An electric pole mould repairing lathe

A mold and lathe technology, which is applied in the field of pole mold maintenance devices, can solve problems affecting the stability of steel molds, affecting the quality of concrete pole molding, and affecting the effect of concrete rotation and centrifugation, achieving excellent molding quality, good economic value and The effect of social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The implementation of the present invention is illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

[0019] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

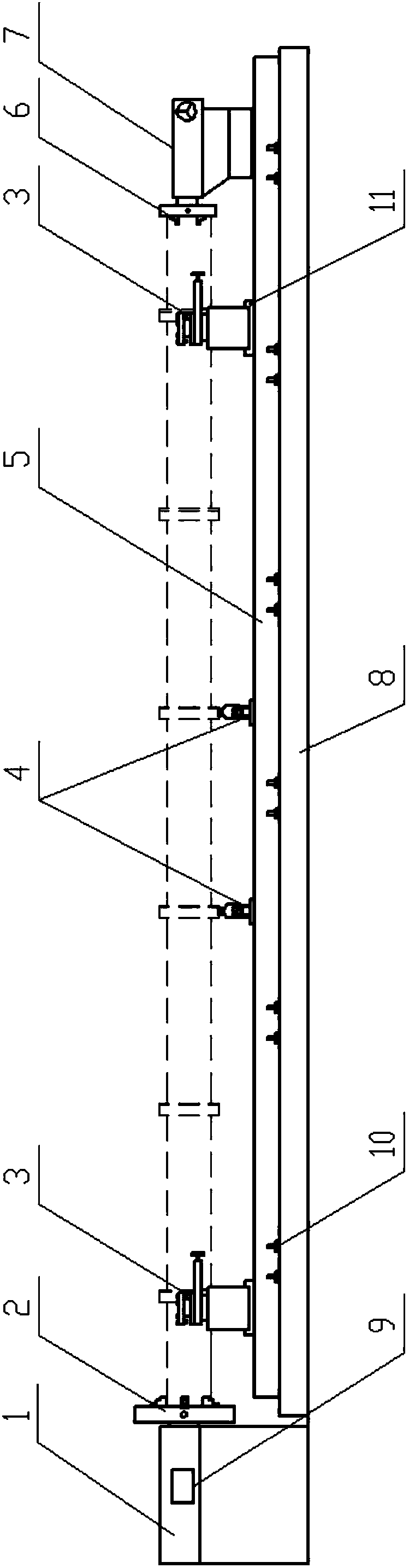

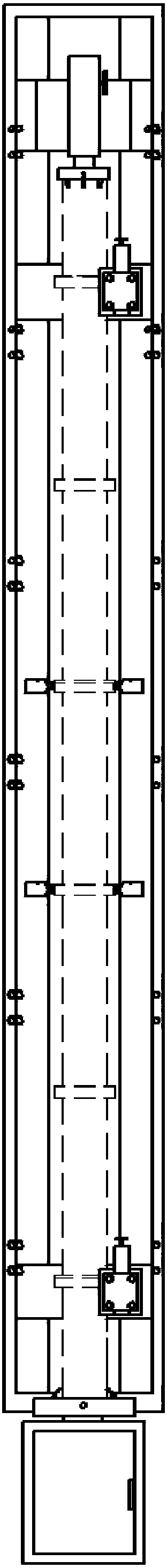

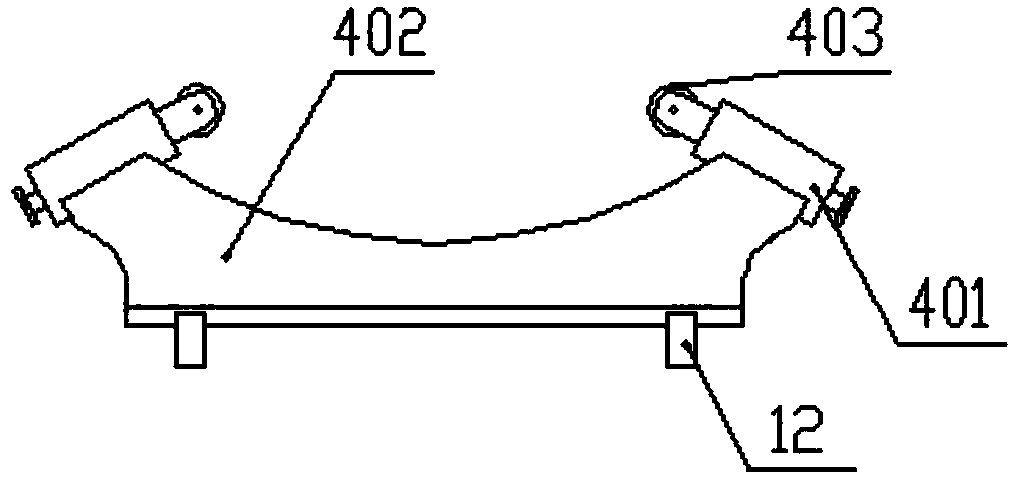

[0020] Such as figure 1 Shown in -2, a kind of pole mold maintenance lathe comprises the concrete base 8 that comprises bedside box 1 and cuboid structure; Described bedside box 1 is provided with motor, and described motor links to each other with transmission mechanism, and described transmission mechanism It is mainly composed of a belt and a pulley. The output shaft of the motor is provided with a pulley. The pulley transmits the torque to the output pulley after several stages of pulley speed change. The output shaft connected to the output pulley is provided with a transition plate. , the transiti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com