three-axis motion platform 1, several automatic welding guns 2 and several automatic feeding mechanisms 4, and each automatic welding gun 2 is equipped with an automatic feeding mechanism 4. The three-axis motion platform 1 includes a crossbeam 11, legs 12, ground rails 13, a horizontal motion slider 14 and a three-axis motion drive mechanism (not shown in the figure), and the crossbeam 11 is fixed on the legs 12 , the legs 12 are slidably connected to the corresponding ground rail 13, the horizontal movement slider 14 is slidably connected to the slide rail 111 provided on the beam 11, and a lifting movement mechanism 15 is fixed on the horizontal movement slider 14, The lifting motion mechanism 15 includes a fixed base A151, a lifting motor 152, a lifting shaft 153 and a mounting base 154. A spring A155 is set on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com