Electroplating device and continuous vertical electroplating production line

A technology of electroplating device and electroplating tank, which is applied in the direction of electrolysis process, electrolysis components, charge manipulation, etc., to achieve the effect of simplifying the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

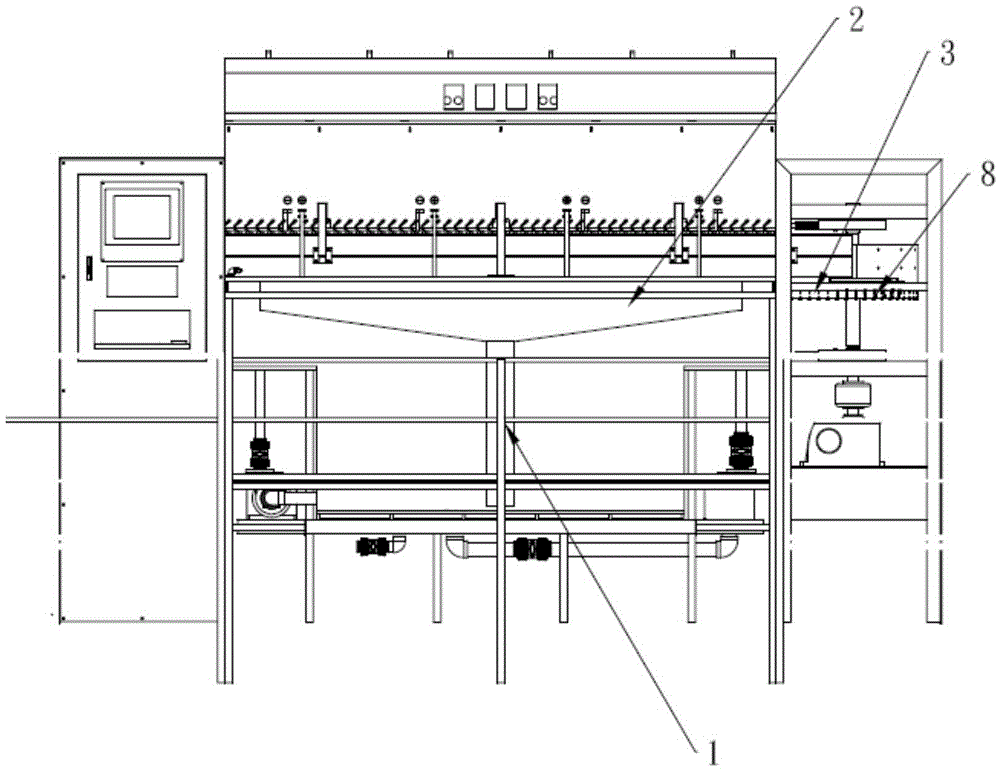

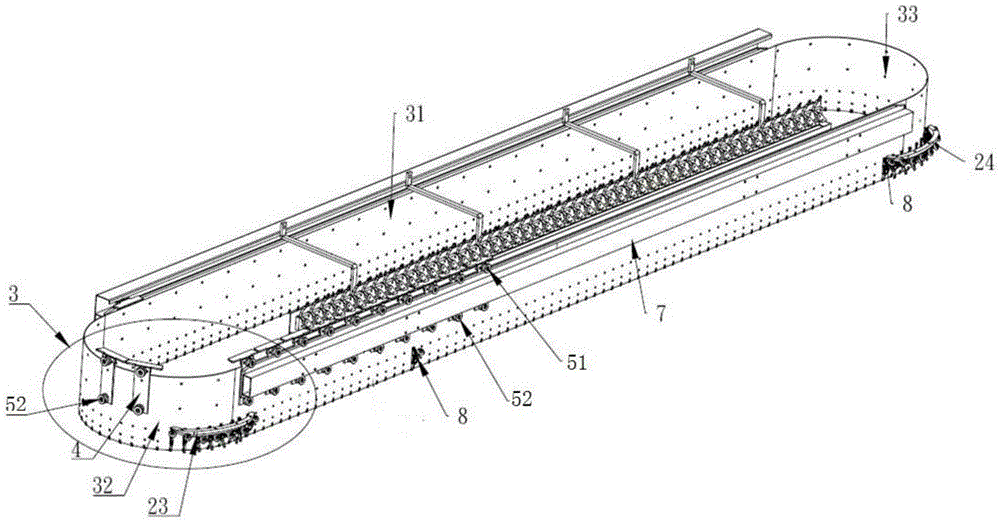

[0081] Such as figure 1 Shown, the present embodiment provides an electroplating device, comprising

[0082] Rack 1;

[0083] The electroplating tank 2 is arranged on the frame 1 and has an inlet and an outlet for the input and output of the substrate;

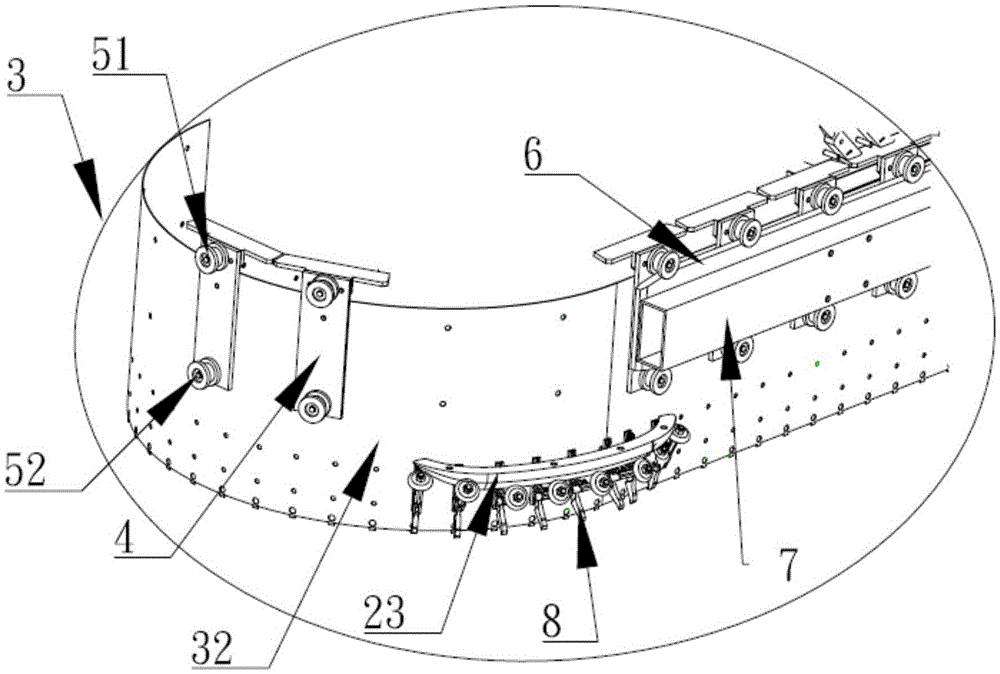

[0084] The conveyor belt 3 is arranged in the electroplating tank 2, and is used to drive the substrate fixed on the bottom thereof to move horizontally in the electroplating tank 2;

[0085] The limit mechanism is arranged on the frame 1 and is used to limit the downward movement of the conveyor belt 3 when the conveyor belt 3 moves.

[0086] In the electroplating device with the above-mentioned structure, during the moving process of the conveyor belt 3, the limit mechanism can limit the downward movement of the conveyor belt 3, so that the conveyor belt 3 keeps running at the same height in the electroplating tank 2, so that the bottom edge of the conveyor belt 3 can be fixed. The substrates run at the same height to ens...

Embodiment 2

[0135] This embodiment provides a continuous vertical electroplating production line, comprising

[0136] Continuous feeding system for continuous output of substrates;

[0137] The electroplating device is used for electroplating the substrate input into the electroplating tank 2 by the continuous feeding system;

[0138] The continuous receiving system is used to continuously collect the substrates output in the electroplating tank 2 into rolls;

[0139] The above-mentioned electroplating device is any one of the electroplating devices described in Embodiment 1.

[0140] This vertical electroplating production line adopts any one of the electroplating devices described in Embodiment 1, so that the conveyor belt 3 runs at the same height all the time in the electroplating tank 2, and ensures that the substrates fixed on the bottom edge of the conveyor belt 3 run at the same height, so that the substrates can be operated at the same height during electroplating. The tank 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com