Modular parallel type electromechanical actuator

An electromechanical actuator, parallel technology, applied in the direction of electromechanical devices, electric components, electrical components, etc., can solve the problems of electromechanical actuators with complex structure, cumbersome assembly process, unfavorable maintenance, etc., to shorten the design cycle and compact structure , The effect of saving installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment a kind of that the present invention provides is introduced:

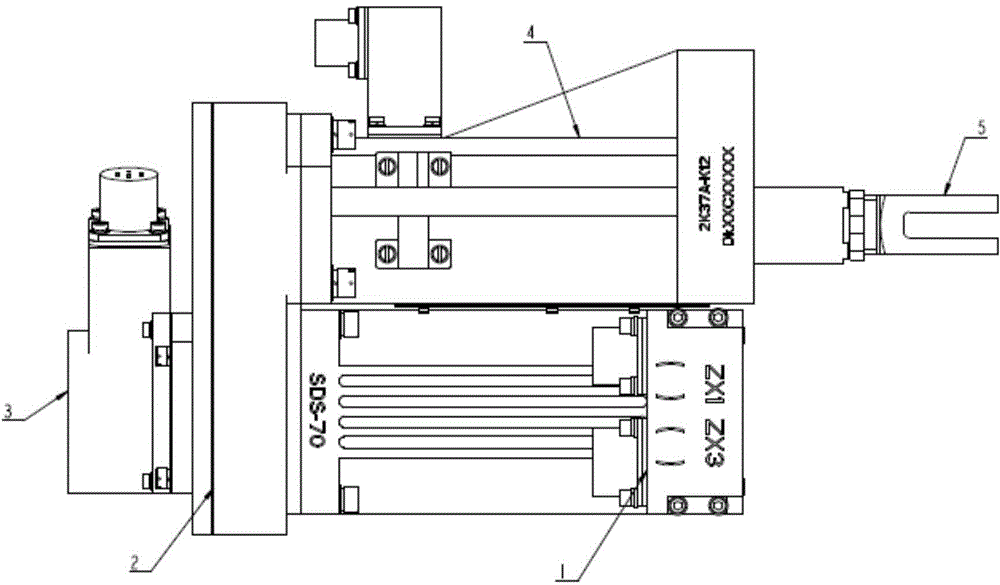

[0026] A parallel electromechanical actuator with a modular design, including a servo motor 1, a gear reducer 2, an electromagnetic lock 3, a ball screw assembly 4 and a bolt assembly 5, wherein the output shaft of the servo motor 1 and the gear reducer 2 The pinion shaft of the servo motor 1 is connected to the input shaft of the screw assembly 4, the servo motor 1 is arranged in parallel with the ball screw assembly, and the electromagnetic lock 3 is installed on the housing of the gear reducer 2.

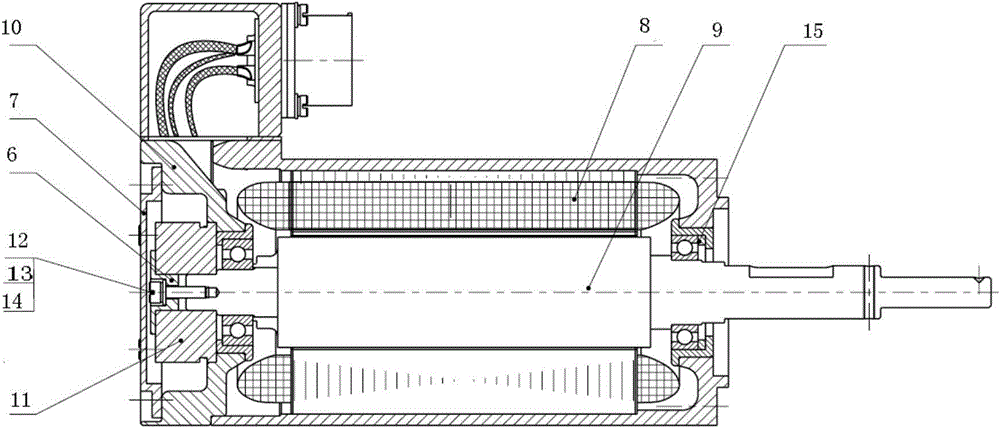

[0027] The servo motor 1 adopts a point-to-point structure of a three-phase Y winding, including a stator assembly 8, an internal rotor assembly 9, an end cover assembly 10, a rotary transformer 11, screws 12, flat elastic pads A13, flat elastic pads B14, deep grooves Ball bearings 15, wherein the stator assembly 8 is located inside the motor housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com