Precise multi-station automatic valve chamfering machine and machining method thereof

A multi-station, chamfering machine technology, applied in metal processing, metal processing equipment, machine tools suitable for grinding workpiece edges, etc., can solve the problems of low processing efficiency, reducing workpiece processing accuracy, increasing tool loss, etc. Achieve the effects of saving processing time, ensuring processing accuracy and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

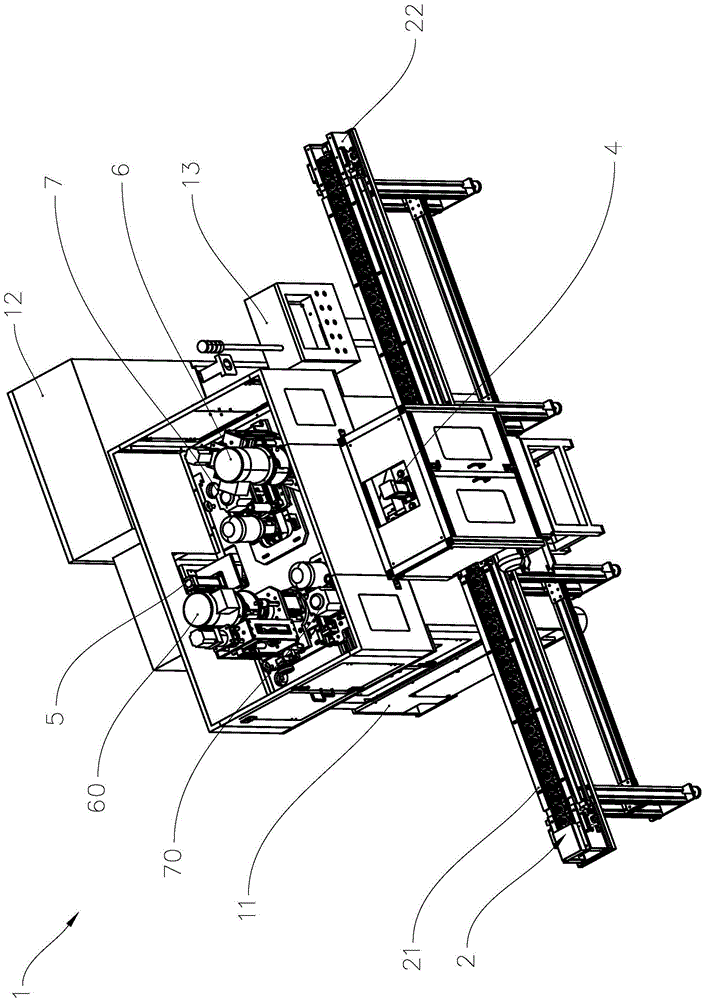

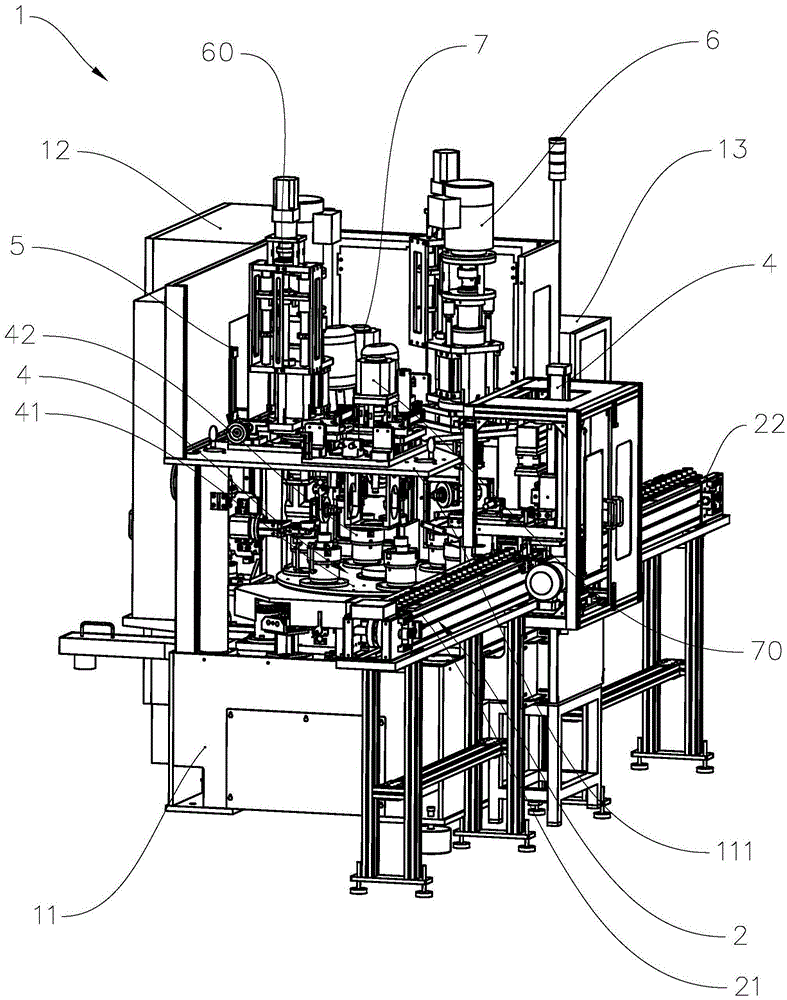

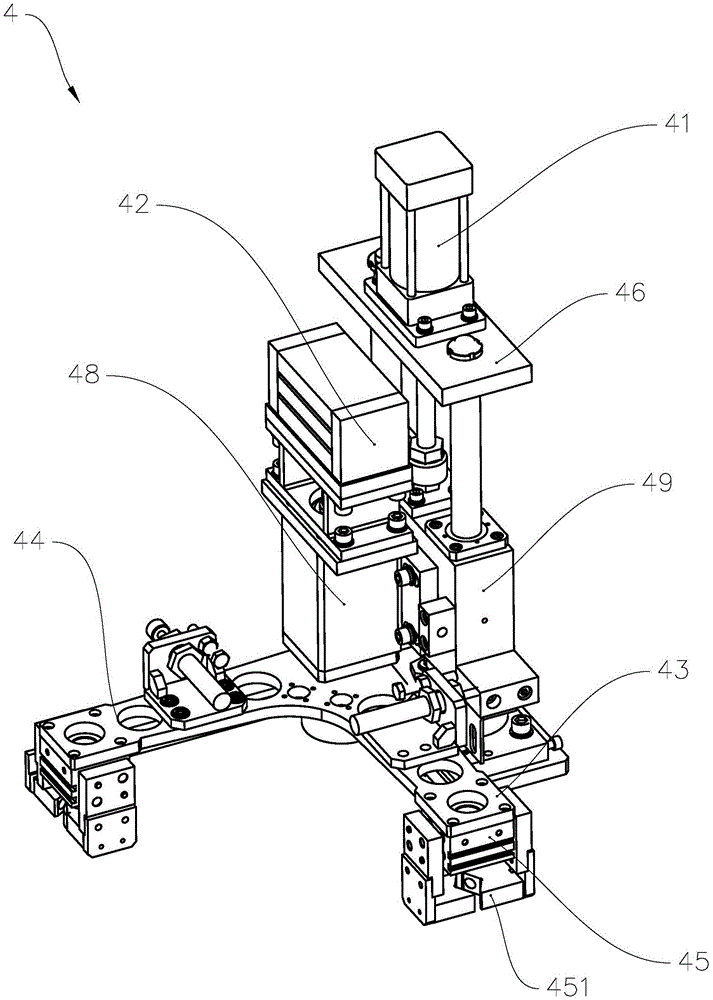

[0036] Example of piston precision multi-station automatic chamfering machine:

[0037] refer to figure 1 and figure 2 , figure 1 It is the structural diagram of the piston precision multi-station automatic chamfering machine of the present invention, figure 2 It is a structural diagram of the precision multi-station automatic chamfering machine for pistons of the present invention with some components omitted. Piston precision multi-station automatic chamfering machine 1 includes body 11, distribution box 12, console 13, belt conveyor 2, rotating device 3, loading and unloading device 4, turning device 5, first inner diameter chamfering device 6, The second inner diameter chamfering device 60 , the first outer diameter chamfering device 7 and the second outer diameter chamfering device 70 . The fuselage 11 is provided with an upper partition 111, the distribution box 12 is installed on the first side of the fuselage 11, the console 13 is installed on the second side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com