Improved torpedo anchor

An improved, torpedo anchor technology, applied in anchor points, ship parts, transportation and packaging, etc., can solve the problems of inconvenient removal, large mass and volume of torpedo anchors, etc., to achieve easy removal, increased anchoring effect, quality and Volume reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and example the present invention will be further described:

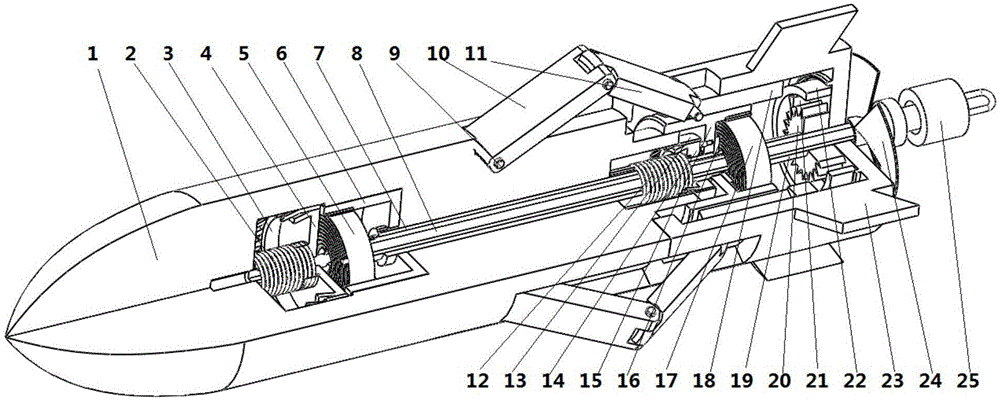

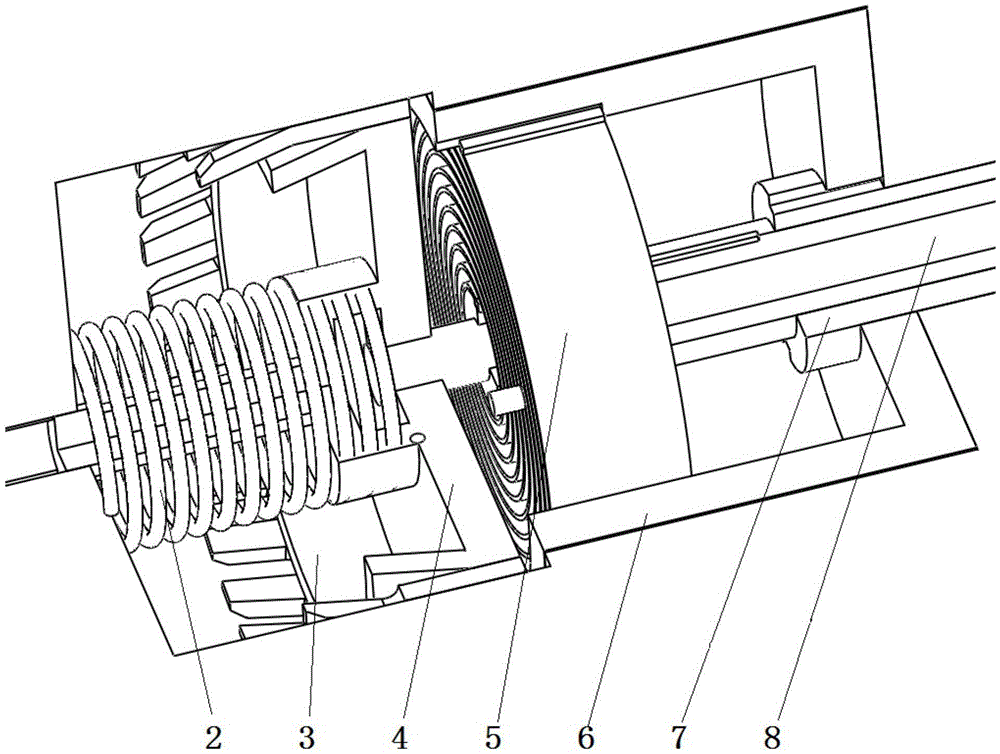

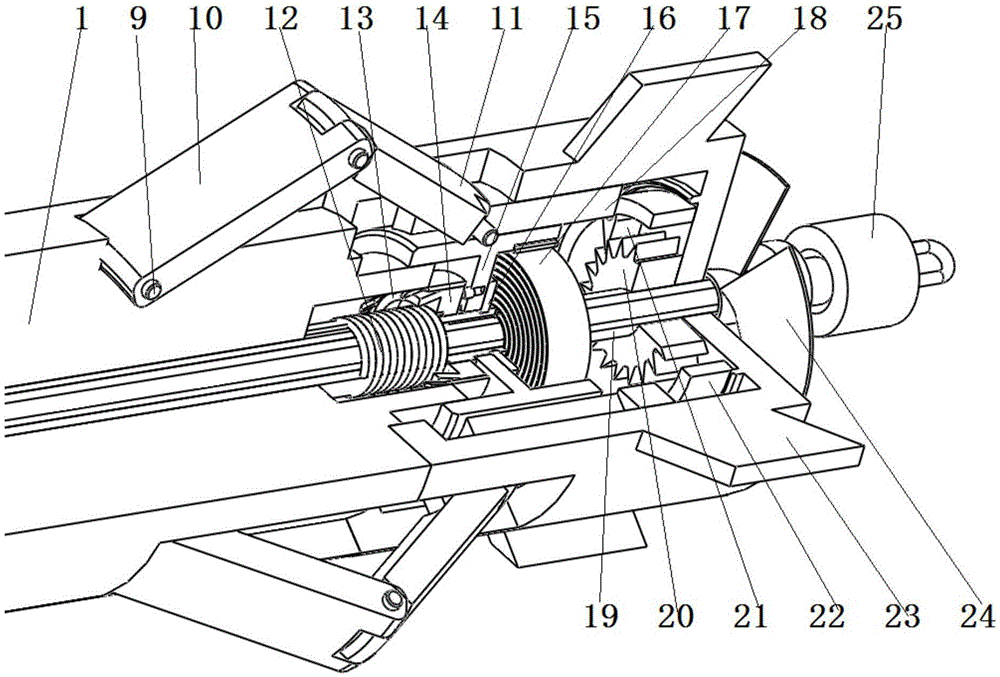

[0014] Such as figure 1 , figure 2 , image 3 As shown, the improved torpedo anchor includes torpedo anchor main body 1, bottom spring 2, bottom claw 3, bottom locking plate 4, bottom torsion spring 5, bottom torsion spring outer mounting frame 6, reset sleeve 7, and main bearing rod 8. Connecting pin 9, lower support plate 10, upper support plate 11, upper spring 12, upper claw 13, upper locking plate 14, upper torsion spring outer mounting frame 15, snap ring 16, upper torsion spring 17, feed frame 18. Torque transmission tube 19, ratchet 20, pawl 21, pawl mounting frame 22, empennage housing 23, spiral wing 24, reset counterweight 25; the bottom spring 2 is installed on the front part of the torpedo anchor main body 1, and is connected with The bottom locking plate 4, the bottom claw 3 is fixedly connected to the front part of the torpedo anchor body 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com