Preparation method of anti-oxidative brocade gold and silver threads

A gold and silver thread, anti-oxidation technology, applied in the field of brocade weaving, can solve the problems of unusable, soft wax layer of gold and silver thread, wax not wear-resistant, etc., to achieve the effect of avoiding leakage, uniform thickness and thin diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

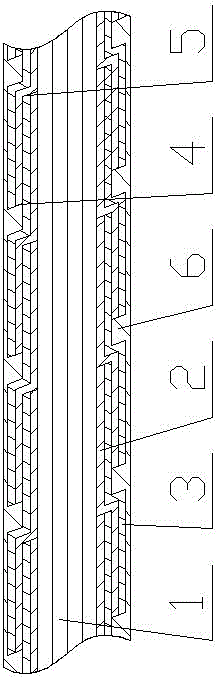

[0031] Such as figure 1 Shown, the present invention comprises the following steps:

[0032] 1) A gold and silver foil layer 2 is fixed on one end surface of the film base layer 3 by magnetron sputtering;

[0033] 2) Twisting a plurality of core wires 1 into strands;

[0034] 3) The film base layer 3 fixed with the gold and silver foil layer 2 is wound and fixed on the surface of the core wire 1 to form a gold and silver wire, and the gold and silver foil layer 2 is located between the core wire 1 and the film base layer 3;

[0035] 4) Pass the gold and silver wire through the paint liquid and through the through hole of the mold;

[0036] 5) Dry the gold and silver wires passing through the through holes of the mold;

[0037] 6) Repeat step 4) and step 5) until the surface of the paint layer is flat.

[0038]In the step 2), the plurality of core wires 1 are divided into 2 bundles or 3 bundles and twisted into strands; in the step 3), the gold and silver foil layer 2 after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com