Demountable spinning bobbin

A bobbin and tube body technology, applied in the field of detachable textile bobbins, can solve the undisclosed problems of how to disassemble and assemble caps and strands, increase production costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

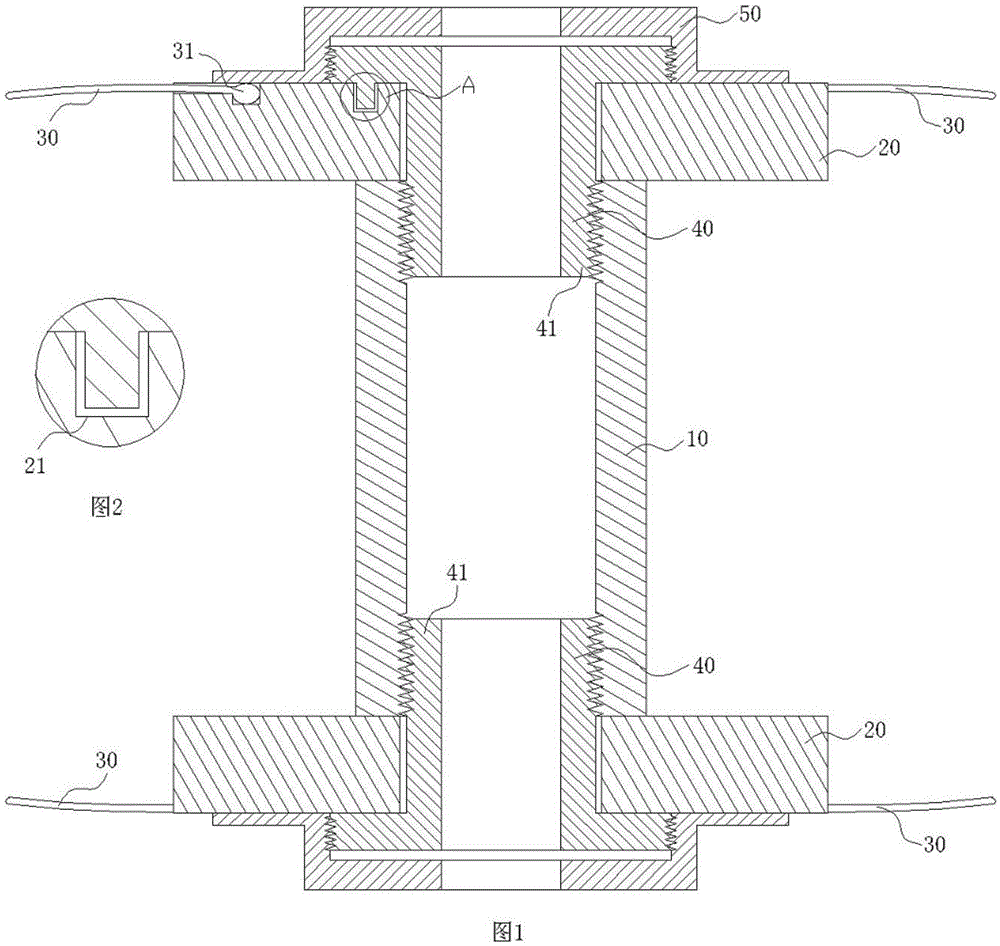

[0023] Such as Figure 1~4 As shown, a detachable textile bobbin tube includes a tube body 10 , side plates 20 installed at both ends of the tube body 10 , and several whiskers 30 installed on the side plates 20 . Wherein, the side plate 20 is made of plastic with smooth surface and smooth and edgeless edges. The whiskers 30 are soft plastic strips, and the whiskers 30 are evenly distributed along the circumference.

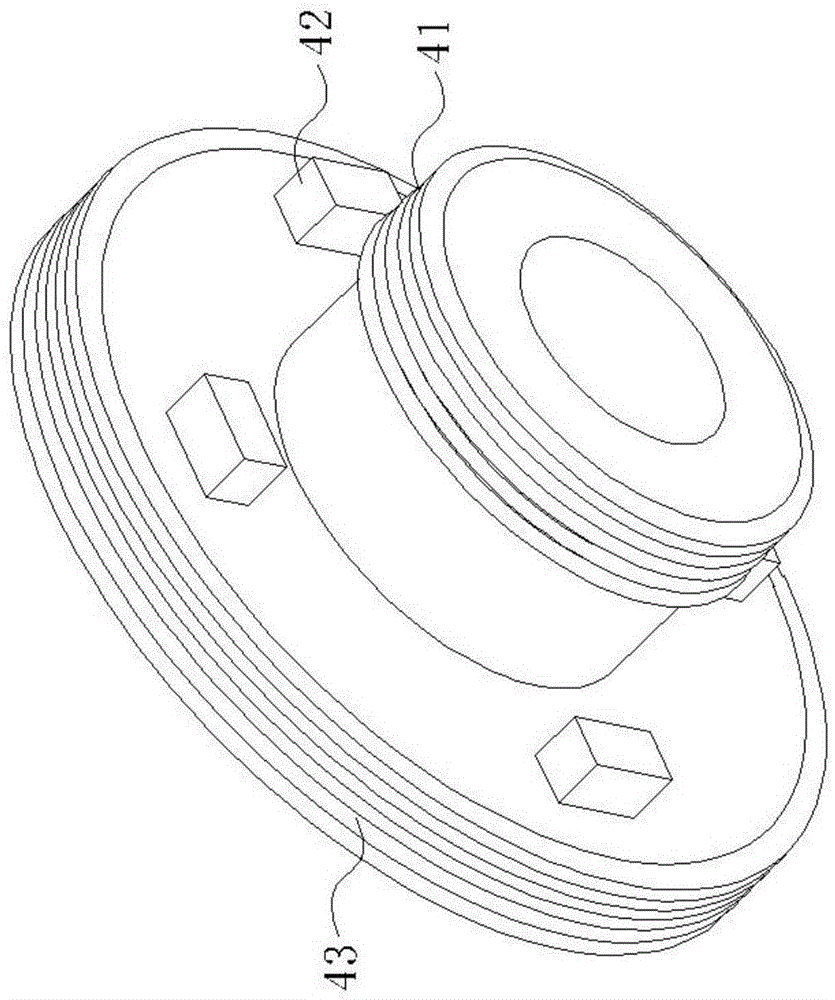

[0024] Also includes a threaded connector 40, one end 41 of the threaded connector is provided with an external thread, the threaded connector 40 is provided with several protruding blocks 42, and both ends of the pipe body 10 are provided with the threaded connector 40 The external thread is matched with the internal thread. The side plate 20 is provided with several grooves 21 that match the protruding blocks 42 . The side plate 20 is installed on both ends of the pipe body 10 through threaded connectors 40 .

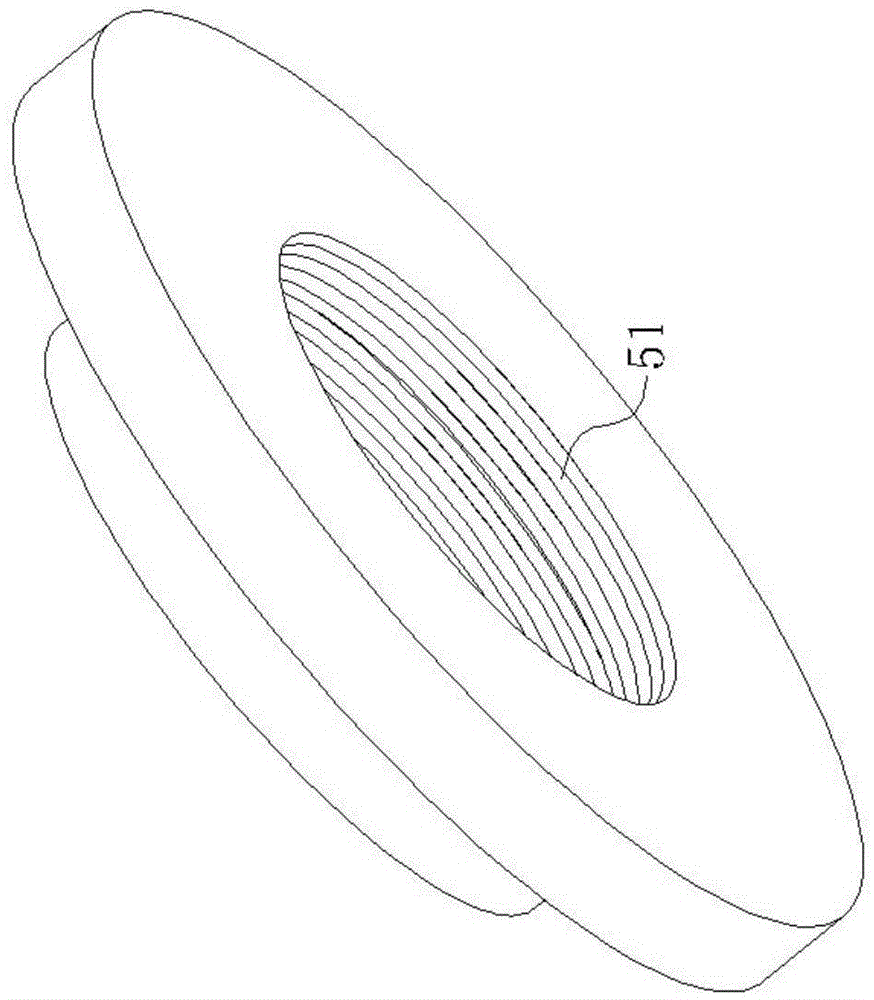

[0025] Also includes a gland 50, the gland 50 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com