Special vertical lower cantilever hollow screw rod vacuum pump for pharmaceutical chemical engineering

A technology of hollow screw and vacuum pump, applied in the direction of rotary piston pump, rotary piston type/swing piston type pump combination for elastic fluid, components of pumping device for elastic fluid, etc., to eliminate screw clogging, solve Effects of Thermal Expansion Problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

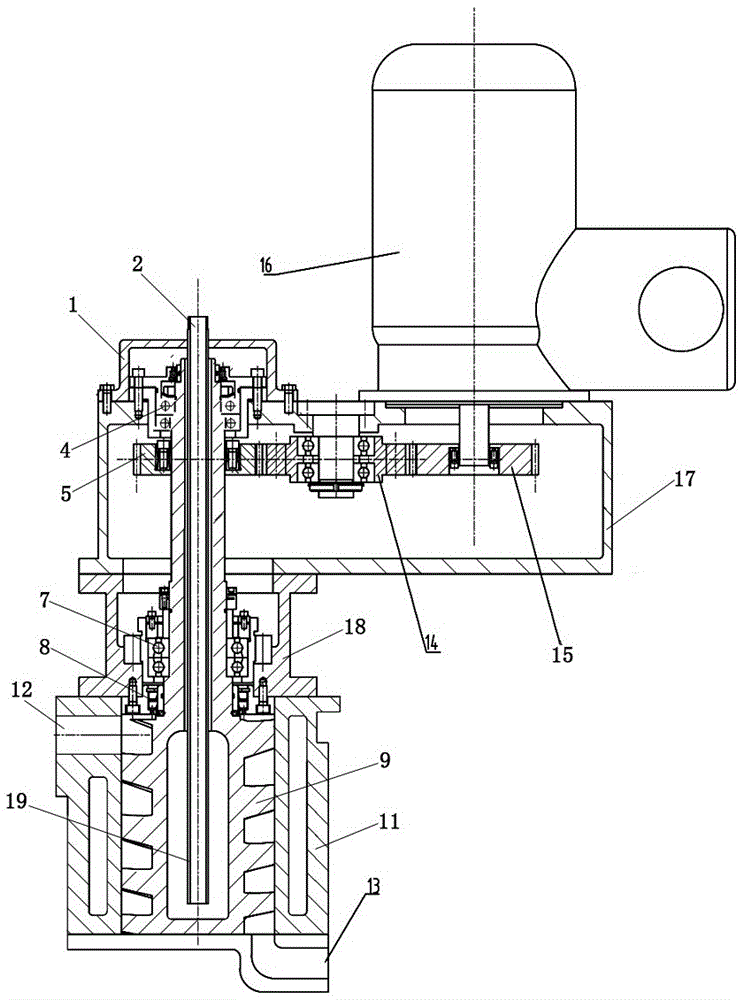

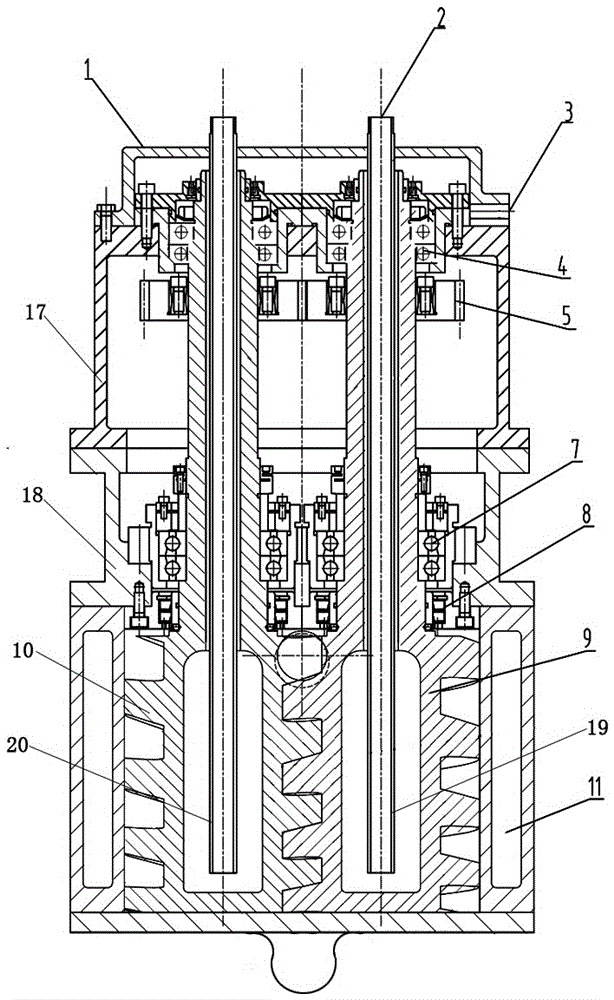

[0035] like figure 1 , figure 2 As shown, the screw vacuum pump of the present invention includes a pump casing 11, an upper bearing housing 17, a lower bearing housing 18, a driving screw 9, a driven screw 10, a motor 16 and the like. The pump casing 11 is a box-shaped casing with an elliptical cross section, and the upper end of the side wall of the pump casing 11 is provided with an air inlet 12 communicating with the side wall of the pump chamber ( figure 2 ), at the bottom of the pump casing 11, there is an air outlet 13 communicating with the bottom surface of the pump chamber ( figure 2 ). The lower bearing housing 18 is an elliptical box with an oval section similar to the pump housing 11, and the upper bearing box 17 is provided with an overhang ( figure 2 ), a motor 16 is connected to the top of the overhang, and a gear transmission mechanism is connected inside the overhang.

[0036] In the present invention, the lower bearing housing 18 is moved up, and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com