Material supply automatic switching system used for pre-mixed grinding material water jet equipment

An abrasive water jet, automatic switching technology, applied in the abrasive feeding device, the used abrasive processing device, abrasive and other directions, can solve the problem that the abrasive in the tank cannot be fully utilized, and it is impossible to accurately determine the switching timing and cutting efficiency of the two tanks. drop and other problems to achieve the effect of improving cutting efficiency, responding in time, and avoiding cutting stagnation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

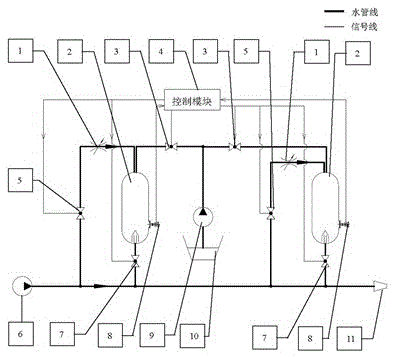

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0021] An automatic material supply switching system for pre-mixing abrasive water jet equipment, including: throttle valve 1, high-pressure tank 2, feed ball valve 3, control module 4, bypass ball valve 5, high-pressure water pump 6, main road ball valve 7. Tuning fork density meter 8, diaphragm pump 9, hopper 10, nozzle 11.

[0022] The water supply of the two high-pressure tanks is controlled by the bypass ball valve 5, the water supply of the nozzle is controlled by the main road ball valve 7, and the feed material of the two high-pressure tanks is controlled by the feed ball valve 3. The abrasive concentration in the high-pressure tank is monitored in real time by the tuning fork density meter 8, and then the obtained abrasive con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com