A method for solving the transportation difficulty of a super large support arm base and a detachable support arm base

A dismantling, base technology, applied in marine engineering, construction, barrage/weir, etc., can solve the problems of overweight and oversized arm bases, which are difficult to transport arm bases, etc., to reduce transportation weight and facilitate uniformity. The effect of transferring force and reducing the size of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

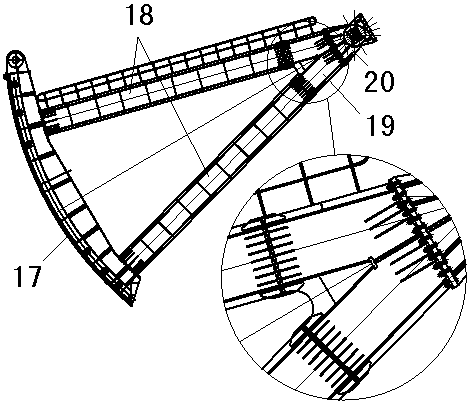

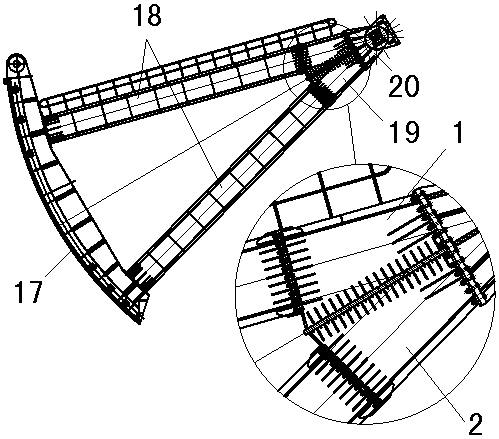

[0028] In order to solve the technical problem of the above-mentioned transportation difficulties, the present invention figure 2 As shown, the traditional integral support arm base is cut into two sections up and down along the ray direction of the fulcrum of rotation; or cut into more than three sections along the ray direction of the fulcrum of rotation to form multiple smaller parts, each smaller part It is transported by one vehicle to solve the problems of overweight, overwidth and overheight during transportation. In order to facilitate on-site assembly, the cut surface of each component is equipped with a connecting plate, and the connecting plate is provided with a number of connecting holes for connection. When the components arrive at the construction site, bolts pass through the connecting holes to connect each component. Assembles into an arm base.

[0029] figure 2 It is a schematic diagram of a double-arm arc gate formed by the technical solution of the pres...

Embodiment 2

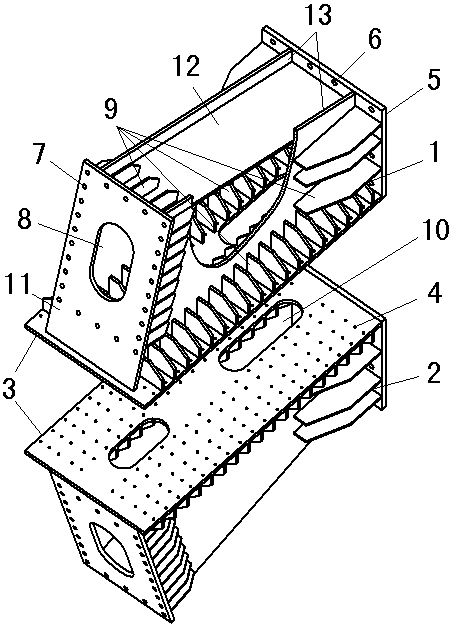

[0034] When the arc gate is particularly large, multiple sets of arms are required to support the door leaf, and the corresponding arm bases are also particularly large. Figure 4 Shown is a schematic diagram of a three-arm arc gate formed by adopting the technical solution of the present invention. Figure 4 The partially enlarged part in is a schematic diagram of the three-arm detachable arm base of the present invention. Figure 5 yes Figure 4 Schematic breakdown of the structure.

[0035] Depend on Figure 4 and Figure 5 It can be seen that the three-arm detachable arm base is composed of an upper section 1 of the arm base and a lower section 2 of the arm base, and is located between the upper section 1 of the arm base and the lower section 2 of the arm base. The middle section 14 of the support arm base is assembled, and the upper section, the middle section and the lower section of the support arm base are all box-shaped structures, and the two box-shaped structure...

Embodiment 3

[0039] When cutting the base of the arm, it is not necessary to take the form of equal division. It is also possible to cut the support arm base into sections of different sizes according to the specific conditions of the project. Such as Figure 6 as shown, Figure 6 is a three-arm detachable arm base, Figure 6 Cutting line 16 in will cut the base of the arm into two parts of unequal size. The upper section 1 of the support arm base is smaller than the lower section 2 of the support arm base, and the upper section 1 of the support arm base is only connected with one group of support arms; while the lower section 2 of the support arm base is connected with two groups of support arms. In order to improve the strength of the lower section 2 of the support arm base, a Y-shaped middle web 15 can be added in the lower section 2 of the support arm base, and two front end plates 11 are welded at different angles to cooperate with the door leaves of the arc gate.

[0040] Detaile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com