Intelligent sorting machine with annular crossed belt

A cross-belt sorting and ring-shaped technology, applied in sorting and other directions, can solve the problems of low efficiency of batch sorting and inability to intelligently sort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

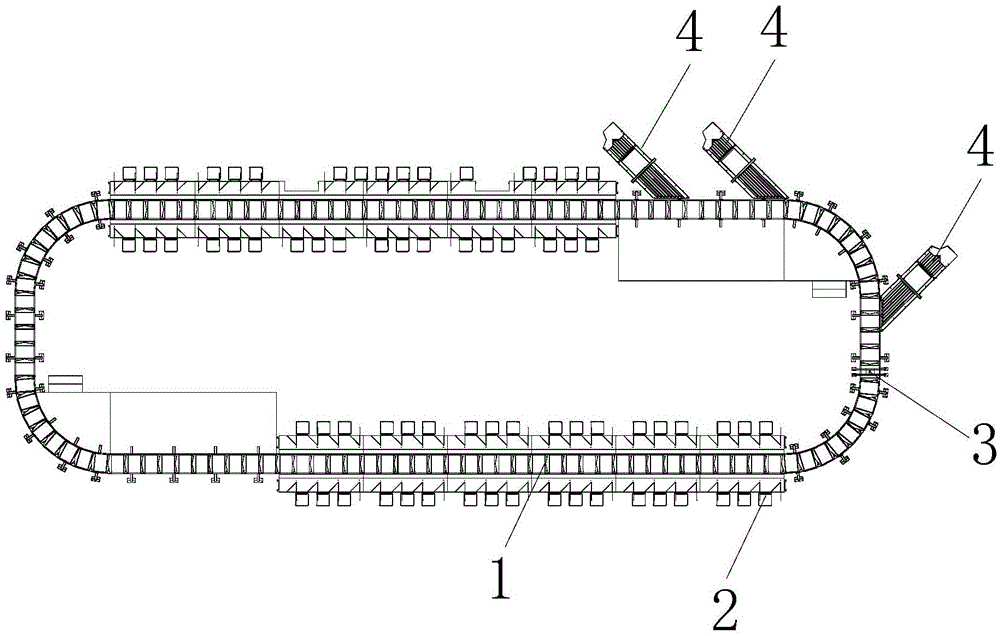

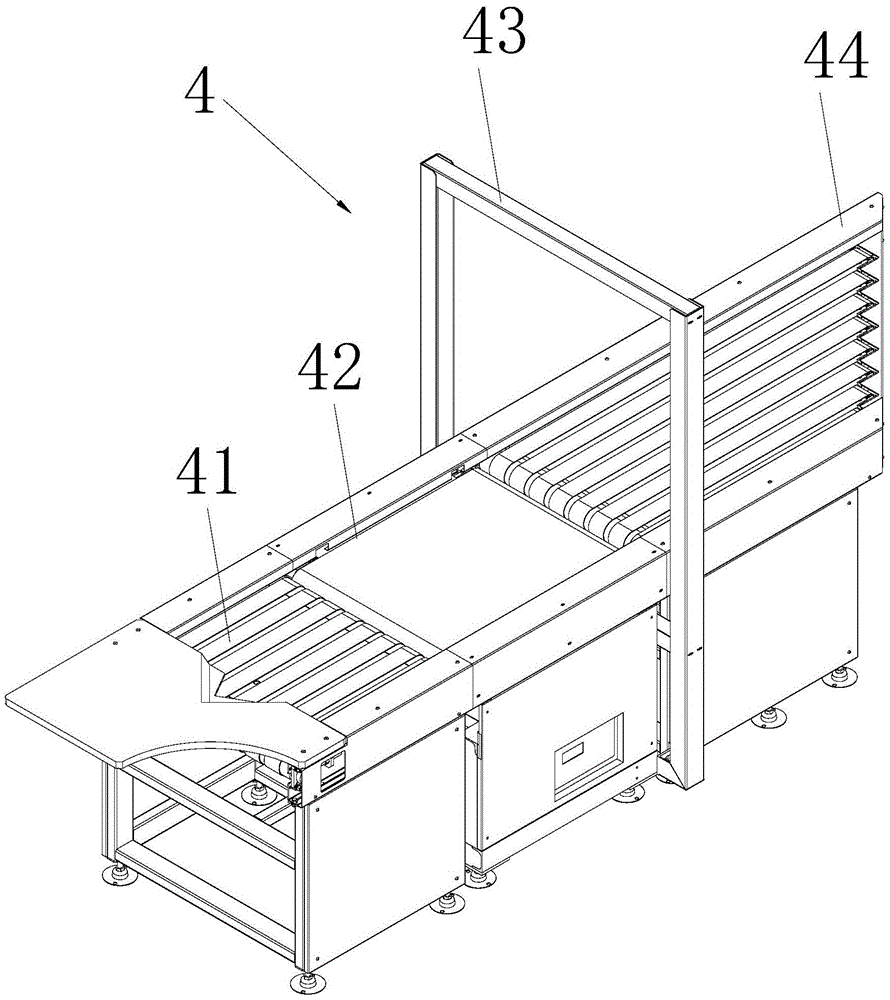

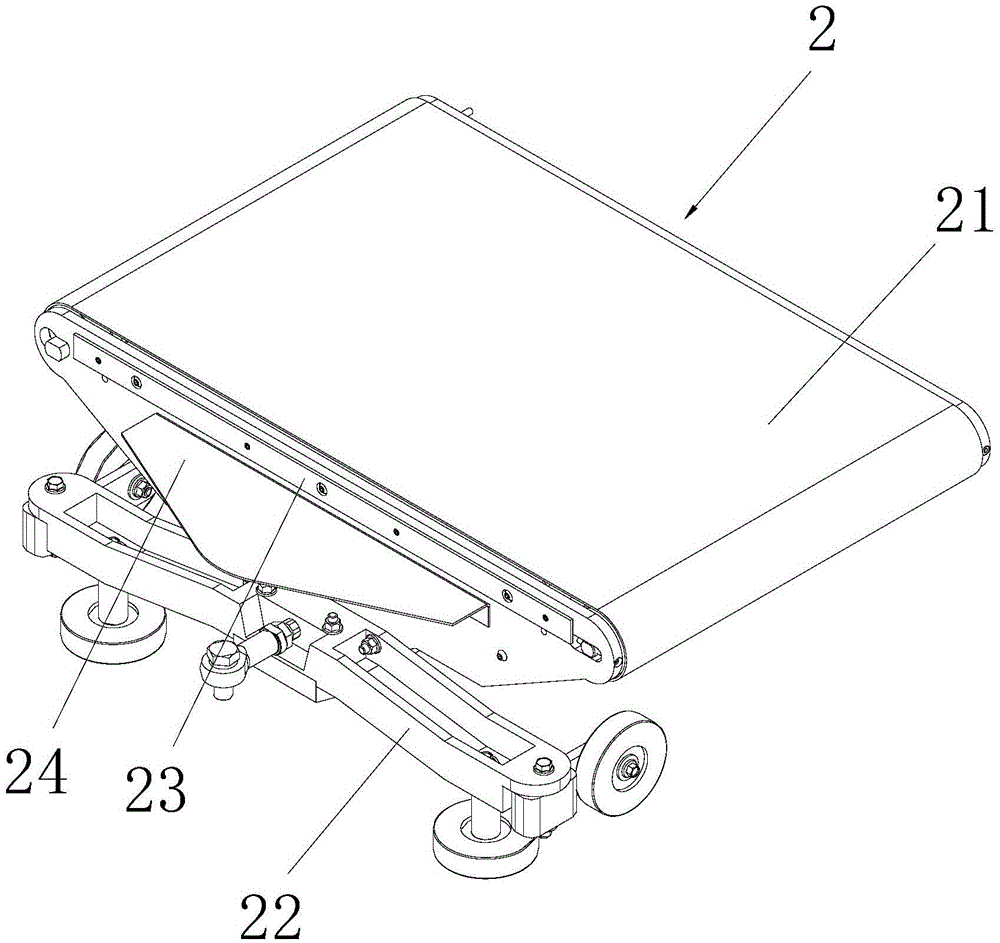

[0015] The present invention will be further described below in conjunction with accompanying drawing and preferred embodiment, see Figure 1~4 As shown, the present invention includes: a conveyor belt 1, a sorting gap unit 2, a barcode scanner 3, and a bag-up platform 4. The conveyor belt 1 is an annular structure, and several sorting gap units 2 are provided on both sides of the conveyor belt 1. , the outside of the conveyor belt 1 is provided with a bag-up platform 4, and the conveyor belt 1 is also provided with a barcode scanner 3, and the bag-up platform 4 is composed of a feeding conveying device 41, an automatic weighing device 42, and a measuring light curtain frame 43, 45 degrees The feeding conveying device 44 is formed, and the sorting gap unit 2 includes a belt 21, a support 22, a rolling roller 25, and a rolling platform 26. The support 22 is provided with a rolling roller 25 and a rolling platform 26, and the rolling platform 26 is provided with several concave h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com