A preparation method of hollow carbon fiber with controllable size

A carbon fiber and hollow technology, applied in hollow filament manufacturing, fiber chemical characteristics, rayon manufacturing, etc., can solve problems such as difficult mass production, poor operational stability, harsh conditions, etc., to improve operability and controllability The effects of high stability, reduced preparation cost, and mild experimental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

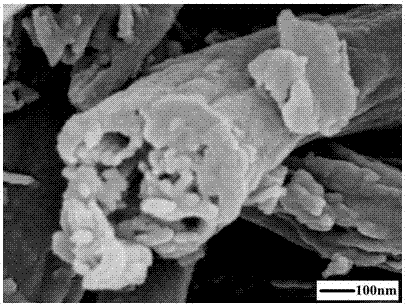

Embodiment 1

[0031] a. Weigh 0.45g MnSO 4 ·H 2 O and 1g KMnO 4 Dissolve them in 30mL deionized water and stir magnetically until the solid is completely dissolved. MnSO4·H 2 Pour O solution into KMnO 4 In the solution, continue to stir until the mixture gradually becomes a brownish yellow suspension. Subsequently, the brown-yellow suspension was transferred to a 100 mL stainless steel hydrothermal reactor and reacted at a constant temperature of 160° C. for 12 h. After the reaction, the precipitate in the kettle was filtered under reduced pressure, washed with distilled water and absolute ethanol 3 times, and dried to obtain MnO 2 Metal oxide nanorods.

[0032] b. Weigh 1.5g of PAN, dissolve it in 15g of DMF, and stir magnetically until it is completely dissolved. Then put 0.5g MnO 2 The metal oxide nanorods are continuously stirred and mixed evenly to obtain a spinning solution.

[0033] c. The environmental temperature of electrospinning is ≤40℃, and the environmental humidity is ≤30%. The...

Embodiment 2

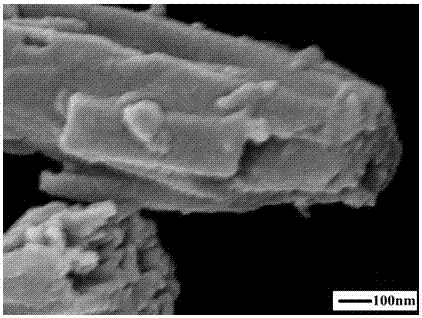

[0037] a. Weigh 0.45g MnSO 4 ·H 2 O and 1g KMnO 4 Dissolve them in 30mL deionized water and stir magnetically until the solid is completely dissolved. MnSO4·H 2 Pour O solution into KMnO 4 In the solution, continue to stir until the mixture gradually turns into a brownish yellow suspension. Subsequently, the brown-yellow suspension was transferred to a 100 mL stainless steel hydrothermal reactor, and reacted at 160° C. for 18 hours at a constant temperature. After the reaction, the precipitate in the kettle was filtered under reduced pressure, washed with distilled water and absolute ethanol 3 times, and dried to obtain MnO 2 Metal oxide nanorods.

[0038] b. Weigh 1.5g of PAN, dissolve it in 15g of DMF, and stir magnetically until it is completely dissolved. Then put 0.5g MnO 2 The metal oxide nanorods are continuously stirred and mixed evenly to obtain a spinning solution.

[0039] c. The environmental temperature of electrospinning is ≤40℃, and the environmental humidity is ≤3...

Embodiment 3

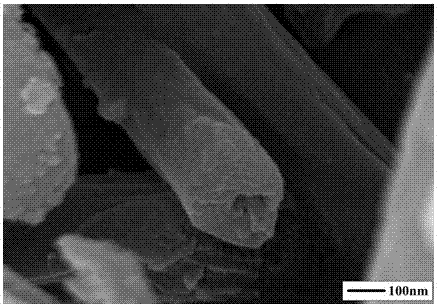

[0043] a. Weigh 0.45g MnSO 4 ·H 2 O and 1g KMnO 4 Dissolve them in 30mL deionized water and stir magnetically until the solid is completely dissolved. MnSO4·H 2 Pour O solution into KMnO 4 In the solution, continue to stir until the mixture gradually turns into a brownish yellow suspension. Subsequently, the brown-yellow suspension was transferred to a 100 mL stainless steel hydrothermal reactor, and reacted at a constant temperature at 160° C. for 24 h. After the reaction, the precipitate in the kettle was filtered under reduced pressure, washed with distilled water and absolute ethanol 3 times, and dried to obtain MnO 2 Metal oxide nanorods.

[0044] b. Weigh 1.5 g of PAN, dissolve it in 15 g of DMF, and stir magnetically until it is completely dissolved. Then put 0.5g MnO 2 The metal oxide nanorods are continuously stirred and mixed uniformly to obtain a spinning solution.

[0045] c. The environmental temperature of electrospinning is ≤40℃, and the environmental humidity is ≤...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com