Optical fiber end face pumping coupler for optical fiber amplifier and fabrication method of optical fiber end face pumping coupler

A fiber amplifier and fiber end face technology, which is applied in the field of lasers, can solve the problems of special fiber bundle shape requirements, difficult bundle formation, and the inability to achieve high coupling efficiency of signal laser and pump laser at the same time, achieving high coupling efficiency, high Effect of Pump Optical Coupling Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

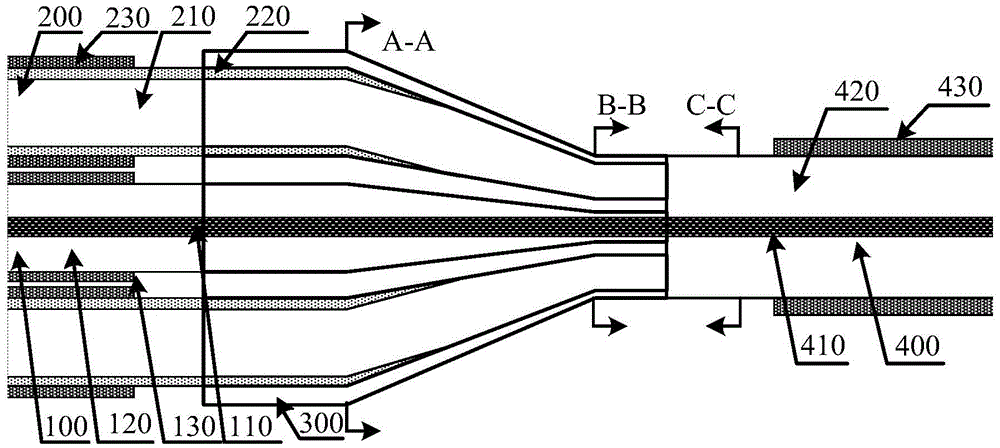

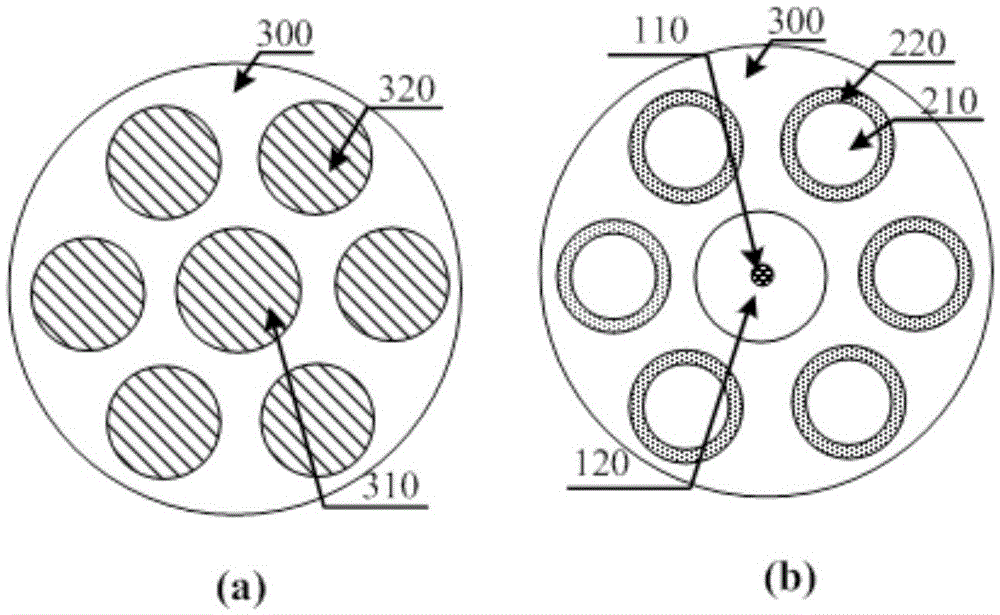

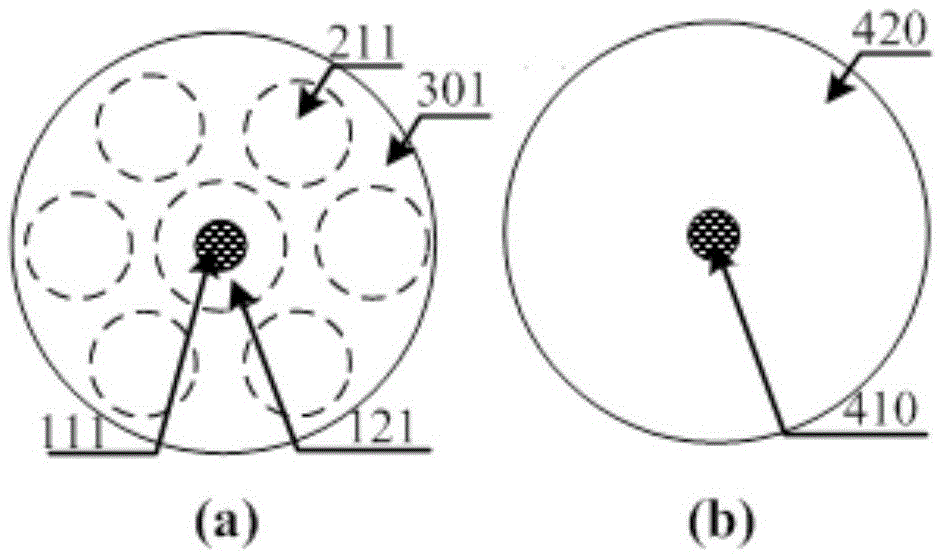

[0053] Such as Figure 1~3 As shown, this embodiment provides a fiber end-pump coupler for a fiber amplifier, and the coupler is a (6+1)×1 fiber end-pump coupler. The coupler includes a fusion cone input fiber bundle, a glass tube 300 and an output fiber 400 . The fusion cone input fiber bundle includes one input signal fiber 100 arranged on the central axis and six pumping fibers 200 uniformly distributed around the periphery of the input signal fiber 100 . Wherein the input signal fiber 100 comprises a signal fiber core 110, a signal cladding 120 wrapped on the outer wall of the signal fiber core 110 and a signal coating 130 wrapped on the outer wall of the signal cladding 120, the structures of the pump fiber and the output fiber are the same as Similar to this, the optical fiber structures used in other embodiments are also similar to this, and will not be described in detail below. Each pumping fiber 200 includes a pumping fiber core 210 , a pumping fiber cladding 220 a...

Embodiment 2

[0066] see Figure 4~6 , this embodiment is a (10+1)×1 fiber end-face coupler. The coupler includes a fused cone input fiber bundle, a glass tube 300 and an output fiber 400 . The taper input optical fiber bundle includes one input signal optical fiber 100 at the central axis and ten input pump optical fibers 200 evenly distributed around the periphery of the input signal optical fiber 100 .

[0067]The input signal fiber 100 includes a signal fiber core 110 , a signal fiber cladding 120 and a signal fiber coating 130 . Each input pump fiber 200 includes a pump fiber core 210 , a pump fiber cladding 220 and a pump fiber coating 230 . The output fiber 400 includes an output fiber core 410 , an output fiber inner cladding 420 and an output fiber coating 430 . Figure 5 (a) is a cross-sectional view of the glass tube used in this embodiment, where 310 is the signal fiber air hole, and 320 is the pump fiber air hole. Figure 5 (b) is Figure 4 The cross-sectional view of A-A ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com