Preparation method of ferric salt solution

A solution and iron salt technology, applied in chemical instruments and methods, water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of poor pollution removal ability and high price of divalent iron salt coagulant, Achieve good decontamination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0013] Specific embodiment one: the preparation method of iron salt solution of this embodiment is realized according to the following steps:

[0014] 1. Weigh the ferrous salt solid and place it in the reaction vessel;

[0015] 2. Add concentrated acid dropwise to the surface of the ferrous salt solid in the reaction vessel to obtain acid-treated ferrous salt;

[0016] 3. Add distilled water to the reaction vessel to dissolve the acid-treated ferrous salt to obtain an iron salt solution with a pH of 2 to 7;

[0017] Wherein the ferrous salt described in step 1 is a mixture of one or more of ferrous chloride, ferrous sulfate, ferrous nitrate and ferrous perchlorate in any ratio.

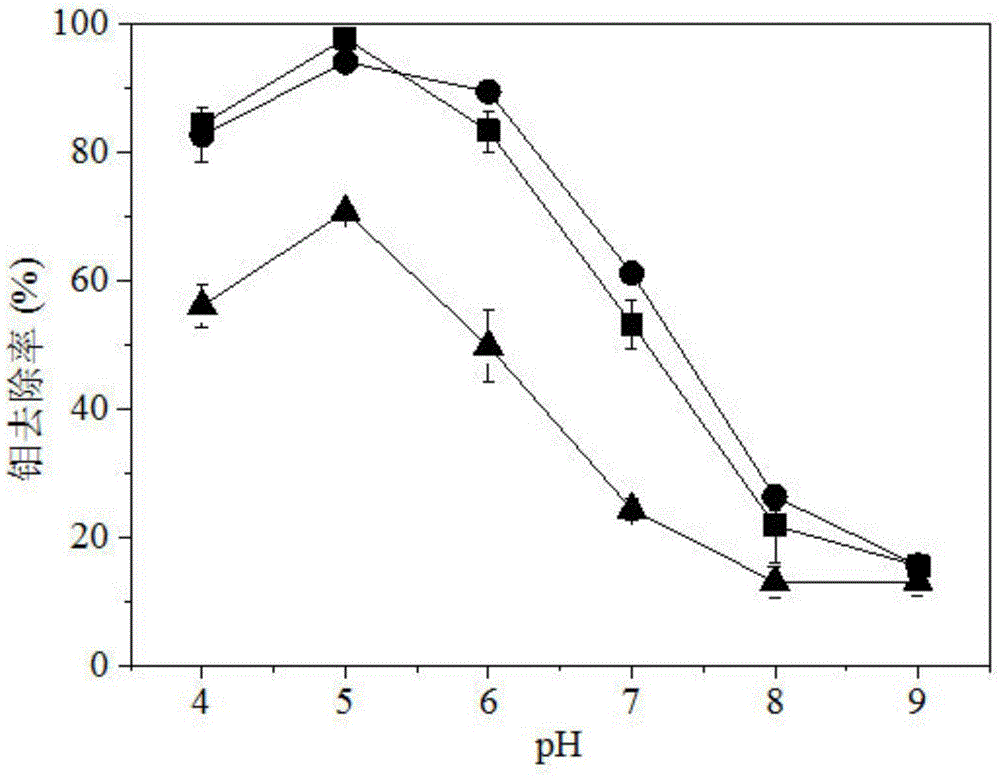

[0018] In this embodiment, concentrated acid is used to oxidize ferrous iron into ferric iron, and the obtained iron salt solution has a decontamination effect equivalent to that of ordinary ferric salt. The reaction between concentrated acid and ferrous salt can convert solid ferric The valent iro...

specific Embodiment approach 2

[0019] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the form of the solid ferrous salt described in step 1 is granular or powder. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0020] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the concentrated acid described in step 2 is one or more mixed acids of concentrated sulfuric acid, concentrated hydrochloric acid, and concentrated nitric acid. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

[0021] When this embodiment is mixed acids, they can be mixed in any ratio.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com