Tank, system and method for manufacturing three-dimensional body

A technology of three-dimensional objects and cylinders, applied in the direction of additive processing, etc., can solve the problems of reducing productivity, difficulty in obtaining thin layer dimensional accuracy with uniform layer thickness, and increasing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to allow those skilled in the art to better understand and realize the technical solution of the present invention, further detailed description will be given below in conjunction with the accompanying drawings and specific embodiments.

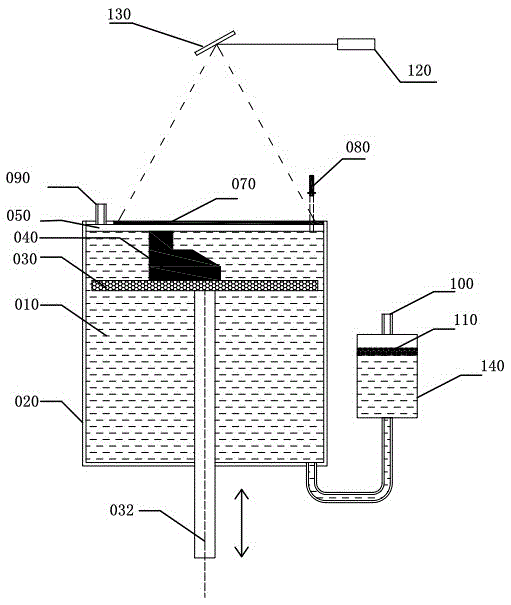

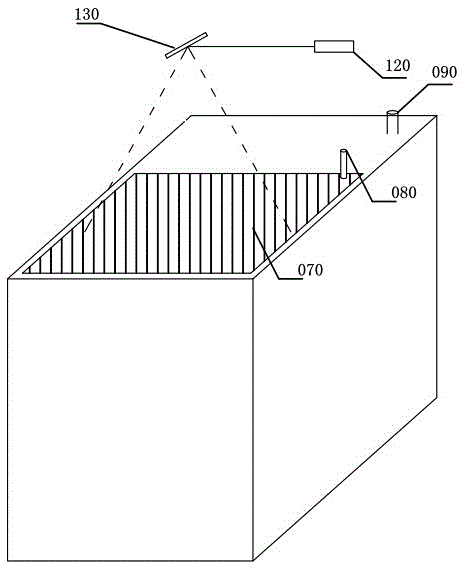

[0021] figure 1 is a structural schematic diagram of the system for manufacturing three-dimensional objects according to the present invention, figure 2 yes figure 1 Side view of the cylinder block. Such as figure 1 figure 2 As shown, the system for manufacturing three-dimensional objects includes a laser 120 , a tank and a support platform 030 , wherein the tank includes a cylinder 020 and a resin replenishment cylinder 140 . The cylinder body 020 is filled with liquid resin material 010, and the top is embedded with a light-transmitting plate 070 corresponding to the laser 120. The light beam generated by the laser 120 can pass through the deflection mirror 130 and enter the cylinder body 020 through the light-transmit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com