Waterproof thermal-insulation paint

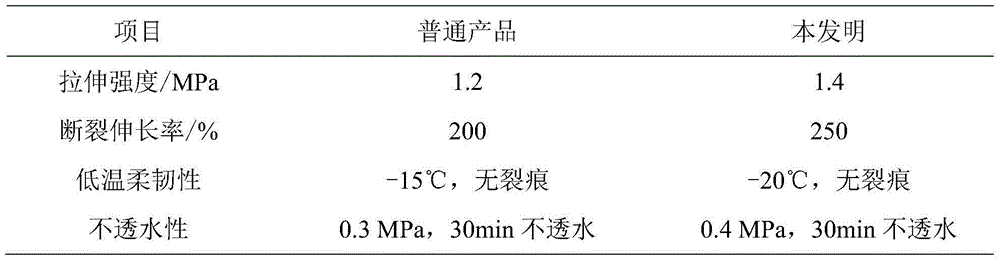

A technology for thermal insulation coatings and raw materials, applied in the direction of reflective/signal coatings, coatings, etc., can solve the problems of low elongation at break, poor waterproof and wear resistance of coatings, and achieve the effect of reducing the amount of coatings and reducing engineering costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A waterproof and heat-retaining coating is composed of the following raw materials according to mass percentage: 10% of hollow glass microspheres, 45% of elastic acrylic emulsion, 5% of infrared reflector, 5% of diatomite, 5% of additives and 30% of water. 40% of triethanolamine and 60% of tributyl phosphate in the auxiliary agent.

Embodiment 2

[0025] A waterproof and heat-retaining coating is composed of the following raw materials in mass percentage: 20% of hollow glass microspheres, 30% of elastic acrylic emulsion, 10% of infrared reflector, 10% of diatomite, 1% of auxiliary agent and 29% of water. Additives include 50% sodium hexametaphosphate and 50% tributyl phosphate.

Embodiment 3

[0027] A waterproof and heat-retaining coating is composed of the following raw materials according to mass percentage: 18% of hollow glass microspheres, 42% of elastic acrylic emulsion, 8% of infrared reflector, 9% of diatomite, 3% of auxiliary agent and 20% of water. 45% lithium magnesium silicate and 55% tributyl phosphate are included in the additives.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com