Modularized light mechanical hand

A manipulator and modular technology, applied in the field of manipulators, can solve the problems of being unable to realize industry-to-industry common use and narrow application range, and achieve the effects of light weight, easy transportation and installation, and easy installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

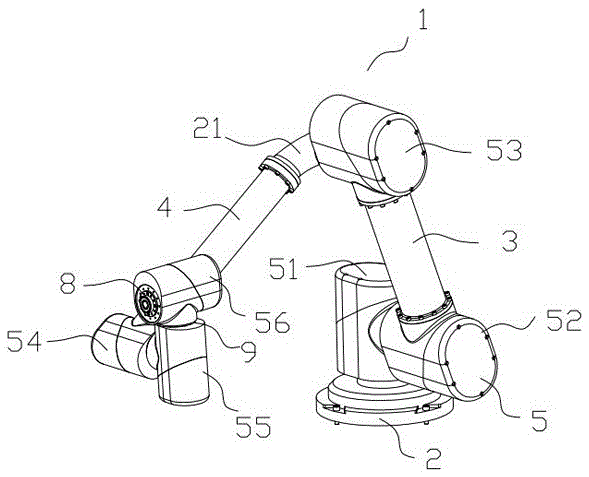

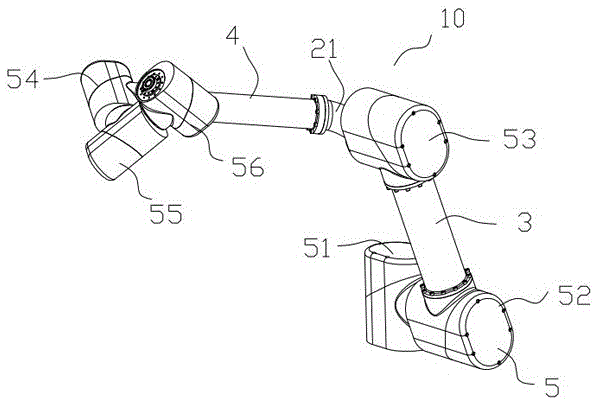

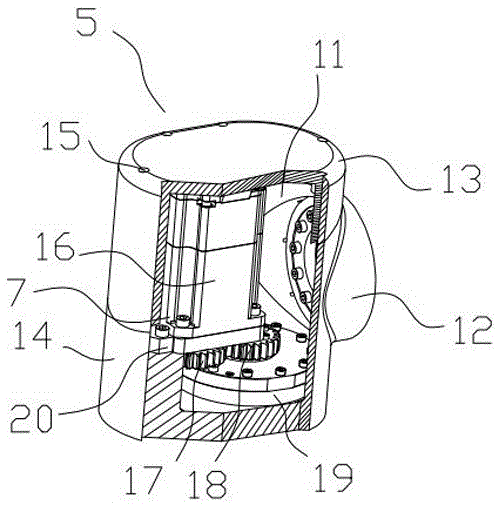

[0027] exist figure 1 , figure 2 In the shown embodiment, a modular lightweight manipulator includes a manipulator body 1. The manipulator body 1 includes a mounting base 2, a cable 6 and a rotary joint module 10. The interior of the rotary joint module 10 is a hollow structure and communicates with each other, and the cable 6 runs through Inside the hollow structure, the swivel joint module 10 includes a plurality of swivel joints 5 , the boom 3 and the small arm 4 which are combined and rotatably connected to each other. The swivel joint module 10 is fixedly connected to the mounting base 2 and can rotate in any angle in all directions. The big arm 3 , the small arm 4 and the rotary joint 5 are respectively hollow structures, and each rotary joint 5 is respectively provided with an independent power output device 7 . Revolving joints 5 are respectively provided with cavities 11 (see image 3 ), the power output device 7 is arranged inside the cavity 11 .

[0028] Each ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com