Three-core power cable phase current detection method based on magnetic sensors

A power cable and magnetic sensor technology, applied in the direction of only measuring current, measuring current/voltage, instruments, etc., can solve problems such as measurement delay, inability to clearly diagnose defects or fault location and type, and achieve effective detection and real-time online detection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

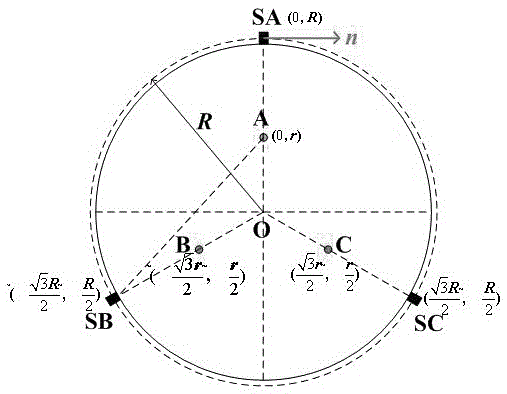

[0021] The structure of the three-core power cable used in the simulation modeling of the present invention is as follows: figure 1 As shown, the center of the cable is O, A, B, and C are the positions of the three-phase core wires, and the distance from the cable center to the three-phase core wires of A, B, and C is r. Without loss of generality, the y-axis can coincide with OA, then the coordinates of point A are (0, r). The vectors from the center of the cable to the two-phase core wires of B and C, namely OB and OC, and the included angles with the x-axis are 210 degrees and 330 degrees respectively, so the coordinates of point B are (- r / 2,-r / 2), the coordinates of point C are ( r / 2, -r / 2). The currents of the three-phase core wires of A, B, and C are respectively I A , I B and I C .

[0022] The magnetic sensor installation positions SA, SB, and SC are respectively the intersection points of the extension lines of OA, OB, and OC and the surface of the cable. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com