Grinding machine for weld joint in rail flange of steel rail

A grinding machine and rail bottom technology, which is applied in the direction of track, track laying, track maintenance, etc., can solve the problems of rail bottom grinding construction difficulties, shorten the fatigue life of rails, etc., and achieve the effect of convenient grinding and smooth weld seam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

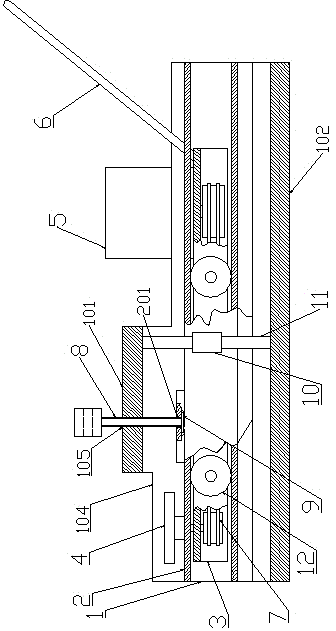

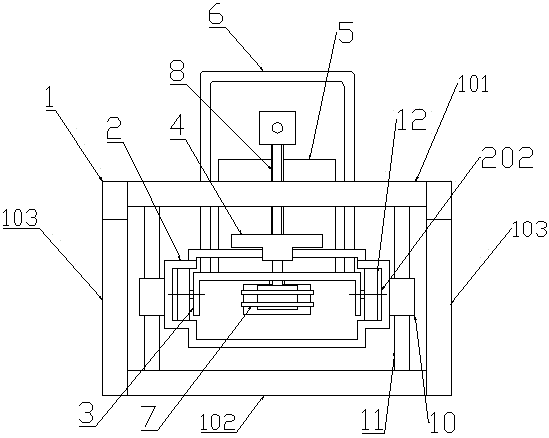

[0016] As shown in the figure, a rail bottom weld seam grinder includes a support frame 1 composed of a top plate 101, a bottom plate 102, and front and rear side plates 103. A gap 104 is provided at the upper left corner of the front and rear side plates 103 of the support frame 1 to support The inside of the frame 1 is provided with a lifting frame 2, and the inside of the lifting frame is provided with a slide plate 3 that can slide left and right. The left side of the top of the slide plate 3 is provided with a grinding wheel 4, and the right side is provided with a motor 5 and a handrail 6 from the inside to the outside. A belt transmission mechanism 7 is provided between 4 and the motor 5 . The support frame top plate 101 is provided with a threaded hole 105, and the corresponding support frame 1 threaded hole 105 place is provided with a through hole 201 on the lifting frame 2 top plate. In the threaded hole 105 on the top plate of the support frame and through the thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com