Bottle sterilization method and device

A sterilizing device and bottle technology, which is applied to household components, applications, household appliances, etc., can solve the problems of bottle whitening, uneven heating, uneven forming, etc., and achieve the effect of not producing whitening and preventing equipment damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

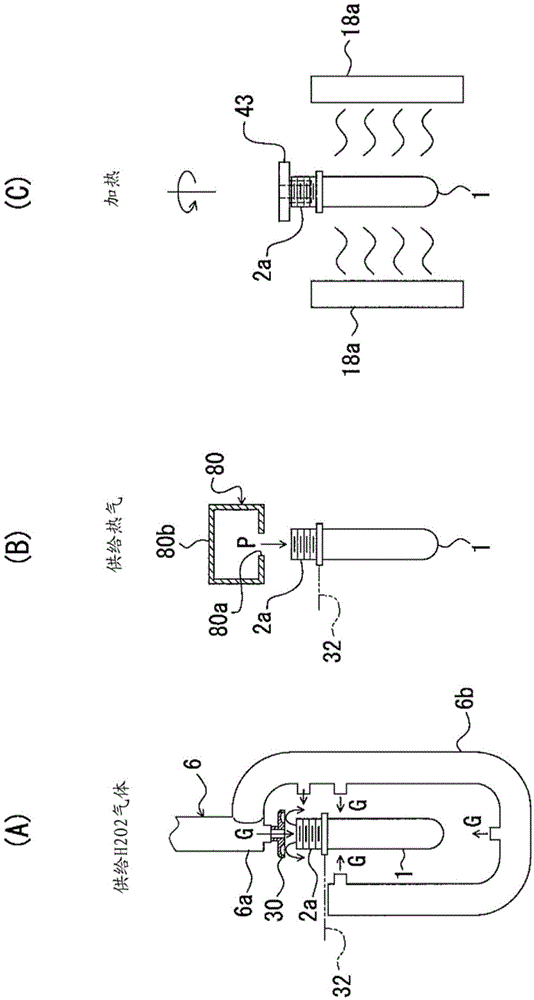

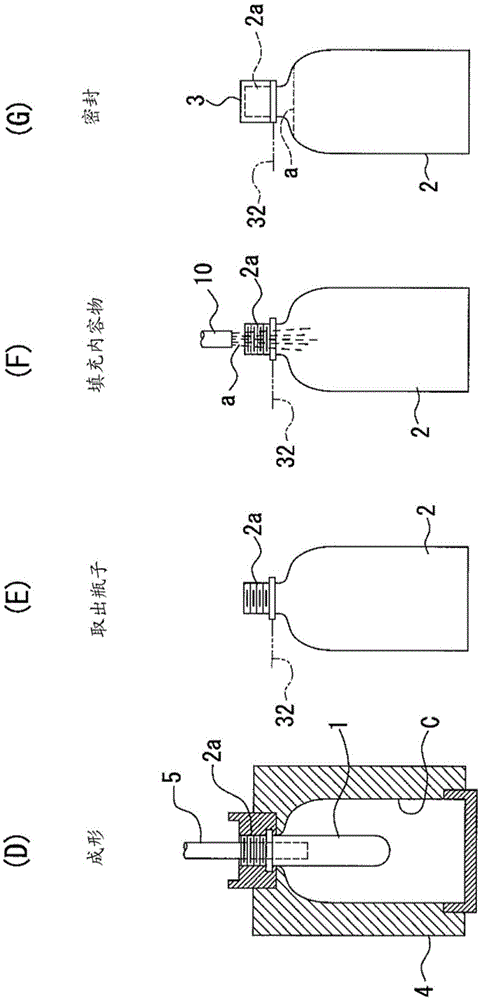

[0074] According to this Embodiment 1, by sterilizing the preform, forming the bottle into a sterile one, filling it with a sterile beverage, and sealing it with a sterile cap, as a finished product, it is possible to manufacture figure 2 Package shown in (G).

[0075] This package includes a sterile bottle 2 and a cap 3 as a cap.

[0076] In this embodiment, the bottle 2 is made of PET, but it is not limited to PET, and may be made of other resins such as polypropylene and polyethylene. Resins that dispense recycled PET can also be used. A male thread is formed on the mouth portion 2a of the bottle 2 .

[0077] The cap 3 is formed by injection molding of a resin such as polyethylene, and a female thread is formed on the inner peripheral surface of the cap 3 simultaneously with the molding.

[0078] The bottle 2 is filled with the sterilized beverage a in a state where the inside thereof has been sterilized in advance. After the beverage a is filled, the cap 3 is covered ...

Embodiment approach 2

[0175] According to this second embodiment, it is also possible to manufacture Figure 13 (K) An aseptic package including a bottle 2 and a cap 3 as shown.

[0176] The above bottle 2 as Figure 10 (A)~ Figure 13 As shown in (K), an aseptic package is formed through sterilization, molding, beverage filling, and sealing.

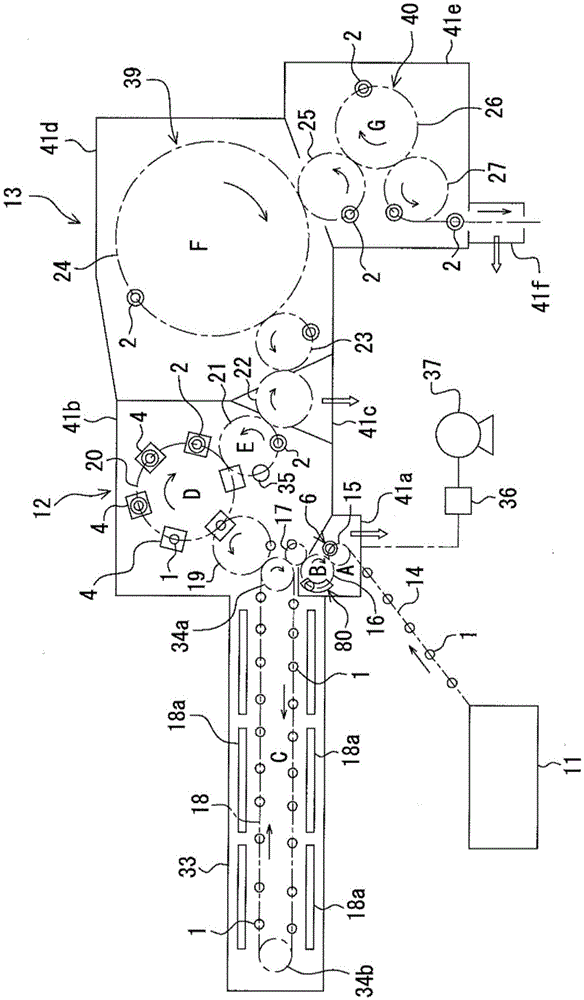

[0177] Initially, the Figure 10 The preform 1 shown in (A) is conveyed continuously at a desired speed, and the gas G or mist of the sterilizing agent or a mixture thereof is supplied to the moving preform 1 .

[0178] In addition, the sterilant is also supplied in the same manner as in Embodiment 1, and hydrogen peroxide gas G, mist, or a mixture thereof as the bactericide contacts and adheres to the inner and outer surfaces of the preform 1, whereby the adhering to the preform 1 The microorganisms on the surface of the blank 1 are sterilized or damaged.

[0179] In addition, it is also possible to Figure 10 Before blowing the gas G onto the preform...

Embodiment approach 3

[0269] In this Embodiment 3, to Embodiment 2 Figure 10 In the process of supplying the bactericide to the preform 1 shown in (A), use Figure 16 The sterilant supply nozzle 94 is shown instead of the sterilant supply nozzle 6 .

[0270] Such as Figure 16As shown, a pipe 94a extending in a substantially U-shape following the outside of the preform 1 is provided at the sterilant supply nozzle 94, and a discharge port 95 facing the outside of the preform 1 is provided on the pipe 94a. The discharge ports 95 are provided in multiple places so as to face the lower portion of the mouth portion 2 a in the preform 1 so as not to allow hydrogen peroxide as a sterilizing agent to enter the preform 1 .

[0271] Hydrogen peroxide gas G generated by the same generator as the sterilant gas generator 7 used in Embodiment 2 is blown out of the preform 1 from the discharge port 95 of the sterilant supply nozzle 94 to become gas G or mist. Or a mixture thereof is blown onto the outside of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com