Refrigeration system with filling level monitoring function

A refrigeration system, refrigerant technology, applied in the field of vehicle equipment, can solve problems such as expansion parts or refrigerant circuit blockage, compressor risk, wrong refrigerant state, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

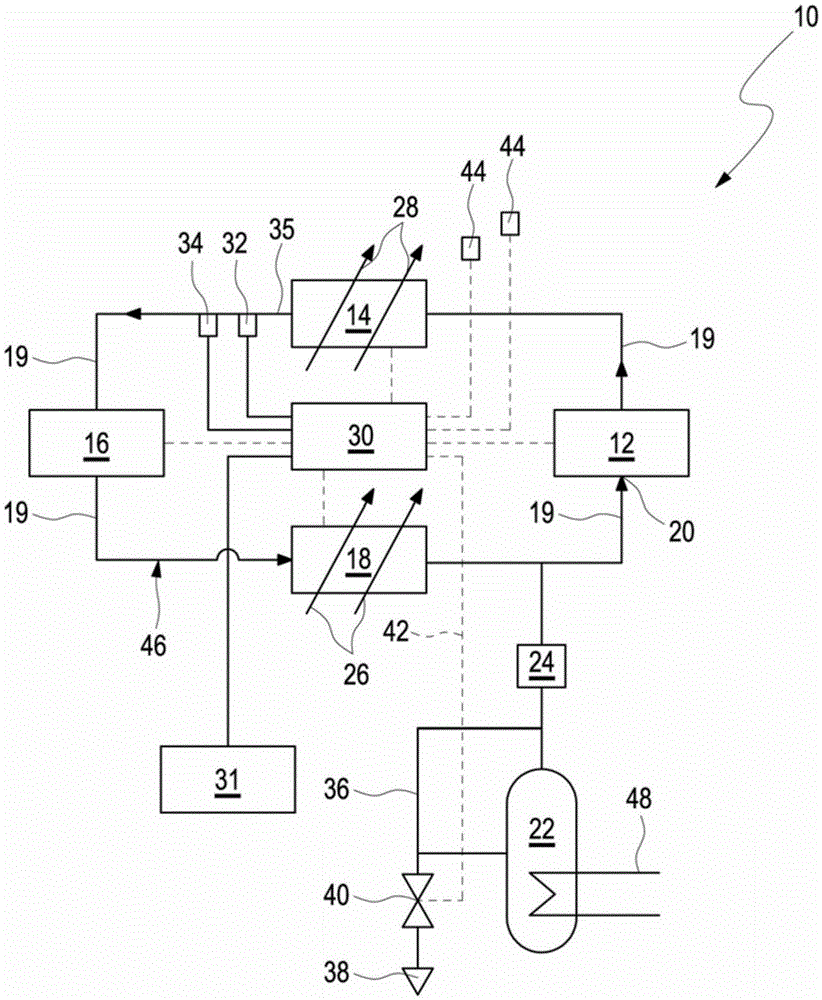

[0076] figure 1 is a schematic diagram of a refrigeration system 10 utilizing the refrigerant CO 2 run and can be used on the vehicle. CO 2 Also known as carbon dioxide and R-744. The refrigeration system 10 comprises a closed refrigerant circuit 46 with a compressor 12 , downstream of which a gas cooler 14 is arranged on the high-pressure side. The latter is followed by an expansion device 16 , through which the circulating refrigerant passing there is supplied in expanded and cooled form to an evaporator device 18 , which is connected on the suction side 20 to the compressor 12 . The various components 12 , 14 , 16 and 18 of the refrigeration system 10 are connected together by a pressure line 19 .

[0077] A storage vessel 22 , in which a certain amount of refrigerant is stored, is connected to the suction side 20 or to the corresponding pressure line 19 between the output side of the evaporator device 18 and the inlet or suction side 20 of the compressor 12 . The stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com