A kind of asphalt polishing disk and preparation method thereof

A polishing disc and asphalt technology, which is applied in the direction of grinding/polishing equipment, polishing composition containing abrasives, manufacturing tools, etc., can solve the problems affecting the processing quality such as the smoothness of optical components, and improve surface flatness and polishing accuracy , improve the elastic modulus performance, and the effect of fast polishing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

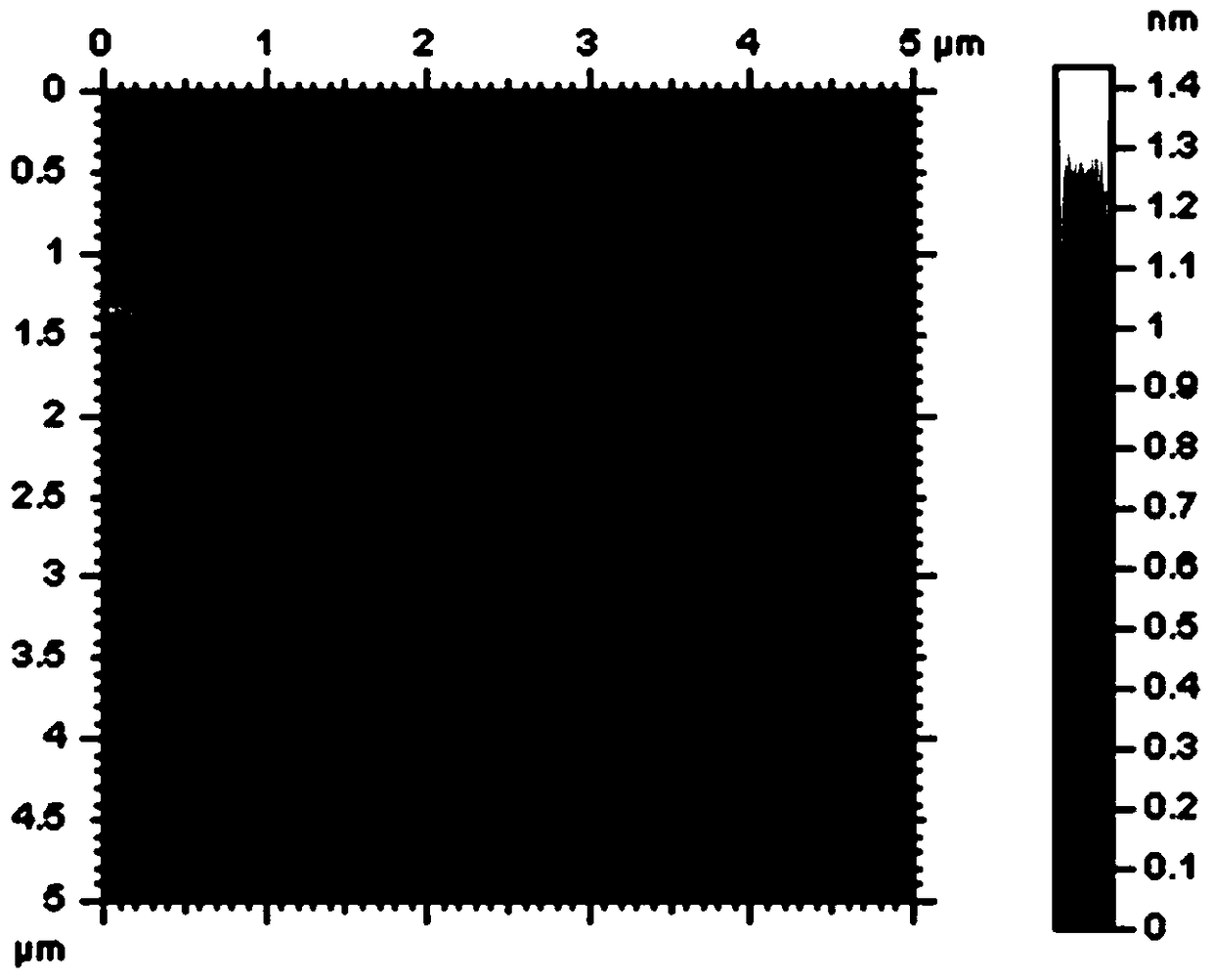

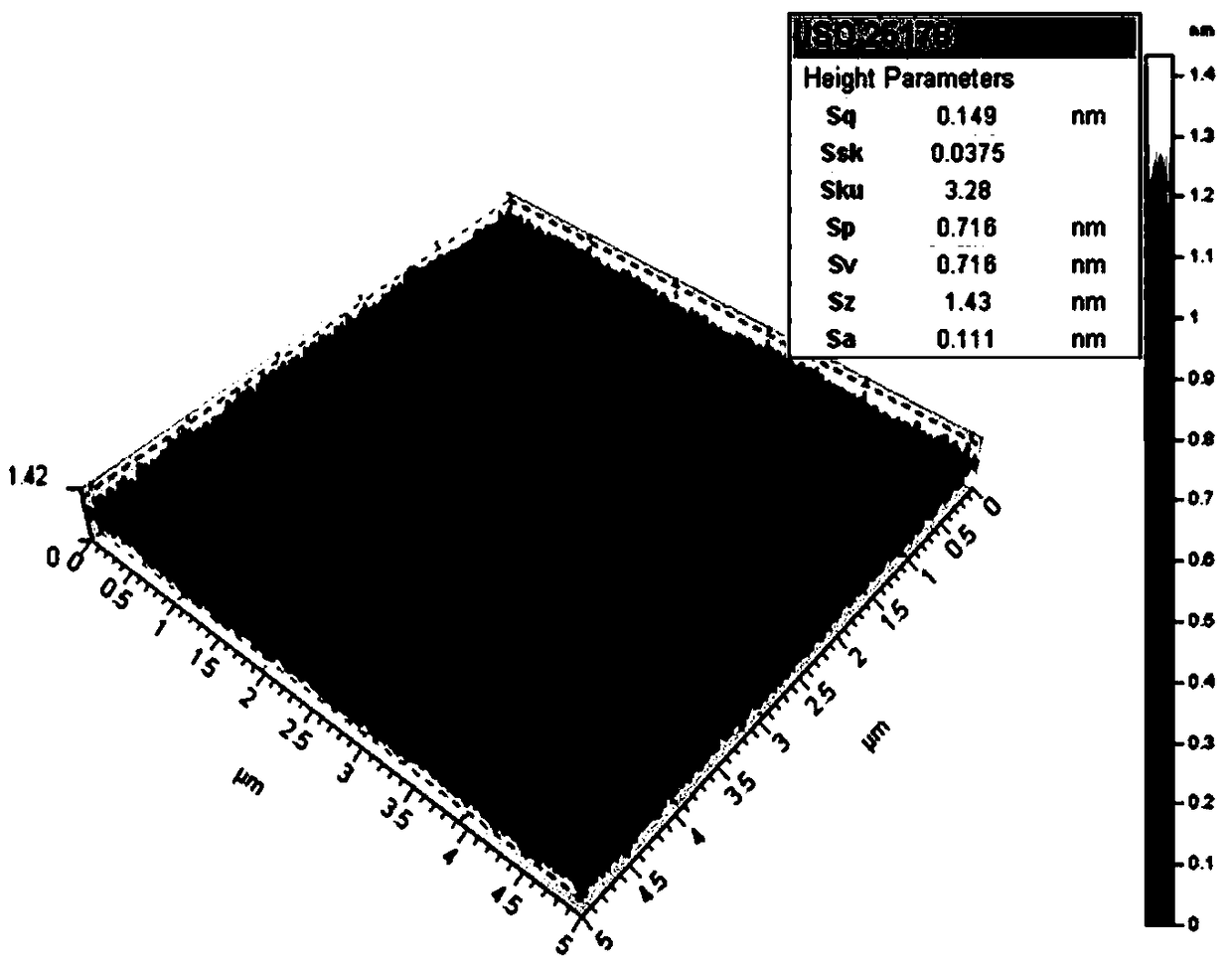

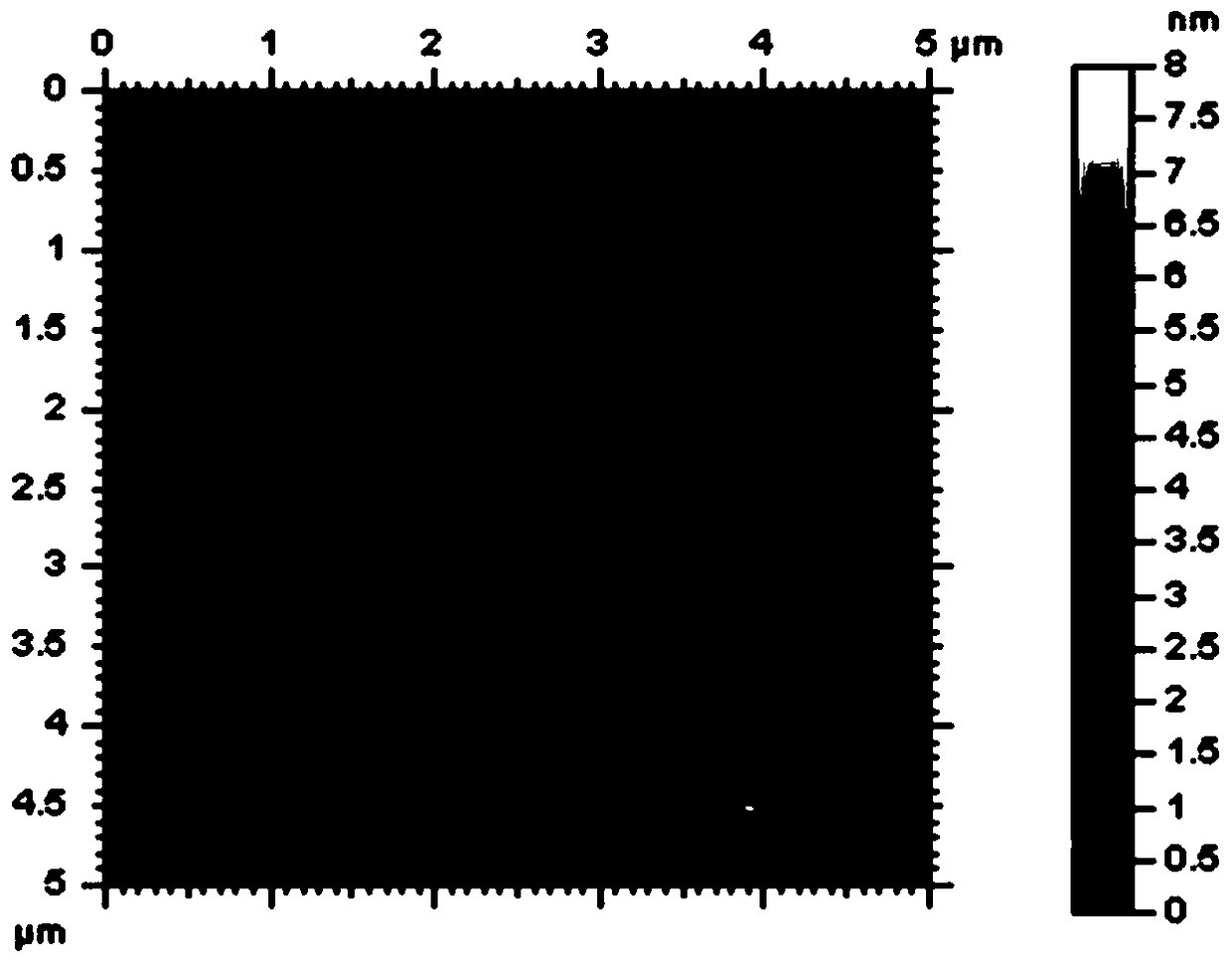

Image

Examples

Embodiment 1

[0037] The present embodiment provides a kind of asphalt polishing disk, and it adopts following raw material to prepare:

[0038] Polished asphalt (U.S. Global Optics Co., Ltd. provides, 82#), 80 parts by weight;

[0039] Paraffin (Sinopharm Group Chemical Reagent Co., Ltd., section paraffin 69019562), 5 parts by weight;

[0040] Polycrystalline diamond abrasive (provided by Beijing Guoruisheng Technology Co., Ltd., PCD0.1-3), 5 parts by weight;

[0041] White carbon black (particle size is 50nm, Degussa A380), 5 parts by weight;

[0042] Nylon 66 (the fineness is 1.2D, the length is 0.5mm, U.S. DuPont 408HS), 5 parts by weight.

[0043] Further, the asphalt polishing disc is prepared by the following method, and the specific steps include:

[0044] (1) Clean the surface of the loading tray to ensure that it is dry and dust-free, and wrap a circle of double-sided adhesive around the surrounding of the loading tray, uncover the double-sided adhesive, and stick a circle of P...

Embodiment 2

[0050] The present embodiment provides a kind of asphalt polishing disk, and it adopts following raw material to prepare:

[0051] Polished asphalt (U.S. Global Optics Co., Ltd. provides, 55#), 90 parts by weight;

[0052] Bonding wax (Tianjin Nuobang Technology Co., Ltd. NP-T70), 2 parts by weight;

[0053] Single crystal diamond abrasive (provided by Beijing Guoruisheng Technology Co., Ltd., the product model is D0.5), 3 parts by weight;

[0054] White carbon black (particle size is 100nm, Nalco 2329PLUS), 3 parts by weight;

[0055] Nylon 612 (the fineness is 3D, the length is 0.4mm, U.S. DuPont 350PHS), 2 parts by weight.

[0056] Further, the asphalt polishing disc is prepared by the following method, and the specific steps include:

[0057] (1) Clean the surface of the loading tray to ensure that it is dry and dust-free, and wrap a circle of double-sided adhesive around the surrounding of the loading tray, uncover the double-sided adhesive, and stick a circle of kraft...

Embodiment 3

[0062] The present embodiment provides a kind of asphalt polishing disk, and it adopts following raw material to prepare:

[0063] Polished asphalt (U.S. Global Optics Co., Ltd. provides, 91#), 95 parts by weight;

[0064] Wood wax (Hefei Zhenxin Cleaning Equipment Co., Ltd. DPD01), 2 parts by weight;

[0065] White carbon black (particle size is 30nm, Degussa A200), 2 parts by weight;

[0066] Nylon 6 (denier is 0.5D, length is 0.1mm, U.S. DuPont 73G30L), 1 part by weight.

[0067] Further, the asphalt polishing disc is prepared by the following method, and the specific steps include:

[0068] (1) Clean the surface of the loading tray to ensure that it is dry and dust-free, and wrap a circle of double-sided adhesive around the surrounding of the loading tray, uncover the double-sided adhesive, and stick a circle of kraft paper;

[0069] (2) Heat the 91# polished asphalt at a temperature of 90° C. After it melts, add the wax, white carbon black and fluff in the above parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com