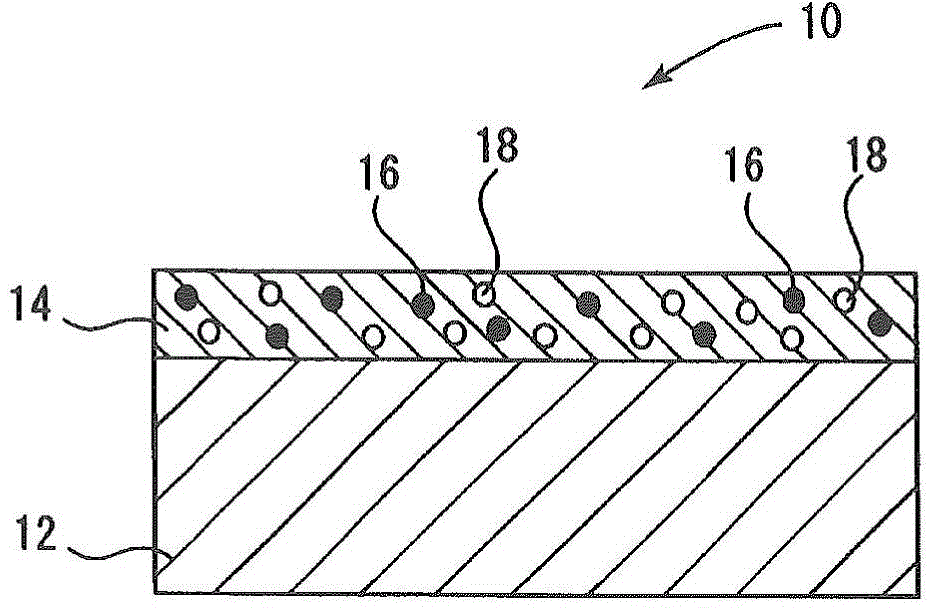

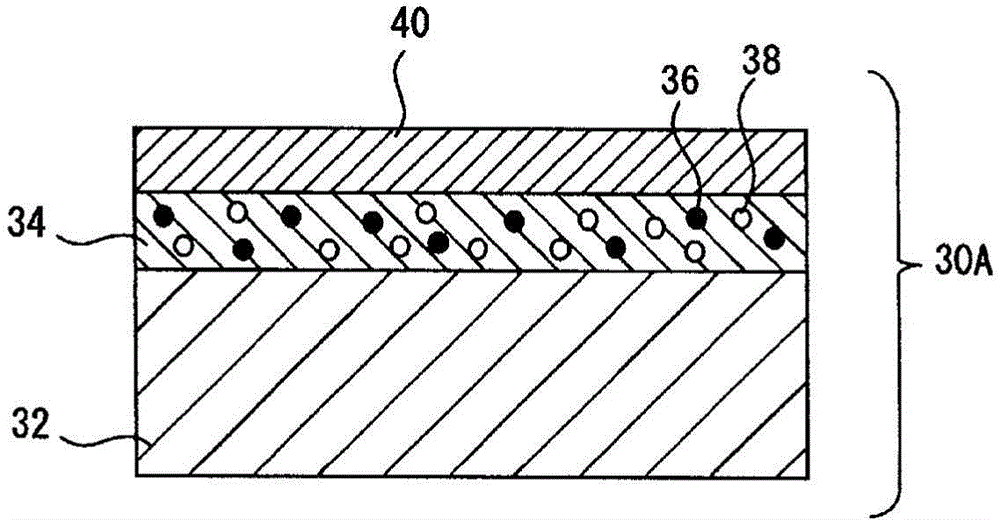

Silica glass member for wavelength conversion, and production method therefor

A technology of quartz glass and wavelength conversion, which is applied to chemical instruments and methods, optical components, electrical components, etc., and can solve problems such as functional degradation, surface part strength degradation, and tiny particles scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

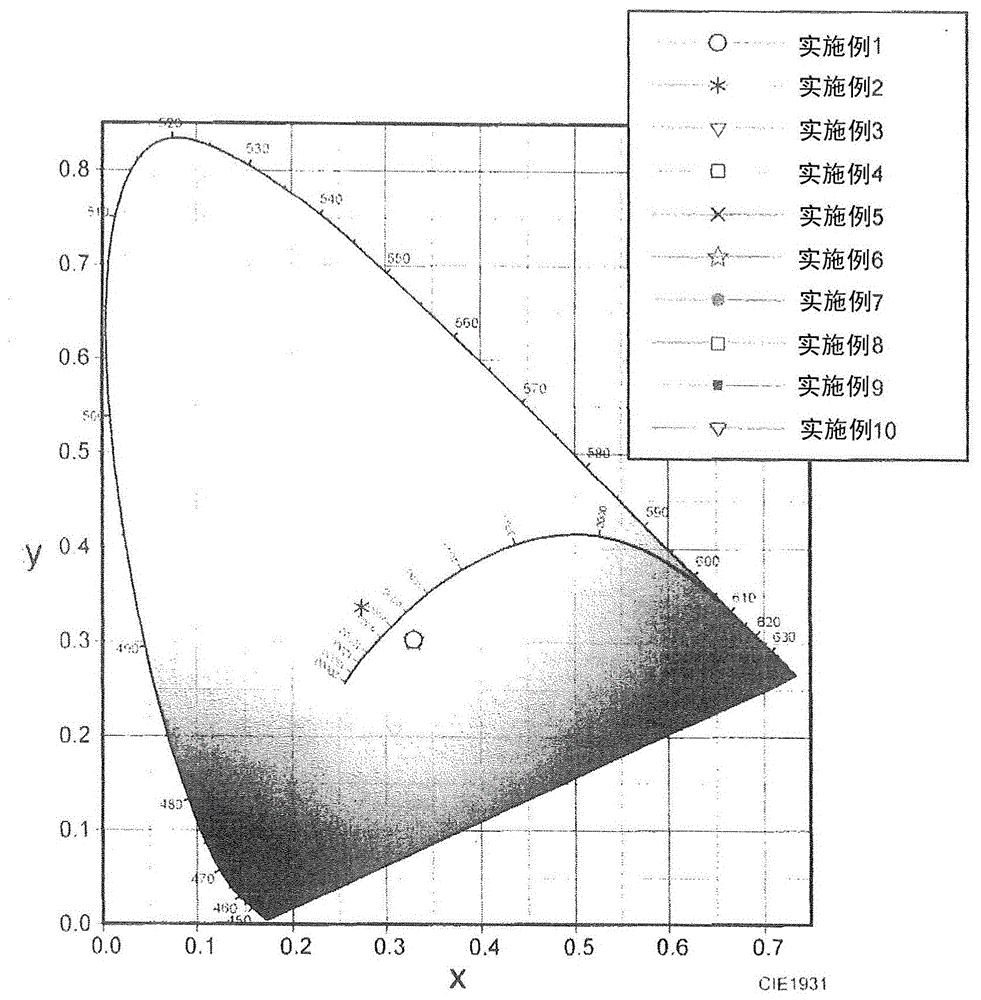

Embodiment 1

[0221] In a 500ml zirconia container, put 5g spherical deep ultraviolet light excitation phosphor (manufactured by U-VIX Co., Ltd., trade name: QKL65E / S-C1, average particle size 30μm (measurement device: microtrac MT3000 manufactured by Nikkiso Co., Ltd.) ), 10g 2-methoxyethanol (viscosity at 20℃ is 1.71mPa·s, at 20℃ vapor pressure is 0.83kP), 30g zirconia ball (diameter 5mm), 15g small zirconia ball (diameter 0.3mm), Six sets were performed at 250 rpm for 30 minutes, and they were mixed with a planetary ball mill to obtain a phosphor dispersion. After that, the 2-methoxyethanol was evaporated in the air in a dry oven at 100°C for 5 hours to make the pulverized phosphor-1 (lumps, bulk density 0.6g / cm) with a particle size of 1-10μm 3 , The average particle size is 5μm, the minimum particle size is 1μm, and the maximum particle size is 10μm) by drying.

[0222] Next, in TRYMAILE ANN120 (catalyst-free polysilazane 20% by mass dibutyl ether solution, manufactured by Sanwa Chemical ...

Embodiment 2

[0227] Except for using the following crushed phosphor-2 instead of the crushed phosphor-1 used in Example 1, the quartz glass member for wavelength conversion of Example 2 was produced in the same manner (the film thickness is 15μm, the light transmittance near 470nm is 4% , The residual NH group concentration is below 100ppm).

[0228] In the adjustment of the above-mentioned pulverized phosphor-1, a near-ultraviolet light excitation phosphor (trade name: UVW365, manufactured by U-VIX Co., Ltd.) was used instead of the ultraviolet light excitation phosphor (trade name: QKL65E / S- manufactured by U-VIX Co., Ltd.). C1) Except for this, crushed phosphor-2 (average particle diameter 10 μm) was obtained in the same manner.

Embodiment 3

[0230] Except that a natural quartz glass substrate was used instead of the synthetic quartz glass substrate-1 used in Example 1, the quartz glass member for wavelength conversion of Example 3 was produced in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com