Mixing drum speed monitoring method and equipment and mixing truck

A speed monitoring and mixing drum technology, which is applied to cement mixing devices, chemical instruments and methods, control devices, etc., can solve the problems of inaccurate monitoring results of mixing drums and high monitoring costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

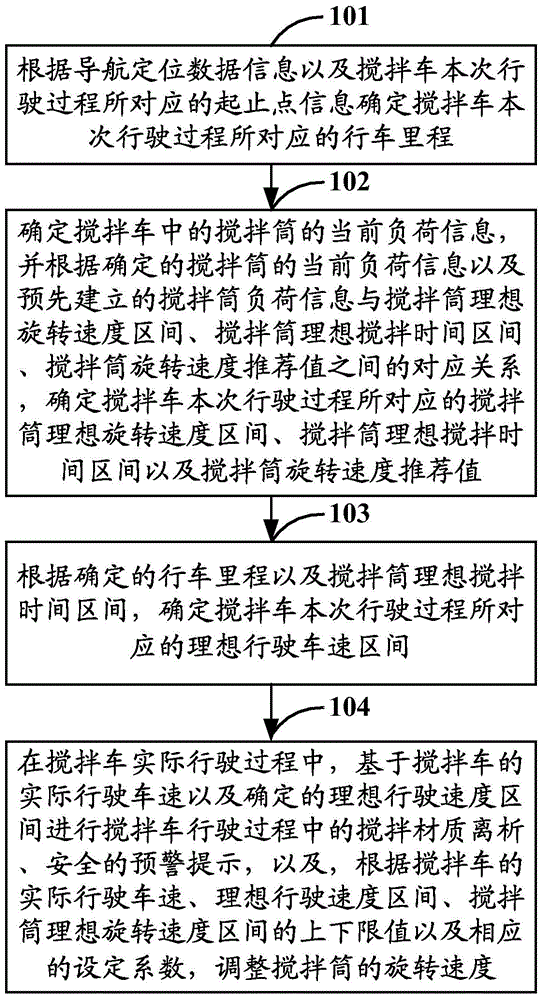

[0027] Embodiment 1 of the present invention provides a method for monitoring the speed of a mixing drum, such as figure 1 As shown, it is a schematic flow chart of the mixing drum speed monitoring method described in Embodiment 1 of the present invention, and the mixing drum speed monitoring method may specifically include the following steps:

[0028] Step 101: Determine the mileage corresponding to the current driving process of the mixer truck according to the navigation positioning data information and the corresponding start and end point information of the current driving process of the mixer truck.

[0029] Optionally, the navigation and positioning data information may be navigation and positioning data information based on GPS (Global Positioning System, Global Positioning System), or may also be navigation and positioning data information based on Beidou satellite navigation system, which is not made in the embodiment of the present invention. Any restrictions.

[...

Embodiment 2

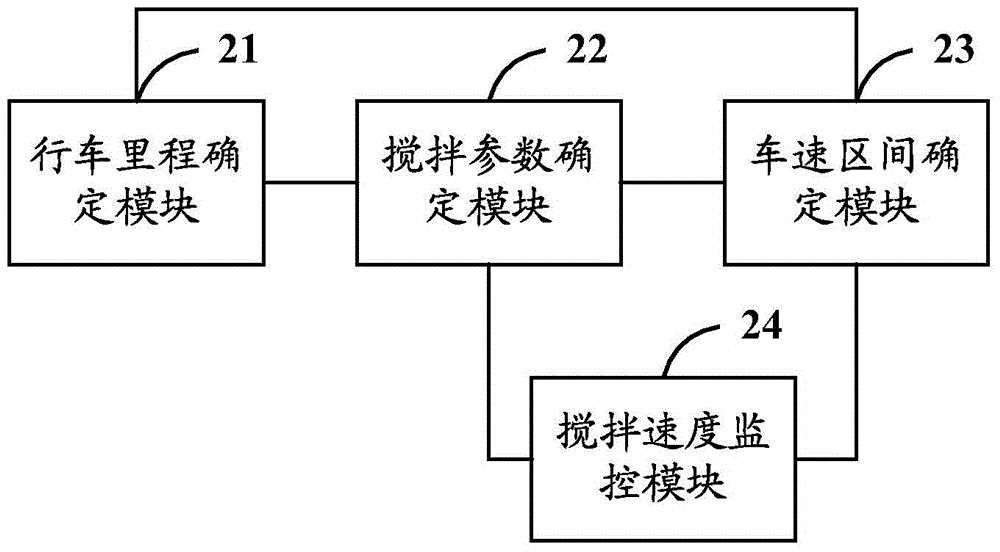

[0062] Embodiment 2 of the present invention provides a mixing drum speed monitoring device, such as figure 2 As shown, it is a schematic structural diagram of the mixing drum speed monitoring device described in Embodiment 2 of the present invention. The mixing drum speed monitoring device may specifically include a driving mileage determination module 21, a stirring parameter determination module 22, a vehicle speed range determination module 23 and Stirring speed monitoring module 24, wherein:

[0063] The mileage determination module 21 can be used to determine the mileage corresponding to the current driving process of the mixer truck according to the navigation positioning data information and the start and end point information corresponding to the current driving process of the mixer truck; wherein, the navigation positioning data information can be Navigation and positioning data information based on GPS, or, navigation and positioning data information based on Beido...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com