Device for maintaining adhesion coefficient of wheel rail

An adhesion coefficient, wheel-rail technology, used in transportation and packaging, railway vehicle wheel guards/buffers, railway car body parts, etc., can solve problems such as limited effect, reduced adhesion coefficient, wheelset and rail surface damage, etc. To achieve the effect of reducing the frequency of sanding, stabilizing the adhesion coefficient, and improving operational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

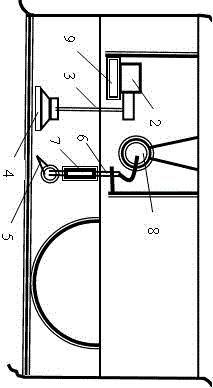

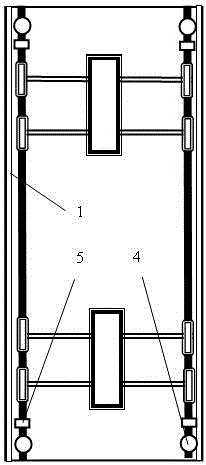

Embodiment 1

[0025] Embodiment 1: Driving when there is obvious oil stain on the rail surface or there are attachments such as leaves; the train operator automatically opens the cabin door of the train equipment through the control system, and then brushes the disc 4 successively through the lifting platform 9 and the transmission device 10. and the air knife 5 is lowered to the rail surface, start the motor 2 and the fan 8 respectively, so that the disc brush 4 starts to clean the rail surface and dry the rail surface with the strong wind of the air knife 5. When it is necessary to end the rail surface cleaning work, first cut off the motor 2 and the The power supply of the blower fan 8, then the disc brush 4 and the air knife 5 are retracted into the equipment compartment through the control system to manipulate the lifting platform 9 and the transmission device 10.

Embodiment 2

[0026] Embodiment 2: Driving in wet weather or foggy weather; the train operator automatically opens the cabin door of the train equipment cabin through the control system, then manipulates the transmission device 10 to lower the air knife 5 to the rail surface, starts the fan 8, and turns on the electric heating device 7 , use the strong hot air of the air knife 5 to dry the rail surface. When it is necessary to end the rail surface drying operation, first cut off the power supply of the electric heating device 7, and then cut off the power supply of the fan 8 after a few minutes, and then manipulate the transmission device 10 to retract the air knife 5 equipment compartment.

Embodiment 3

[0027] Embodiment 3: Driving in rainy, snowy or frosty weather; the train operator automatically opens the cabin door of the train equipment cabin through the control system, and then successively lowers the disc brush 4 and the air knife 5 to the rail surface through the lifting platform 9 and the transmission device 10 , start the motor 2 and fan 8 respectively, and then start the electric heating device 7 to make the disc brush 4 start to clean the rail surface and dry the rail surface with the strong hot air of the air knife 5. When it is necessary to end the rail surface cleaning and drying operation, first cut off The power supply of the electric heating device 7 cuts off the power supply of the motor 2 and the fan 8 after a few minutes, and then the disc brush 4 and the air knife 5 are retracted into the equipment compartment by the control system manipulation of the lifting platform 9 and the transmission device 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com