Welding device for single row type copper pipe component

A technology for welding devices and copper tubes, which is applied in the direction of providing/removing shielding gas devices, welding equipment, welding accessories, etc., which can solve the problems of inconvenient welding shielding gas, low work efficiency, and poor welding quality, so as to improve welding efficiency and quality, guaranteed production capacity, and convenient welding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, the present invention is described in further detail:

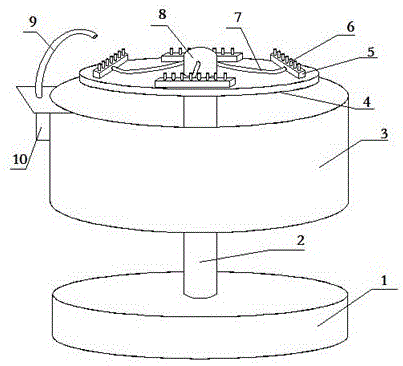

[0012] like figure 1 As shown, a single-row copper pipe assembly welding device of the present invention includes a rotating disk 4 and a supporting column 2, the center of the rotating disk 4 is rotationally connected with the top of the supporting column 2, and the top of the rotating disk 4 is provided with an open A cylindrical water tank 3, the diameter of the water tank 3 is greater than the diameter of the rotating disk 4, the middle part of the support column 2 runs through the water tank 3 along the central axis of the water tank 3 and is sealed and fixedly connected with the bottom of the water tank 3, and the bottom of the support column 2 is connected to the base 1; The support column 2 is pierced with a welding shielding gas inlet pipe, and the center of the top of the rotating disk 4 is provided with a gas distribution column 8, and the gas distribution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com