Livestock and poultry meat freezing and unfreezing methods

A freezing method and technology for livestock and poultry meat, applied in the field of agricultural product processing, can solve the problems of shortening the thawing time and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

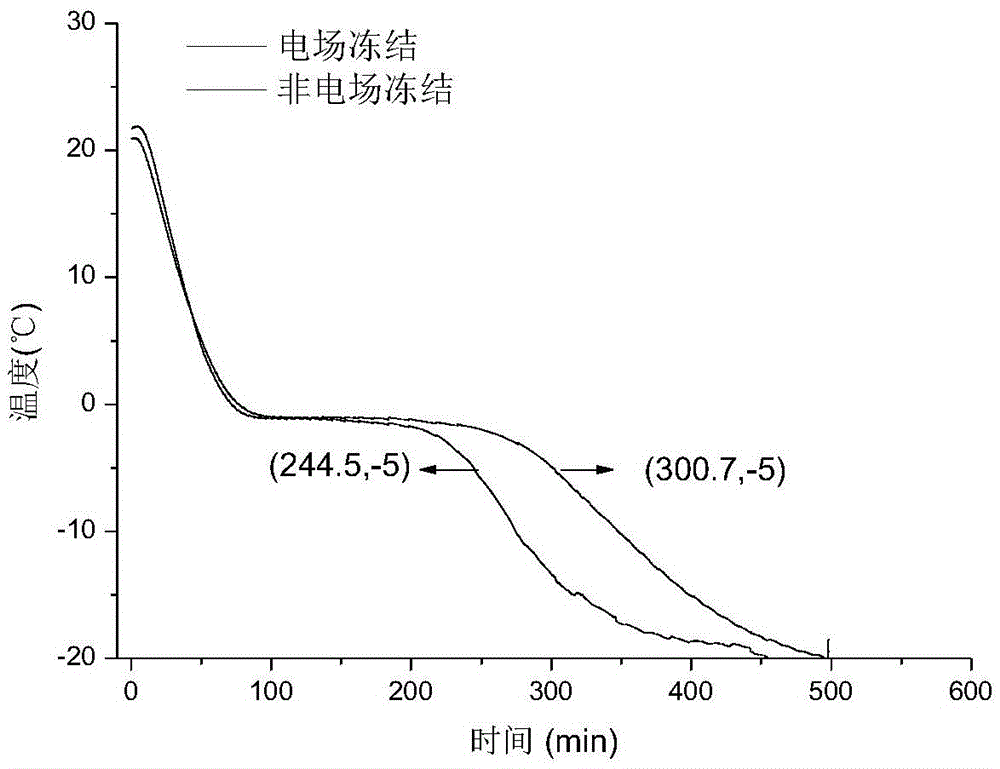

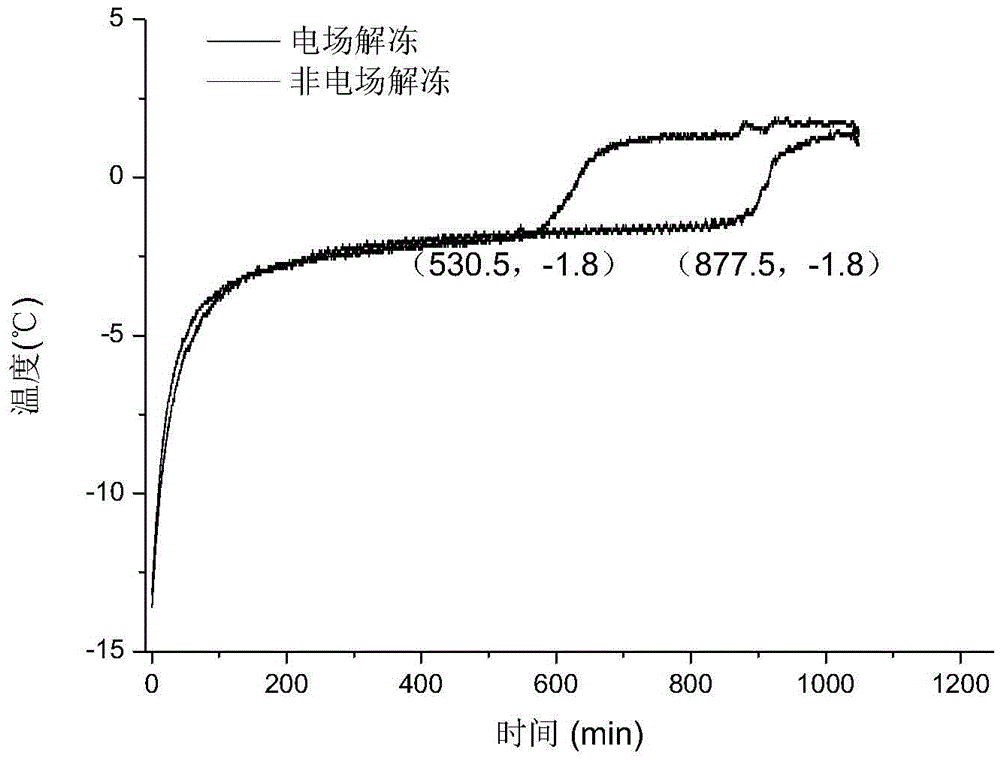

[0030] The fresh livestock and poultry meat is frozen in a freezer or freezer equipped with an electrostatic field device, the output voltage of the electrostatic field is 2400V, the current is 0.1mA, the freezing temperature is -18°C, and the freezing time is 22h.

[0031] The electrostatic field device includes an electrostatic field generating device and a discharge plate, the discharge plate is arranged in the freezer or freezer, and the discharge plate is not in contact with the livestock and poultry meat to be frozen.

Embodiment 2

[0033] Fresh poultry meat is placed in a freezer or freezer with an electrostatic field device to freeze, the output voltage of the electrostatic field is 2600V, the current is 0.3mA, the freezing temperature is -22°C, and the freezing time is 26h.

[0034] The electrostatic field device includes an electrostatic field generating device and a discharge plate, the discharge plate is arranged in the freezer or freezer, and the discharge plate is not in contact with the livestock and poultry meat to be frozen.

Embodiment 3

[0036] Place the fresh livestock and poultry meat in a freezer or freezer with an electrostatic field device to freeze. The output voltage of the electrostatic field is 2500V, the current is 0.2mA, the freezing temperature is -20°C, and the freezing time is 24h.

[0037] The electrostatic field device includes an electrostatic field generating device and a discharge plate, the discharge plate is arranged in the freezer or freezer, and the discharge plate is not in contact with the livestock and poultry meat to be frozen.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com